Ultrasonic Wide Area Spray Nozzle

Application

1. Nanoparticle coatings: Ultrasonic Wide Open Mist Fan Shaped Area Spraying Nozzle System can effectively disperse and evenly spray nanoparticle coatings. Due to the unique properties of nanoparticles, such as high specific surface area and enhanced functionality, ultrasonic spraying technology can help achieve efficient coating of nanoparticle coatings and provide advantages in material performance.

2. Coating for electronic devices: Ultrasonic Wide Open Mist Fan Shaped Area Spraying Nozzle System can achieve precise control of thin film coatings, such as optical thin films, barrier films, conductive films, etc. In addition, ultrasonic spraying technology can process high solid content electronic coatings and provide uniformly dispersed and highly adhesive coatings.

3. Drug delivery system: Ultrasonic Wide Open Mist Fan Shaped Area Spraying Nozzle System can be used to spray nano particle carriers, microspheres, or films to achieve controlled release, targeted delivery, and enhanced biocompatibility of drugs. Ultrasonic spraying technology can maintain the activity of drugs and improve their stability and delivery efficiency by forming a uniform coating.

4. Food industry: Ultrasonic Wide Open Mist Fan Shaped Area Spraying Nozzle System can help spray food coatings, such as protective coatings, seasoning coatings, and nutrient additive coatings. Ultrasonic spraying technology can achieve uniform distribution and thickness control of coatings, thereby improving the quality, freshness, and taste of food.

2. Coating for electronic devices: Ultrasonic Wide Open Mist Fan Shaped Area Spraying Nozzle System can achieve precise control of thin film coatings, such as optical thin films, barrier films, conductive films, etc. In addition, ultrasonic spraying technology can process high solid content electronic coatings and provide uniformly dispersed and highly adhesive coatings.

3. Drug delivery system: Ultrasonic Wide Open Mist Fan Shaped Area Spraying Nozzle System can be used to spray nano particle carriers, microspheres, or films to achieve controlled release, targeted delivery, and enhanced biocompatibility of drugs. Ultrasonic spraying technology can maintain the activity of drugs and improve their stability and delivery efficiency by forming a uniform coating.

4. Food industry: Ultrasonic Wide Open Mist Fan Shaped Area Spraying Nozzle System can help spray food coatings, such as protective coatings, seasoning coatings, and nutrient additive coatings. Ultrasonic spraying technology can achieve uniform distribution and thickness control of coatings, thereby improving the quality, freshness, and taste of food.

0102030405

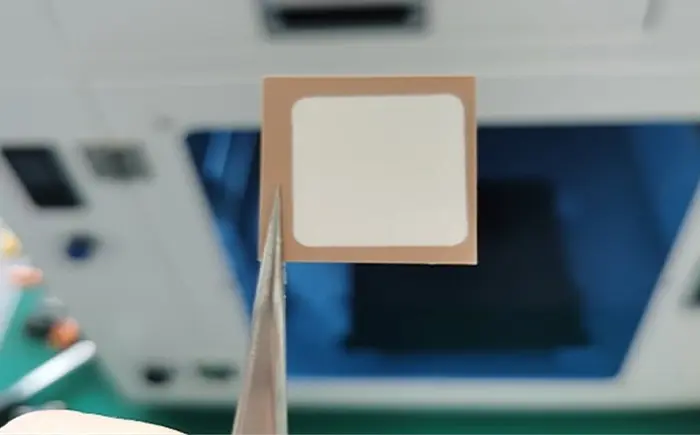

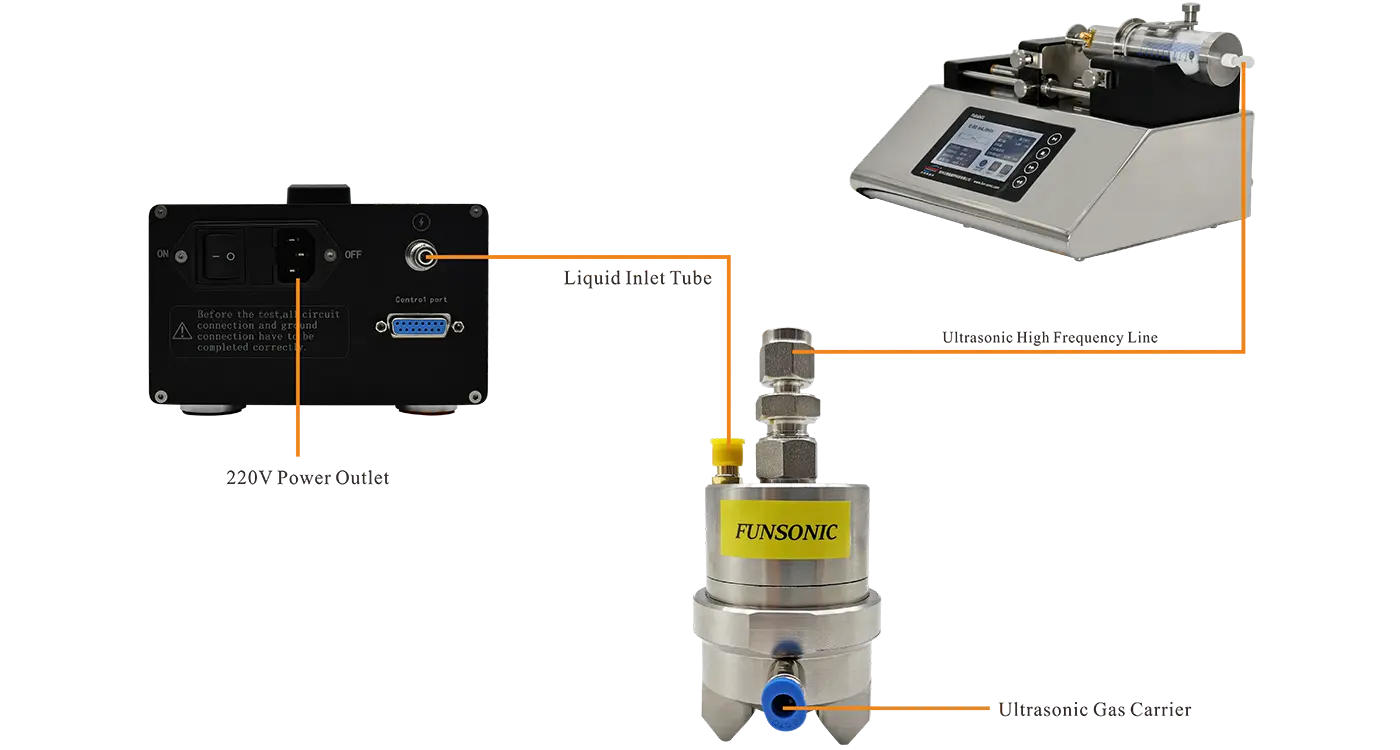

Demobstration

0102