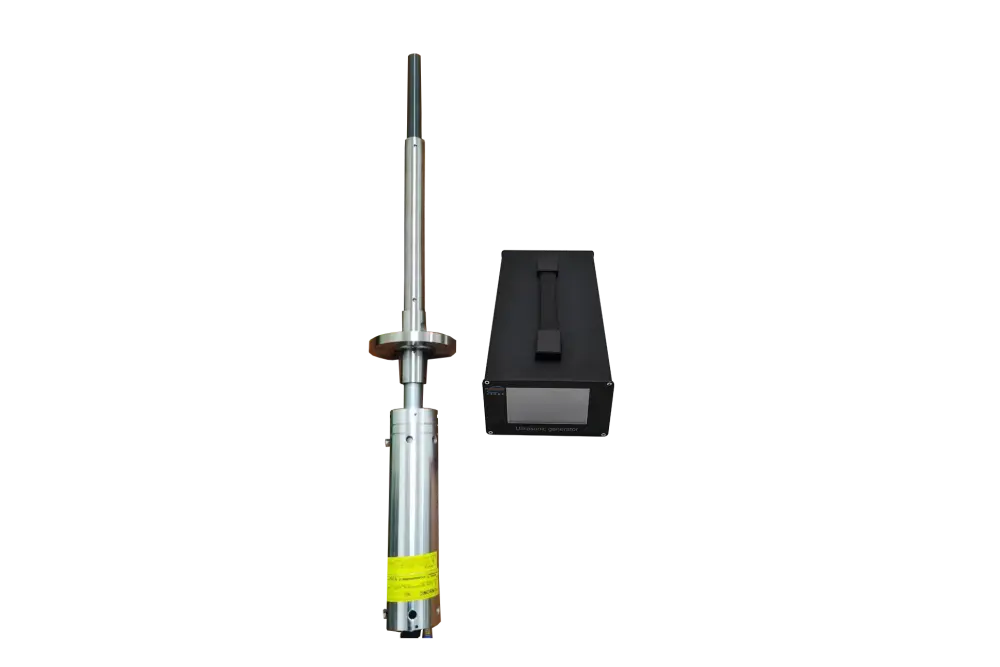

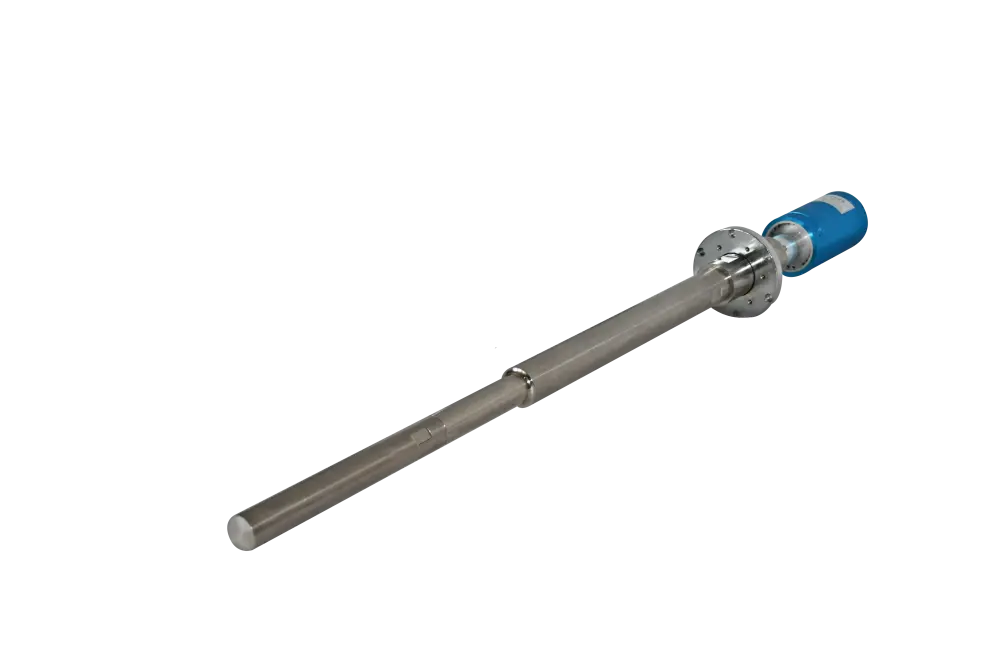

Ultrasonic Superconducting Wire Indium Coating Machine

Principle

Advantages

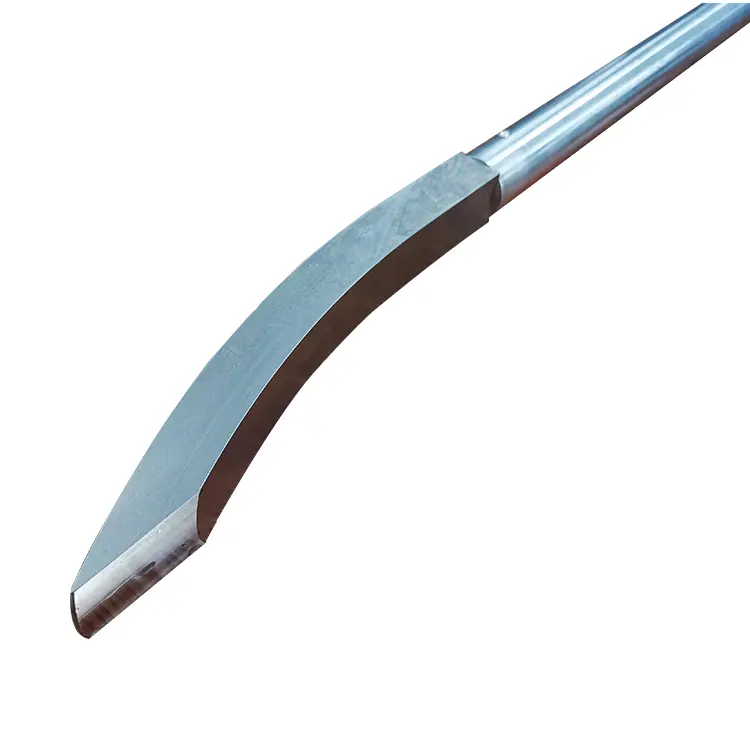

◆ The coating is uniform and firm: Ultrasonic technological know-how ensures that the indium coating has no blind spots or ripples, and the thickness can be exactly managed inside 0.02mm. High-frequency vibrations expel microbubbles, making the indium and substrate tightly bonded and now not convenient to fall off.

◆ Efficient production: It only takes 15 minutes to coat large-sized materials (such as 1500×190mm copper plate), and only 1 minute to coat small-sized materials (such as 50×50mm ITO glass). Compared with regular guide scraping, the effectivity is multiplied various times.

◆ Environmentally pleasant and pollution-free: No flux is required, dangerous gases and wastewater emissions are avoided, it complies with inexperienced manufacturing standards, and reduces chemical waste cure costs.

◆ Reduce manufacturing costs: Aluminum wire can exchange high priced copper wire, saving about 80% of fabric costs. Reduce the use of flux and subsequent cleaning processes, and reduce equipment and labor costs.