Ultrasonic Stitching: Seamless Fabric Joining Benefits and Efficiency Explained

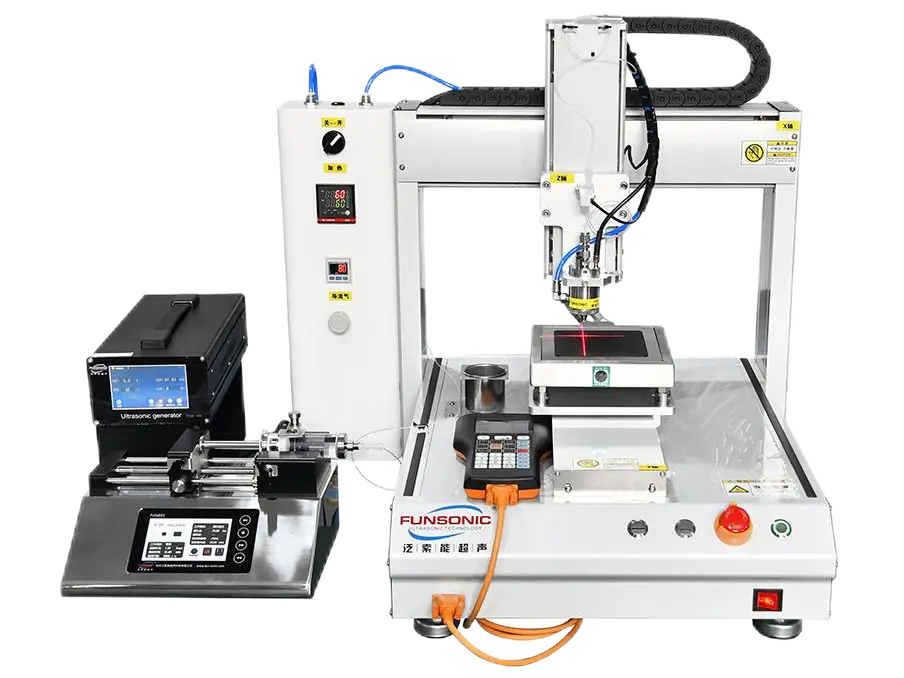

Ultrasonic Stitching has transformed my perspective on manufacturing with its remarkable efficiency and precision. As a manufacturer, I benefit from the innovative bonding techniques that work seamlessly across various materials. This technology reduces labor costs while enhancing the durability of products, a vital factor for B2B operations. Hangzhou FUNSONIC Ultrasonic Technology Co., Ltd. stands out with its cutting-edge ultrasonic systems. Suitable for industries such as textiles, packaging, and automotive, this stitching method promises to boost product quality and streamline production processes. One of the key advantages of Ultrasonic Stitching is its capability to create clean seams without extra threads or adhesives, leading to significant time and material savings. Witnessing firsthand how businesses can increase output and decrease waste has been enlightening. Investing in ultrasonic technology could significantly elevate your manufacturing effectiveness and drive your production forward.