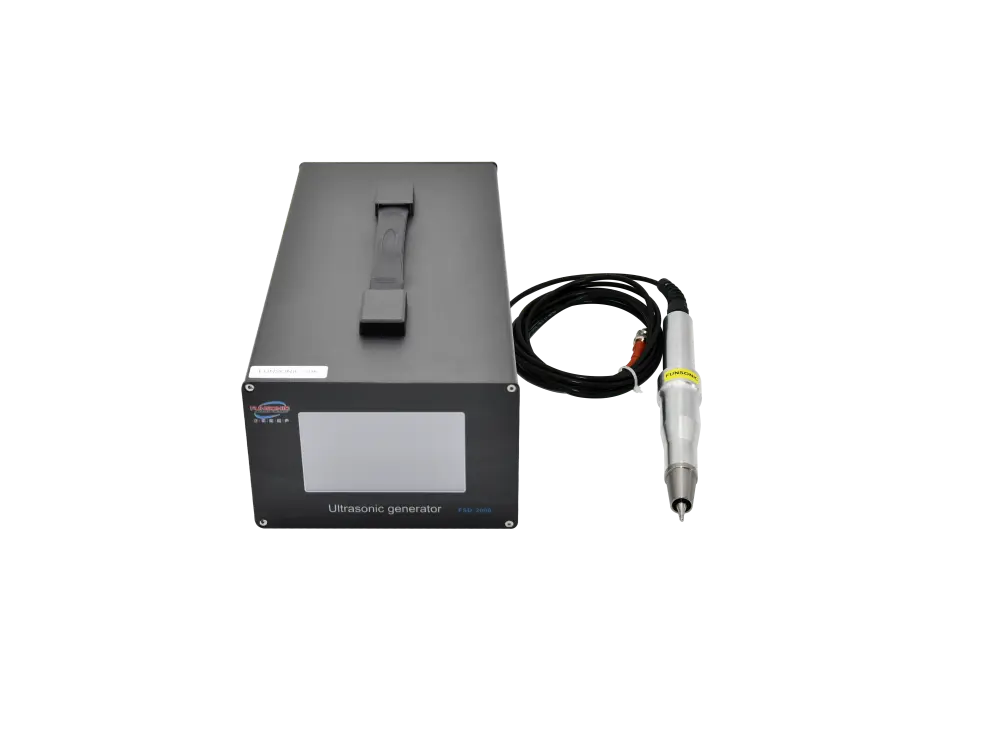

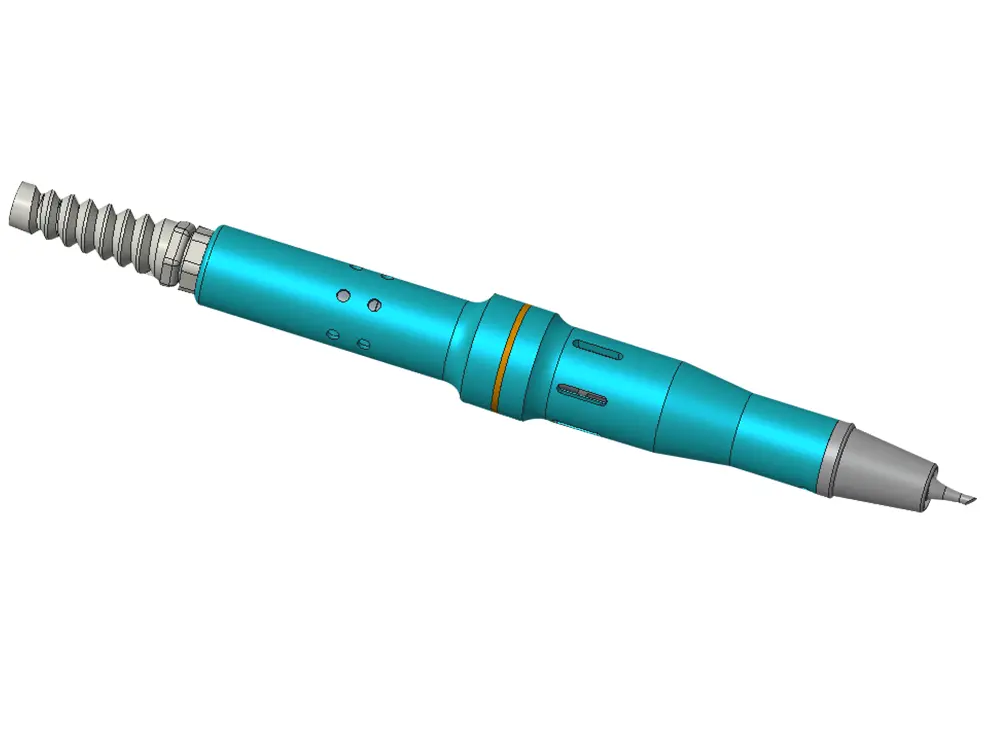

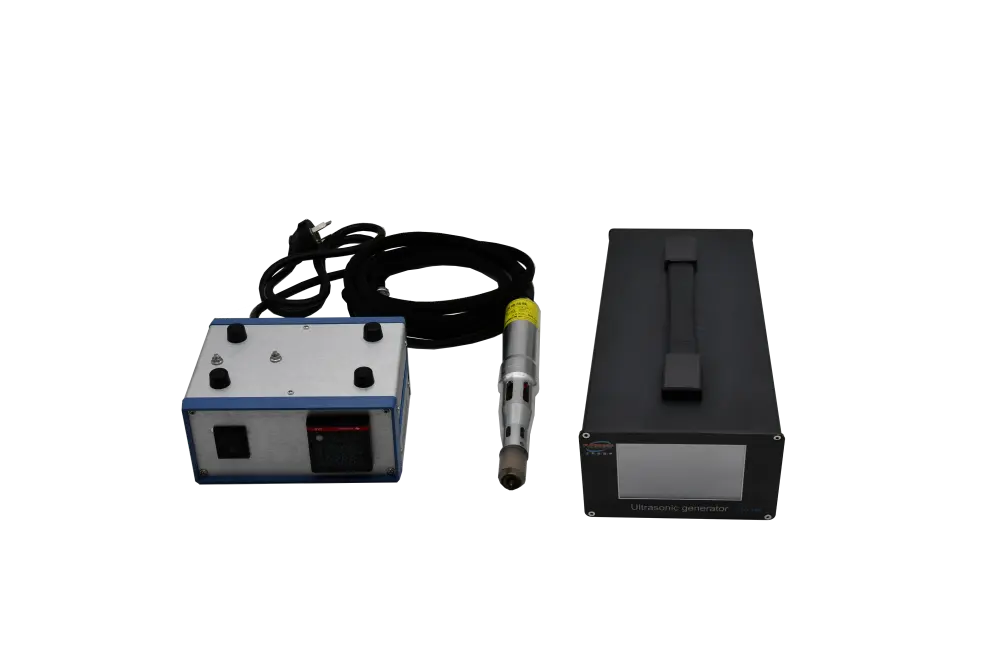

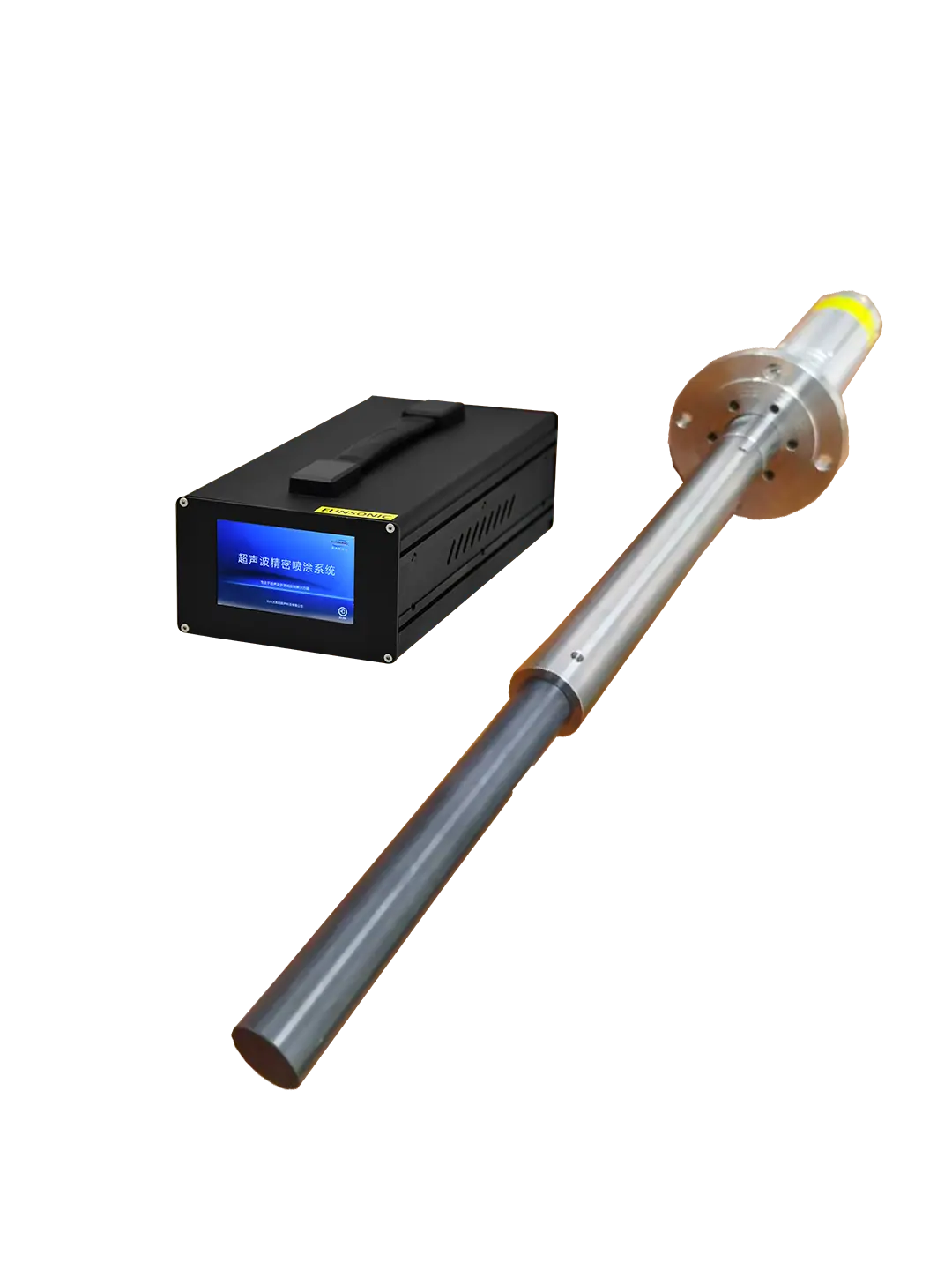

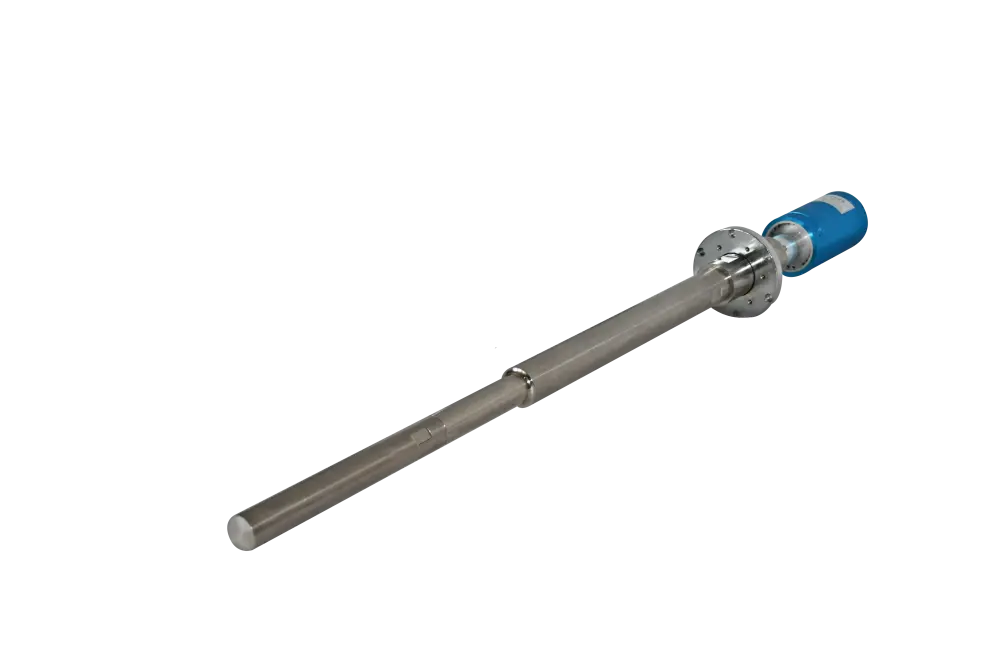

Ultrasonic Soldering Iron System

Principle

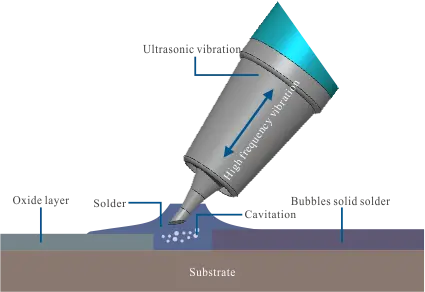

High-energy ultrasonic vibrations create cavitation in the liquid solder to remove the oxide film on the surface of the base material to be welded. High pressure forces the liquid solder into the micropores and cracks of the base material, sealing these micropores and cracks, making the base material surface easier to weld. Ultrasonic vibration squeezes out the bubbles in the liquid solder, achieving a perfect weld without pores on the surface. The ultrasonic soldering process has good welding effect and high quality.

Electric soldering iron is one of the best choices for flux-free, high-quality ultrasonic welding. The combination of flux and heating is a typical part of the standard welding process. Flux, as a strong chemical agent to clean the welding surface, produces harmful fumes and requires additional post-cleaning treatment. The ultrasonic electric soldering iron is a new welding method based on heat and ultrasonic vibration, namely ultrasonic welding.

The ultrasonic welding method mechanically cleans the surface to be welded by cavitation caused by ultrasonic vibration. Ultrasonic welding does not use flux, so there is no smoke, and eliminates the cleaning process or any environmental pollution. Customers can weld on glass, ceramics, aluminum, molybdenum, etc. without using any organic substances.

The ultrasonic welding method mechanically cleans the surface to be welded by cavitation caused by ultrasonic vibration. Ultrasonic welding does not use flux, so there is no smoke, and eliminates the cleaning process or any environmental pollution. Customers can weld on glass, ceramics, aluminum, molybdenum, etc. without using any organic substances.

Advantages

◆ Oscillator output power up to 70W even under high stress loads.

◆ Two oscillator power switches: foot switch and standard manual switch.

◆ Power load changes during soldering do not affect the overall reliability of the bonded solder due to automatic frequency regulatio.

◆ Solder temperature can be quickly adjusted and increased by continuous monitoring of the soldering tip temperature.

◆ Standardized temperature and oscillation output power, temperature and oscillation can be controlled via LAN.

◆ Small, compact design allows easy replacement of workstations.

Demonstration

0102