Ultrasonic Metal Powder Machine

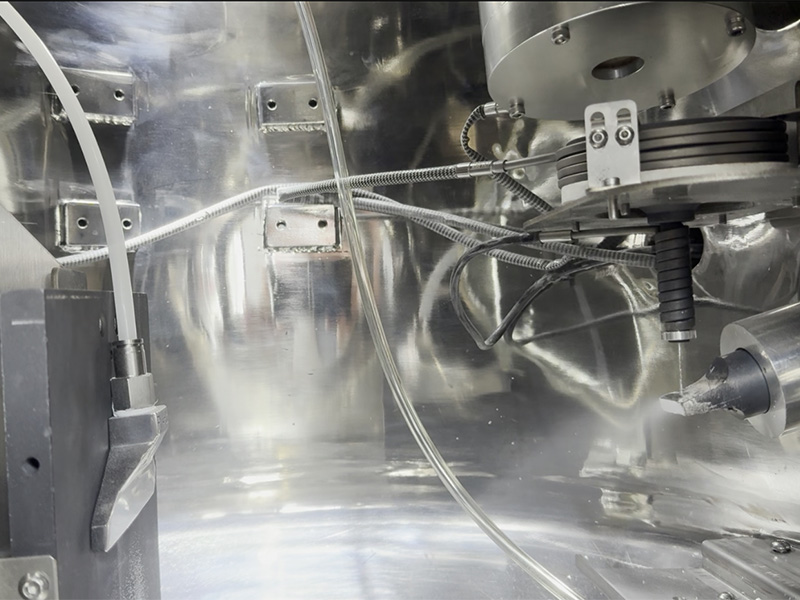

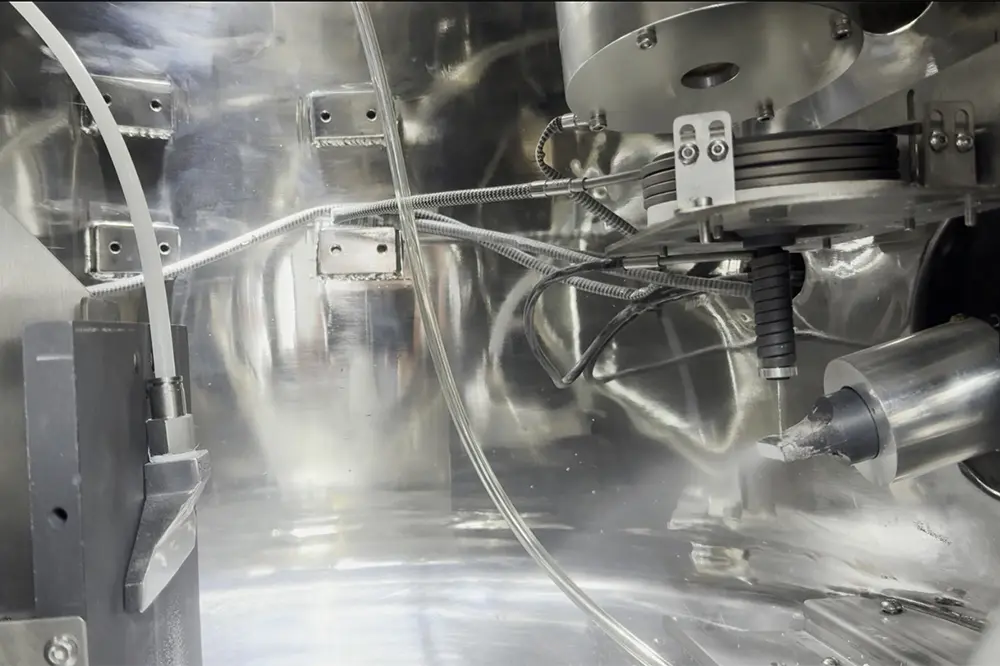

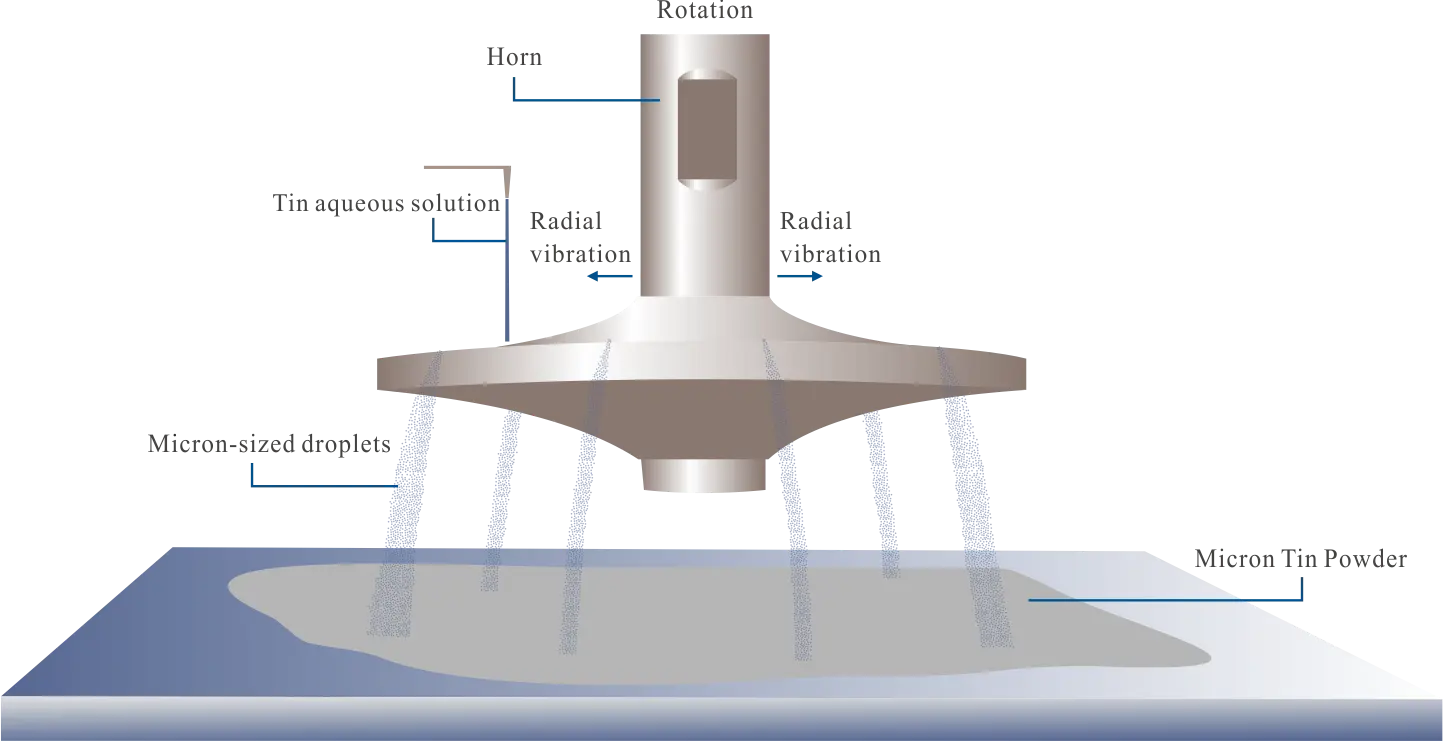

The vibration output quit of the transducer is related to the amplitude rod, and this longitudinal upward and downward vibration is transmitted from the amplitude rod to the atomization surface, producing standing waves. Another characteristic of the amplitude rod is to make bigger the output amplitude of the transducer to the favored level. When the molten steel liquid passes via the atomization surface, it is damaged into uniform micrometer sized droplets and mist, attaining atomization. Under the motion of rotational centrifugal pressure and standing waves on the atomization surface, the atomized micrometer sized droplets are thrown out of the atomization floor and hastily solidified upon cooling with air, forming micrometer sized steel stable particles. Collecting these particles is the required instruction of metallic powder.

Advantages

◆ The organized powder has the benefits of excessive purity, low oxygen content, desirable sphericity and uniform particle dimension distribution.

◆ The tools and technique are simple, the operation is convenient, and the product fantastic is steady and controllable.

◆ Significant benefits consist of low power consumption, excessive utilization rate, and low cost.

◆ Ultrasonic atomization has the extremely good traits of environmental protection, electricity saving, low carbon and hygiene.