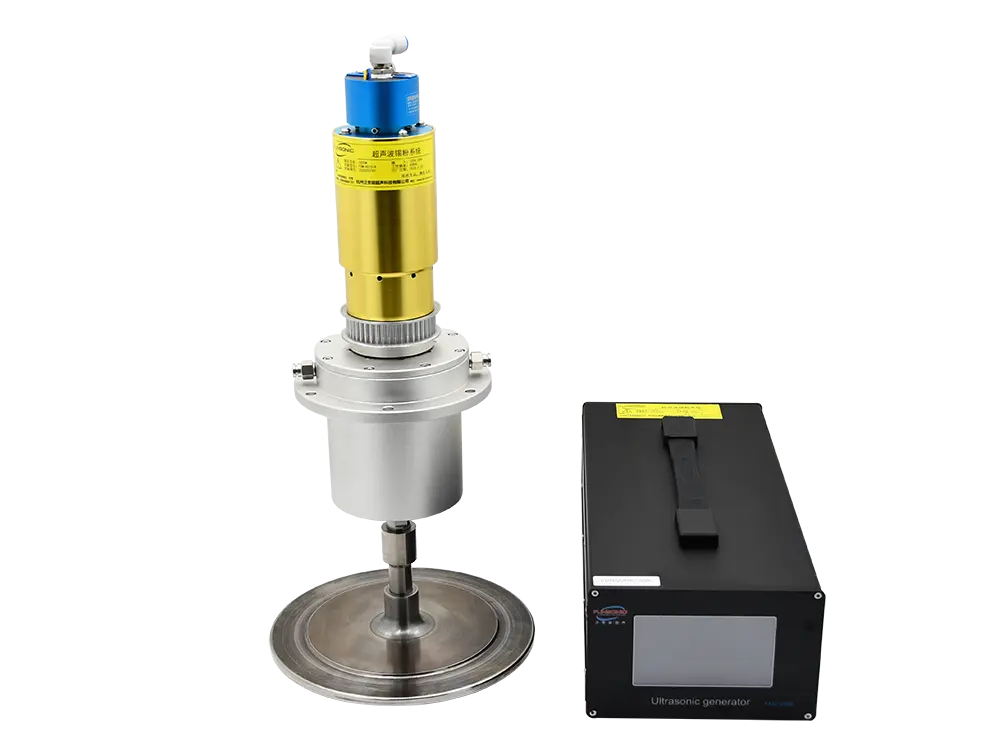

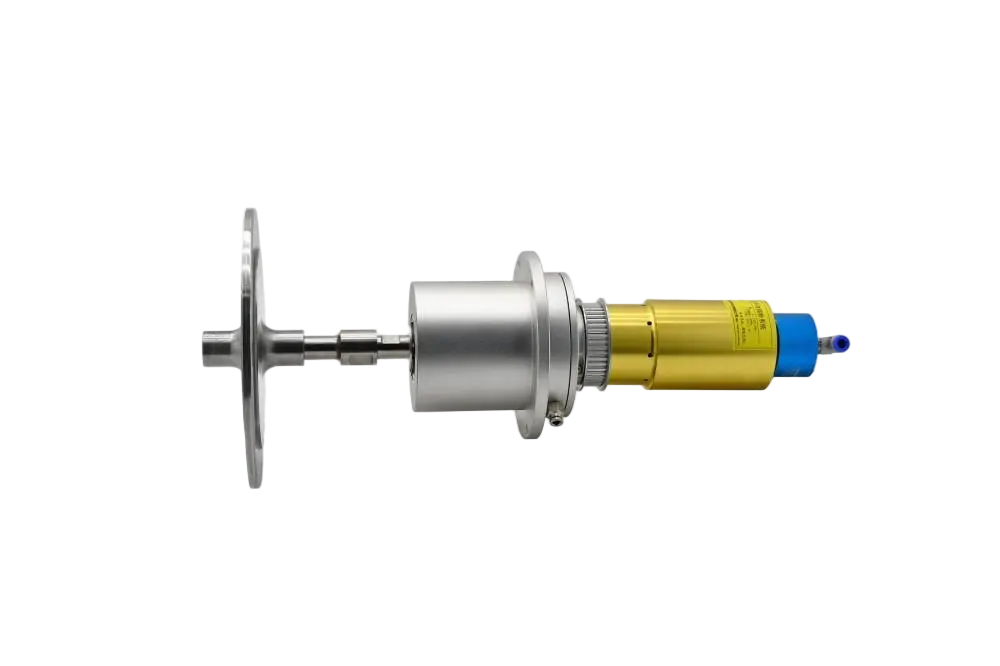

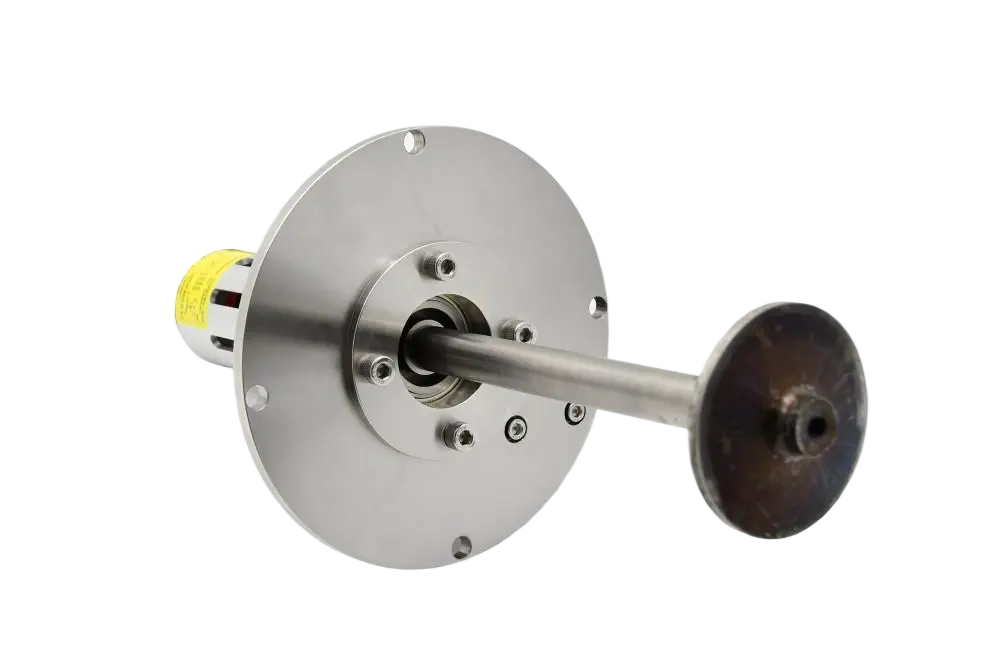

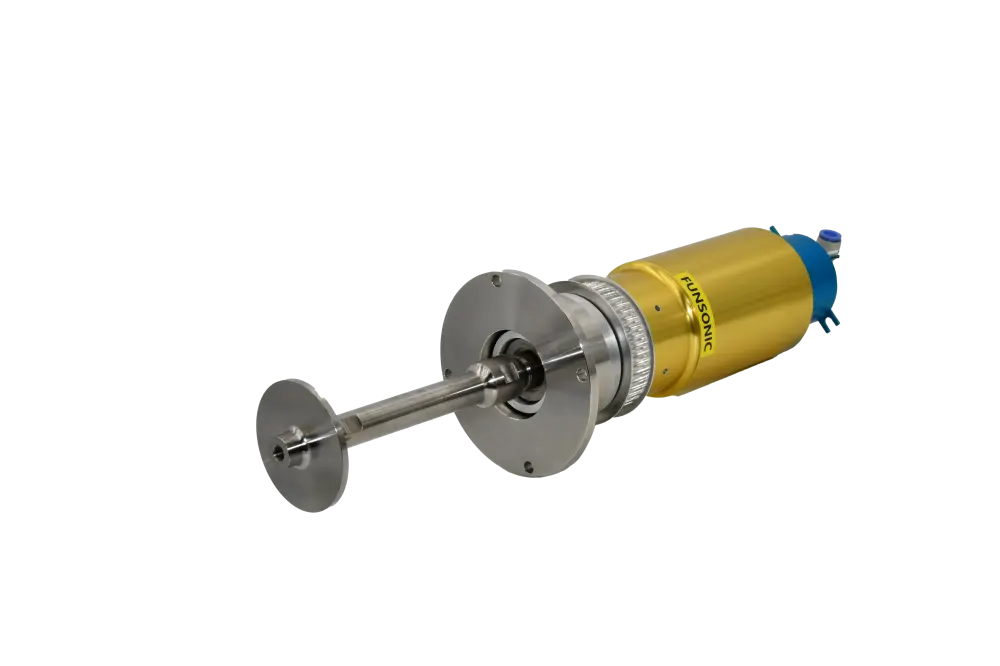

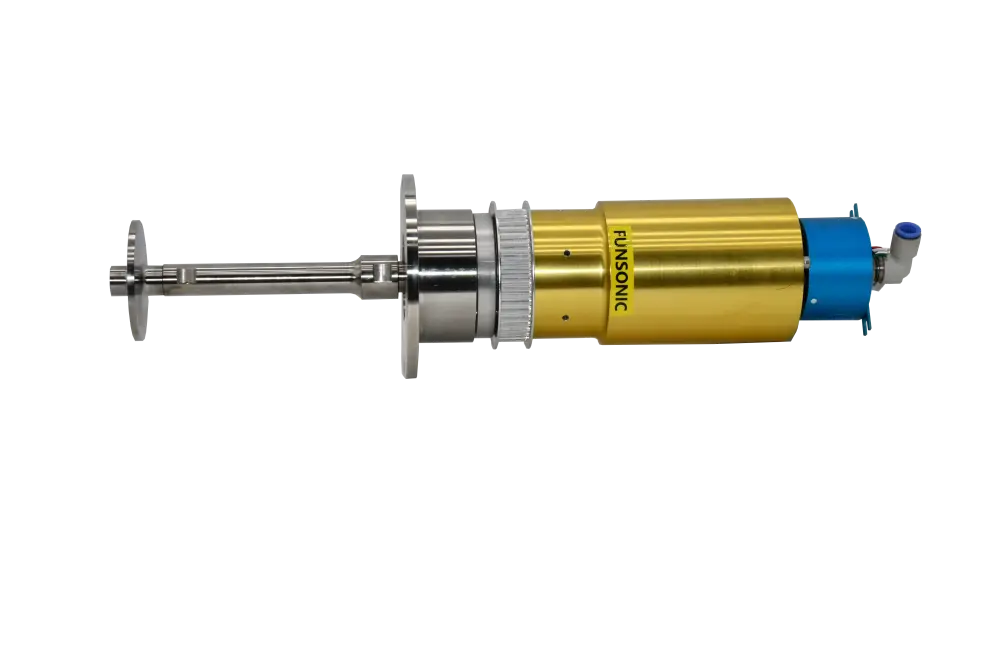

Ultrasonic Metal Powder Machine Core

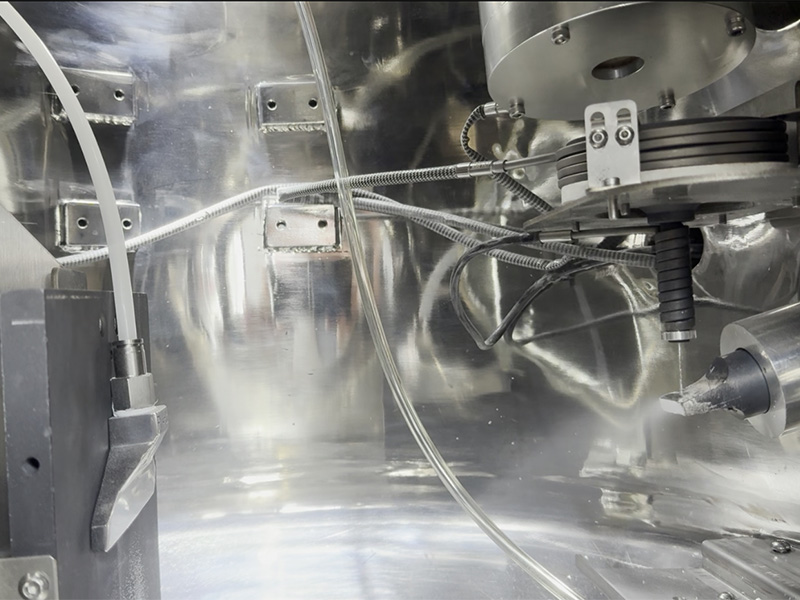

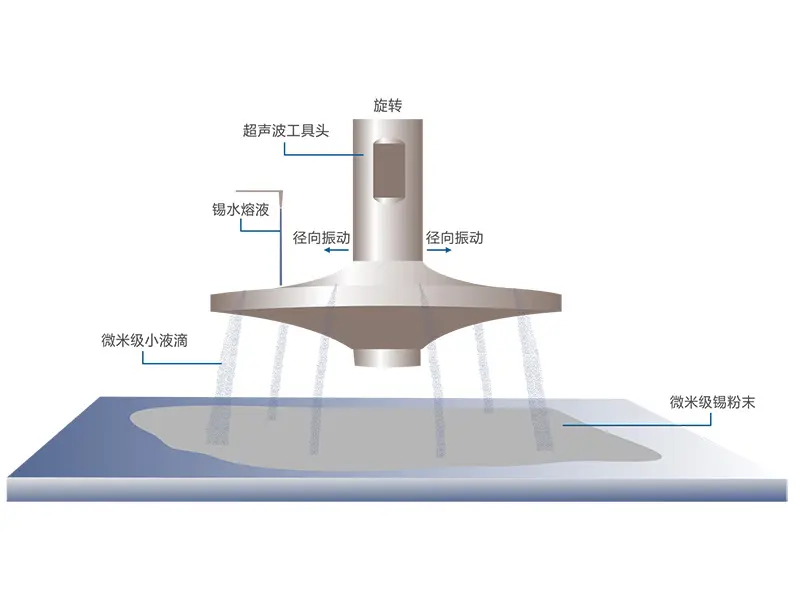

When the molten metal liquid passes through the atomization surface, it is broken into uniform micron-sized droplets and mist to achieve atomization. The atomized micron-sized droplets are thrown out of the atomization surface under the action of the rotating centrifugal force and standing waves of the atomization surface, and are rapidly solidified when cooled by air to form micron-sized metal solid particles. Collecting these particles is the metal powder to be prepared. Moreover, in the ultrasonic atomization process, the size of the micron-sized droplet mist can be accurately controlled, thereby accurately controlling the size of the metal powder. Ultrasonic tin atomization uses the energy of ultrasound to break up the molten tin to form tiny particles ranging from a few microns to more than 100 microns. This metal spray technology is widely used in the fields of industry and research and development, and will gradually replace traditional pressure spraying.

Advantages

◆ The prepared powder has the advantages of high purity, low oxygen content, good sphericity and uniform particle size distribution.

◆ The equipment and process are simple, the operation is convenient, and the product quality is stable and controllable.

◆ Significant advantages include low energy consumption, high utilization rate, and low cost.

◆ Ultrasonic atomization has the remarkable characteristics of environmental protection, energy saving, low carbon and hygiene.