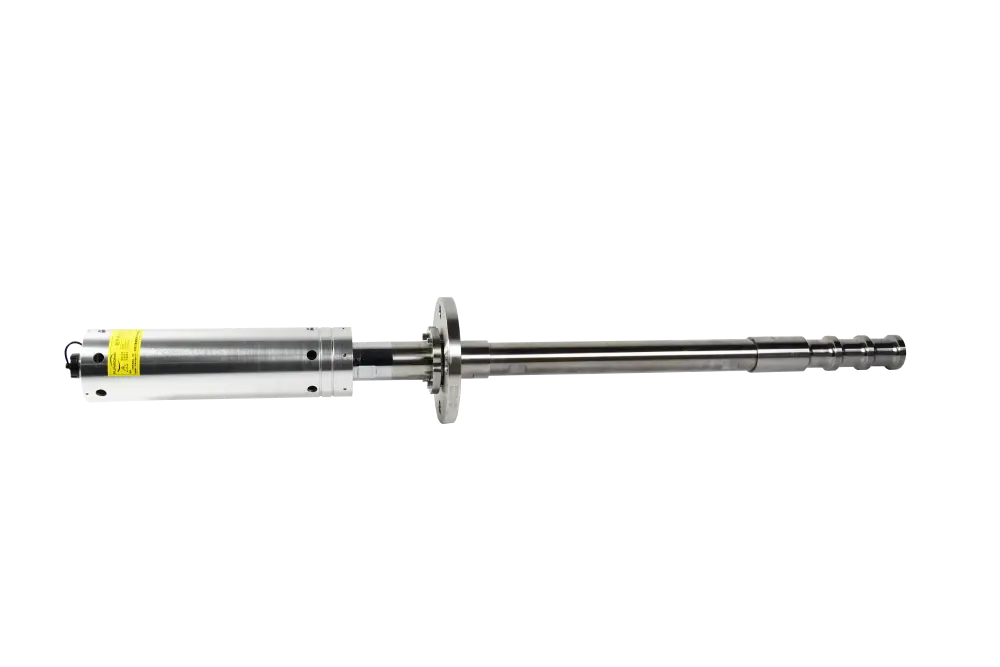

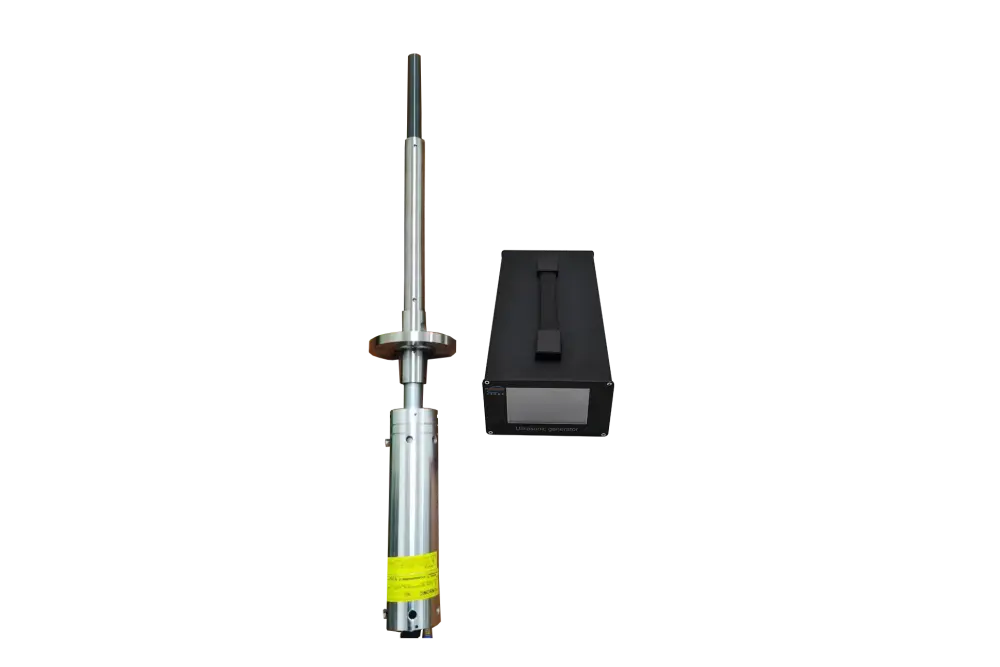

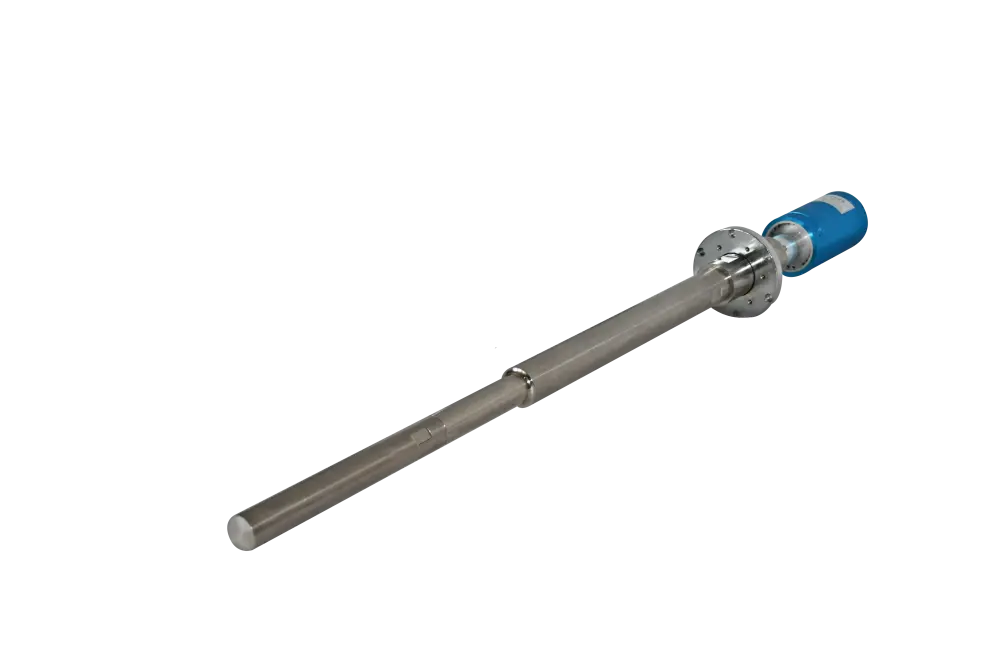

Ultrasonic Melt Metal Processing System

Principle

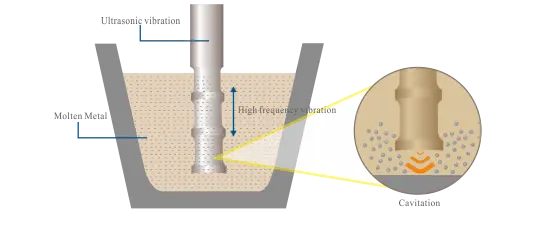

Ultrasonic metal melt treatment equipment uses the cavitation effect of ultrasound in the melt to cut off and destroy dendrites, impact the solidification front, increase stirring and diffusion, make the organization uniform, and at the same time increase the tensile strength of metal materials and improve the toughness of metals. Small grains and large boundary area can effectively prevent dislocation and intercrystalline slip, that is, it takes more force to break the material. The finer the grains, the smaller the dendrite spacing, the higher the yield strength, and the better the hardness. The ideal ingot structure is a uniform and fine equiaxed crystal on the entire cross section of the ingot. The equiaxed crystal has small anisotropy, uniform deformation during processing, excellent performance, good plasticity, and is conducive to casting and subsequent plastic processing. To obtain this structure, the best method at present is to use ultrasonic metal melt treatment equipment to perform ultrasonic refinement treatment on the melt.

When ultrasonic vibration treatment is used to produce castings, ultrasound will generate positive and negative alternating sound pressure during propagation to form a jet. At the same time, due to the nonlinear effect, acoustic flow and micro-acoustic flow will be generated, and ultrasonic cavitation will generate high-speed micro-jet at the solid-liquid interface. The cavitation effect in ultrasonic liquid can cut and destroy dendrites, impact the solidification front, increase stirring and diffusion, and achieve the effect of purifying the structure, refining the grains and homogenizing the structure. In addition to the mechanical effect of destroying dendrites caused by vibration, another important effect of ultrasonic vibration solidification is to increase the effective supercooling of molten metal, reduce the critical nucleus radius, thereby increasing the nucleation rate and refining the grains.

Advantages

◆ High temperature resistance: can withstand temperatures up to 800°C.

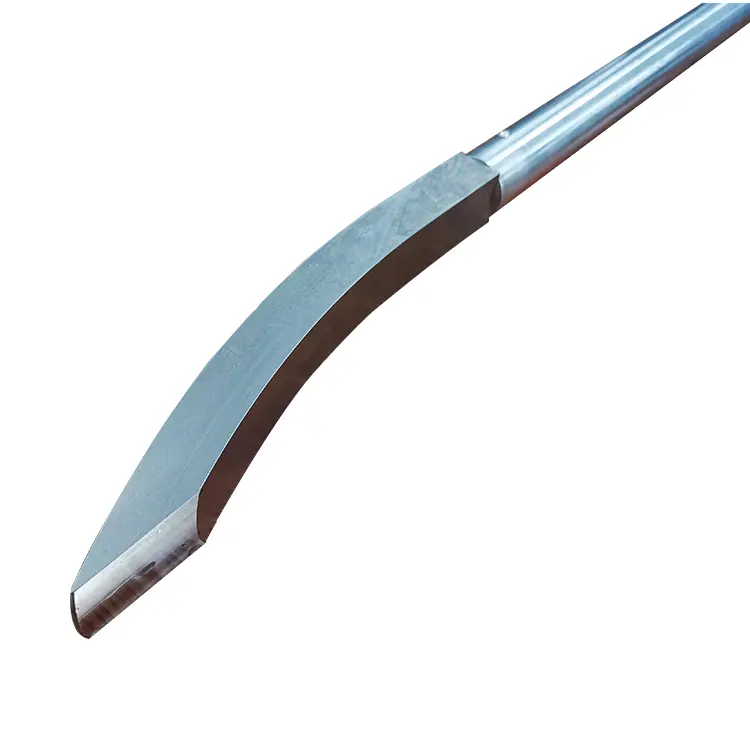

◆ Corrosion resistance: The tool head is made of high-strength titanium alloy and other materials..

◆ Good effect: The effect between micromolecules is direct and obvious.

◆ Good flowability: The friction between the tool and the processed material is reduced, and the fluidity of the material is greatly improved.

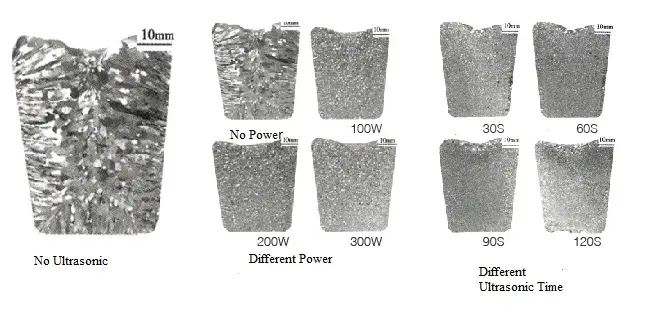

Demonstration

0102