Ultrasonic Line Array Coating System FS680

Advantage

Product Configuration

-

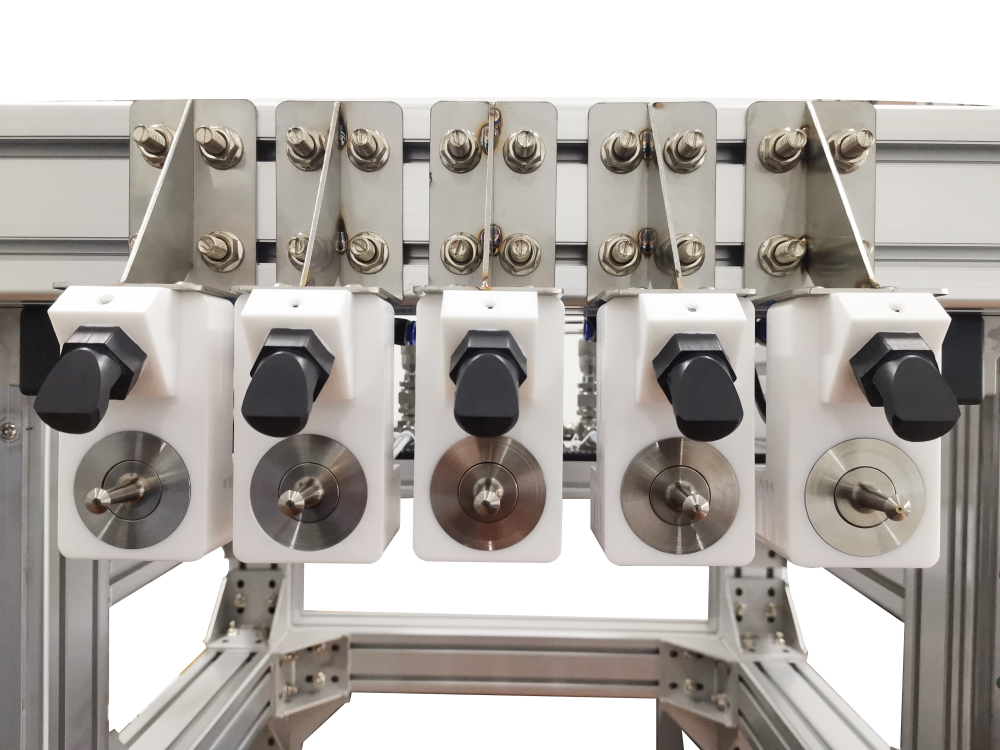

Conventional Arrangement

1. Ultrasonic nozzle: optional 20-200Khz multiple nozzle systems

2. Ultrasonic power supply: fully CNC precision power supply, fully intelligent frequency following, frequency tracking, stable performance

3. Liquid supply equipment: precision injection pump+biological grade sampler, liquid supply accuracy of 0.1 μ L/min

4. Sports system: XYZ three-axis imported servo motor+fully enclosed precision screw module

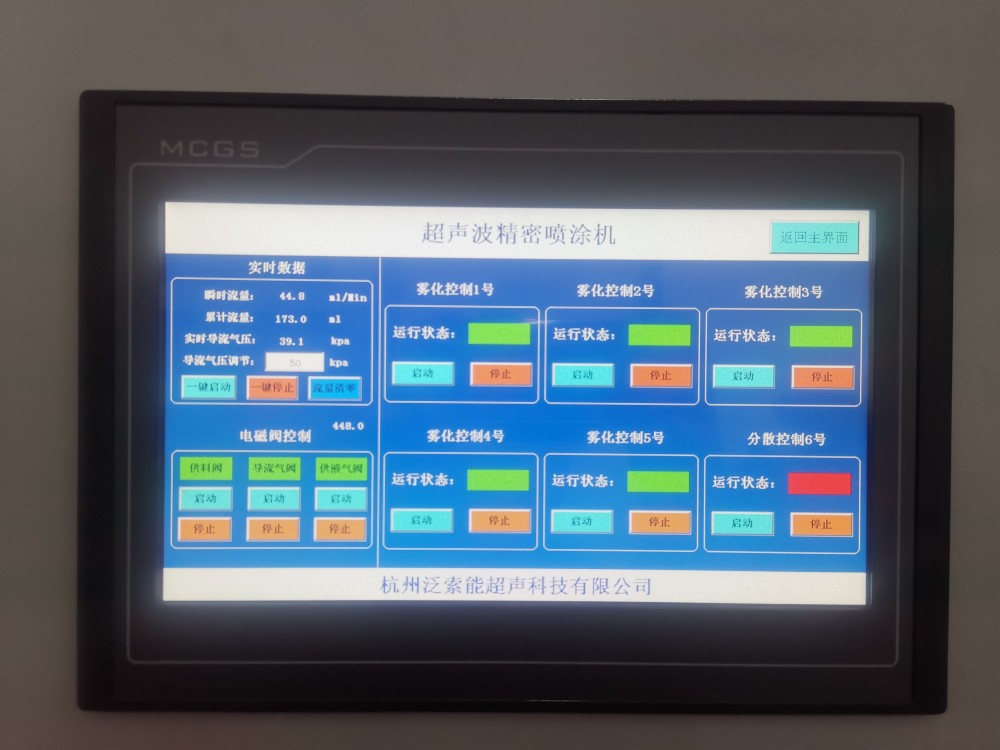

5. Operating System: Based on the Windows system, FUNSONIC independently developed a spraying control system, PLC control, and full-color touch screen

-

Optional Configuration

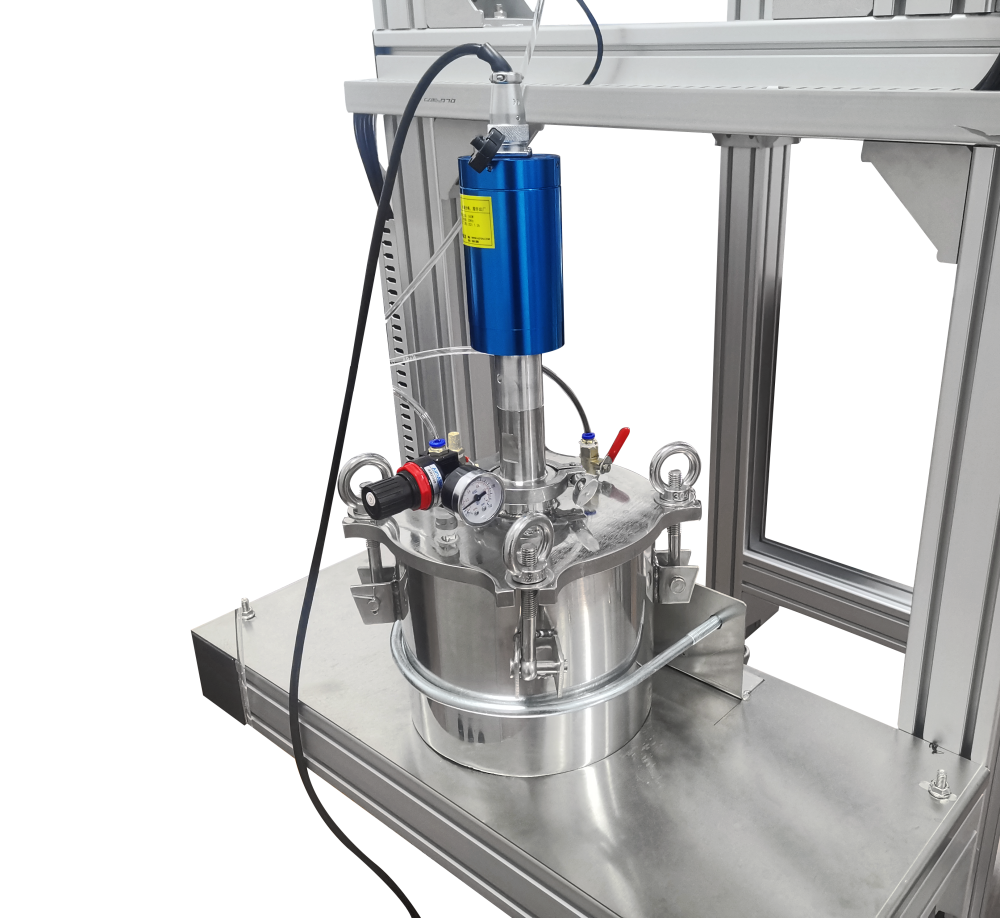

1. Ultrasonic dispersion pressure tank: 20Khz 2000w. Before atomization spraying, the solution is first subjected to ultrasonic dispersion treatment to avoid solid precipitation during the spraying process

2. Viscosity and Solid Content: Typically, the viscosity is ≤ 50cps, and the suspension requires a solid content of no more than 20-30%, depending on the properties of the liquid.

We can also customize other configurations according to your needs.

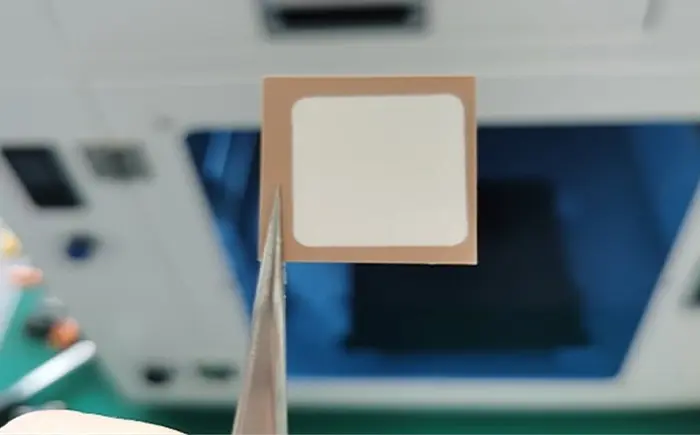

Product Application

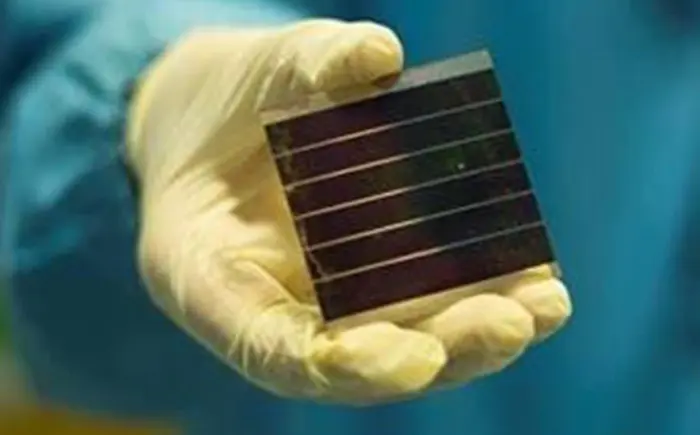

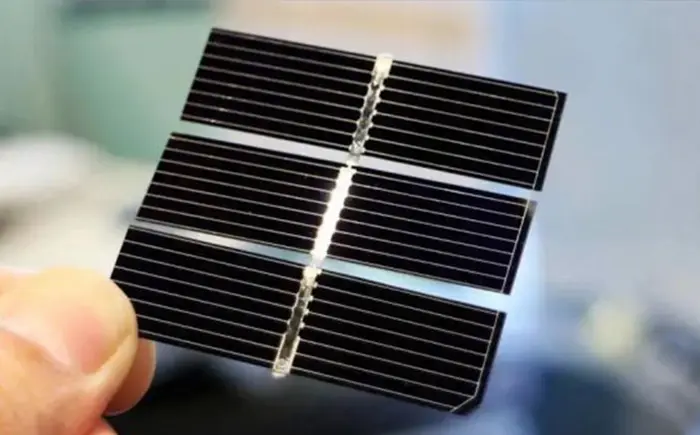

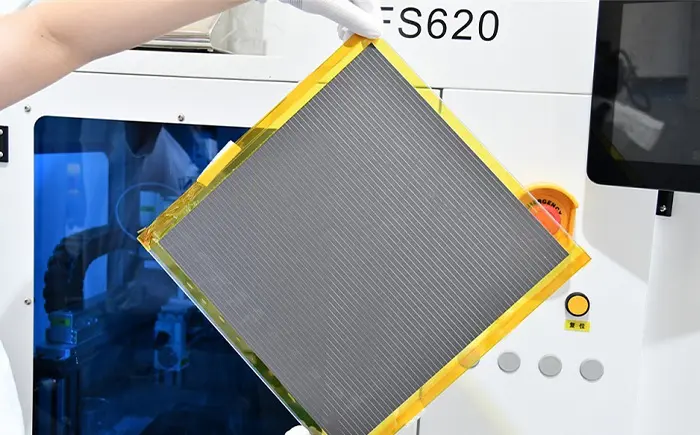

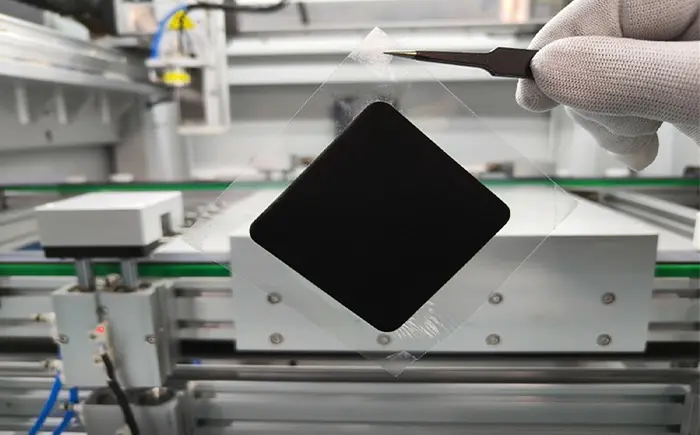

1. New energy: fuel cells, membrane electrodes, thin-film solar cells, proton exchange membranes, lithium battery separators, perovskite solar cells, solar photovoltaic silicon wafers, etc;

2. Medical: balloon catheter, blood collection tube injector, stent, biosensor, microfluidic chip, heart valve, antibacterial coating, etc;

3. Microelectronics and semiconductors: silicon carbide bonding, soldering flux, photoresist coating, conductive coating, hydrophilic and hydrophobic coating, conductive ink, PI, PET, etc;

4. Glass production: Glass coating, float glass, photovoltaic glass, photoluminescent film, transparent conductive, electrochromic, etc.

5. Nanotechnology: carbon nanotubes, polymer fibers, nano membranes, carbon nanotube membranes, MXenes、 Graphene composite materials, etc.