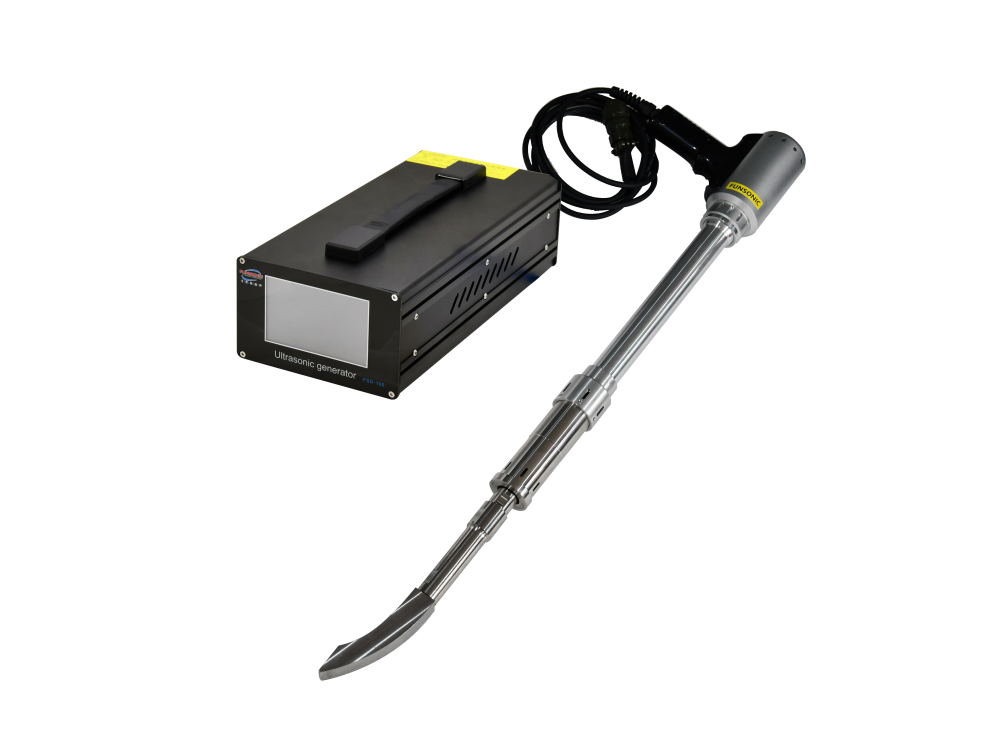

Ultrasonic Inner Circle Indium Coating Machine

Principle

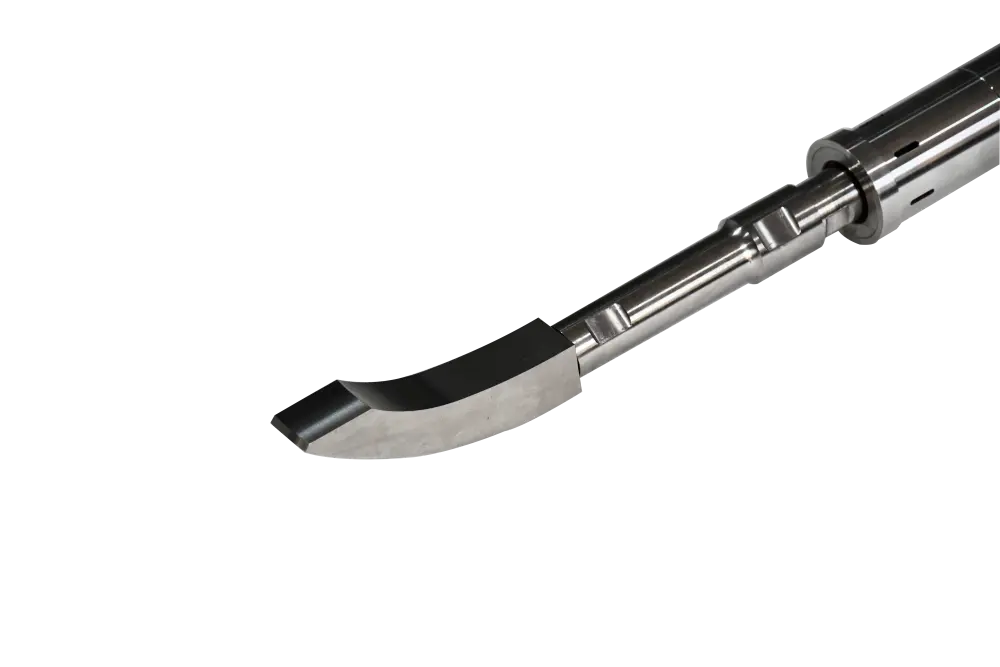

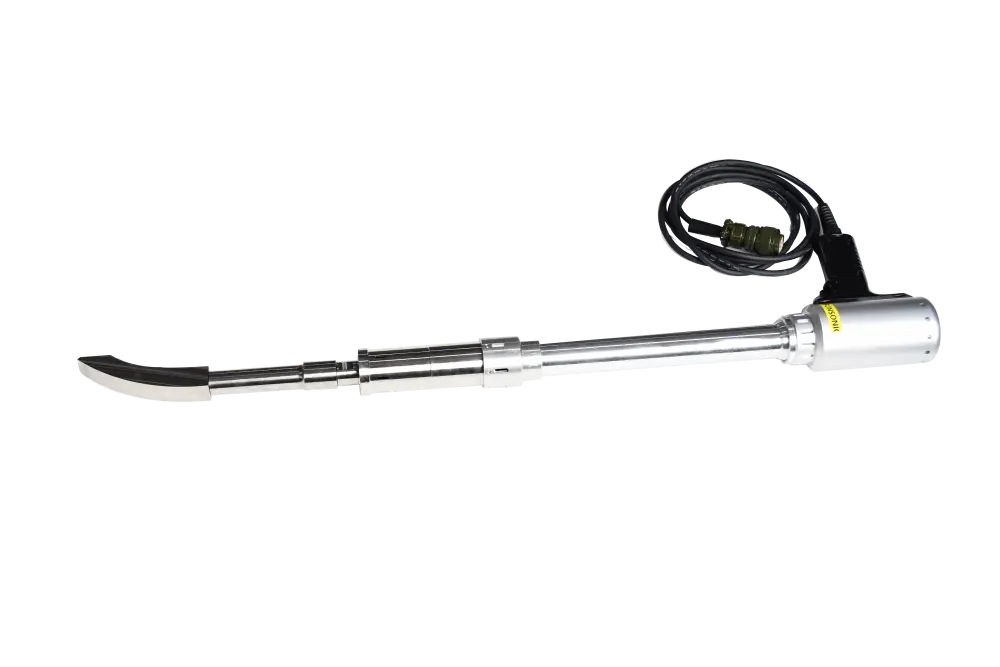

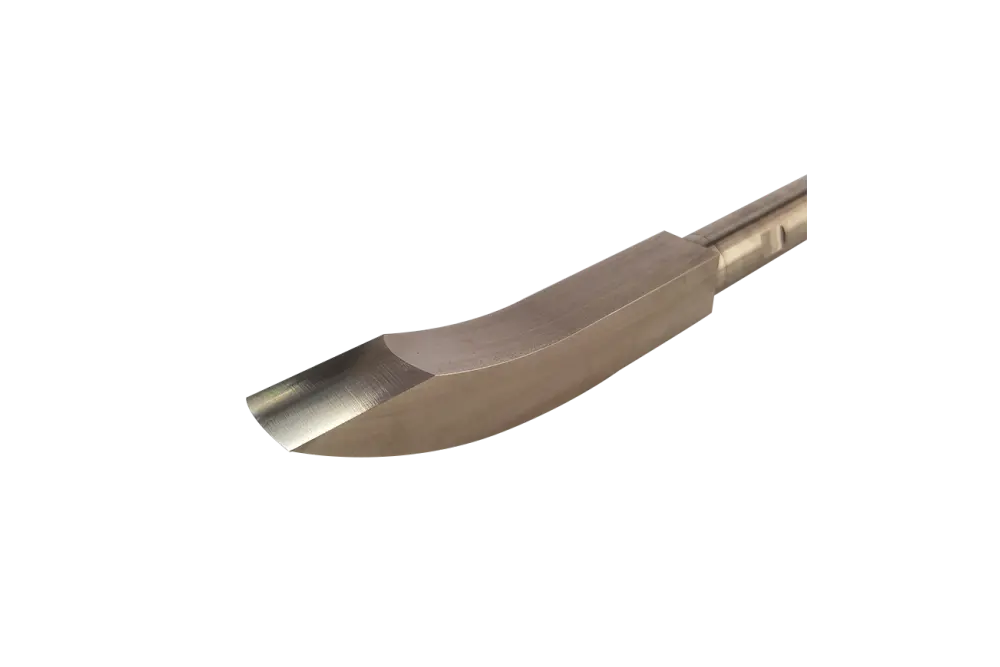

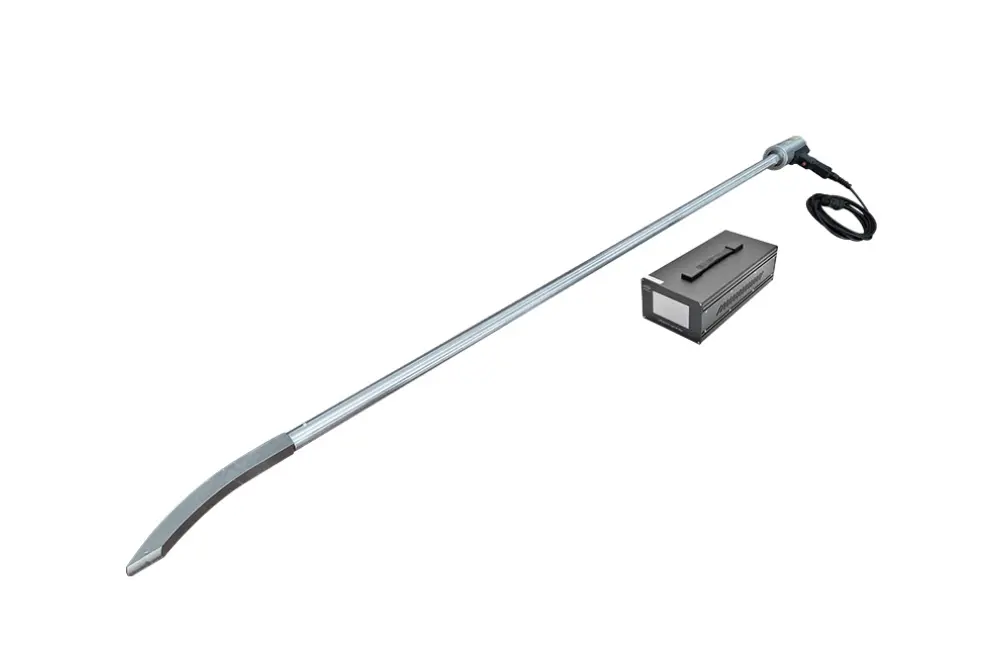

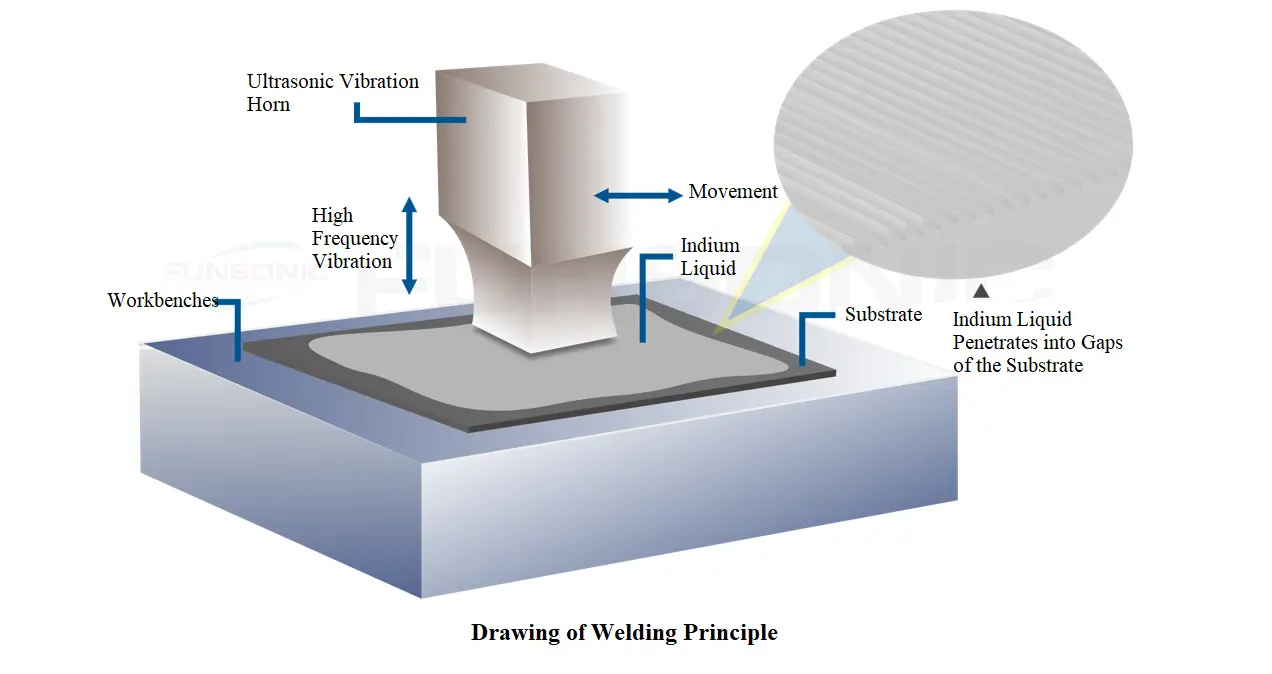

Ultrasonic indium coating uses the piezoelectric effect to convert electrical energy into high-frequency mechanical energy, which is transferred to liquid indium to generate standing waves. Liquid indium combines with the surface of the target material with the assistance of high-frequency vibration of ultrasound. When liquid indium is energized by ultrasonic vibration, it forms a high-density bonding surface with the surface of the target material. The isolation layer between the liquid indium and the target material disappears quickly with the support of ultrasonic work, thereby efficiently achieving the adhesion of the indium layer to the surface of the target material and improving the adhesion of the indium layer.

Advantages

◆The coating is firm and will not fall off.

◆ The coating is firm and will not fall off.

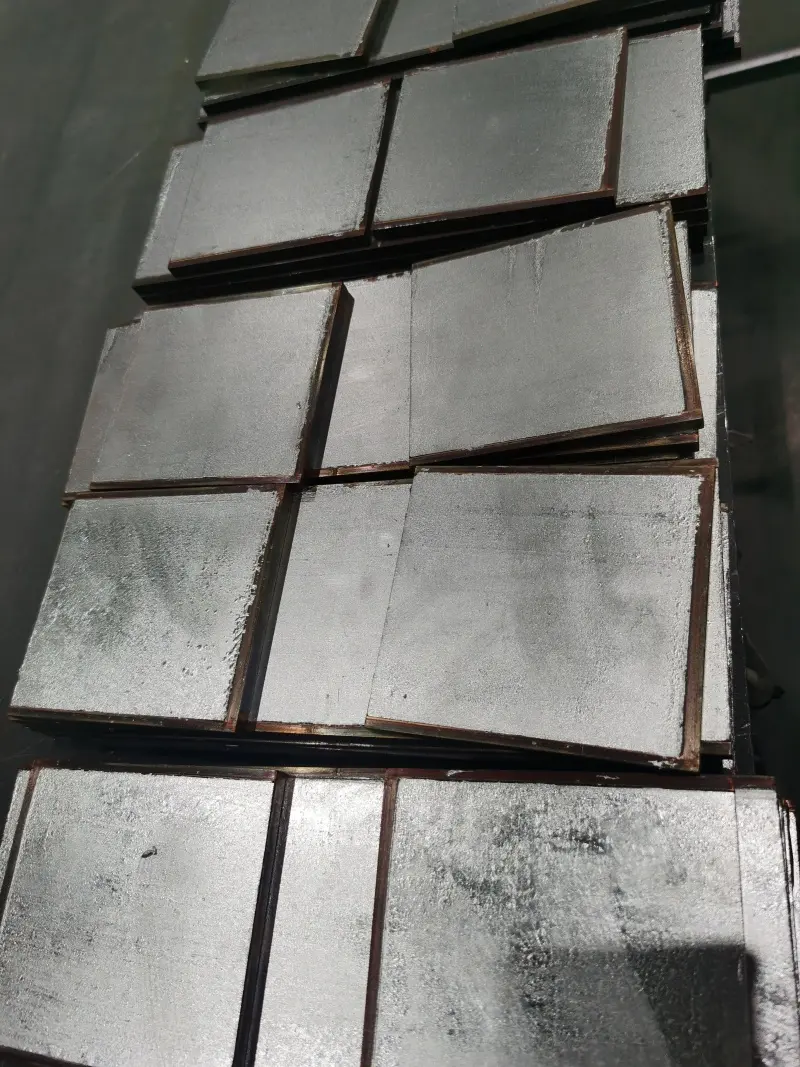

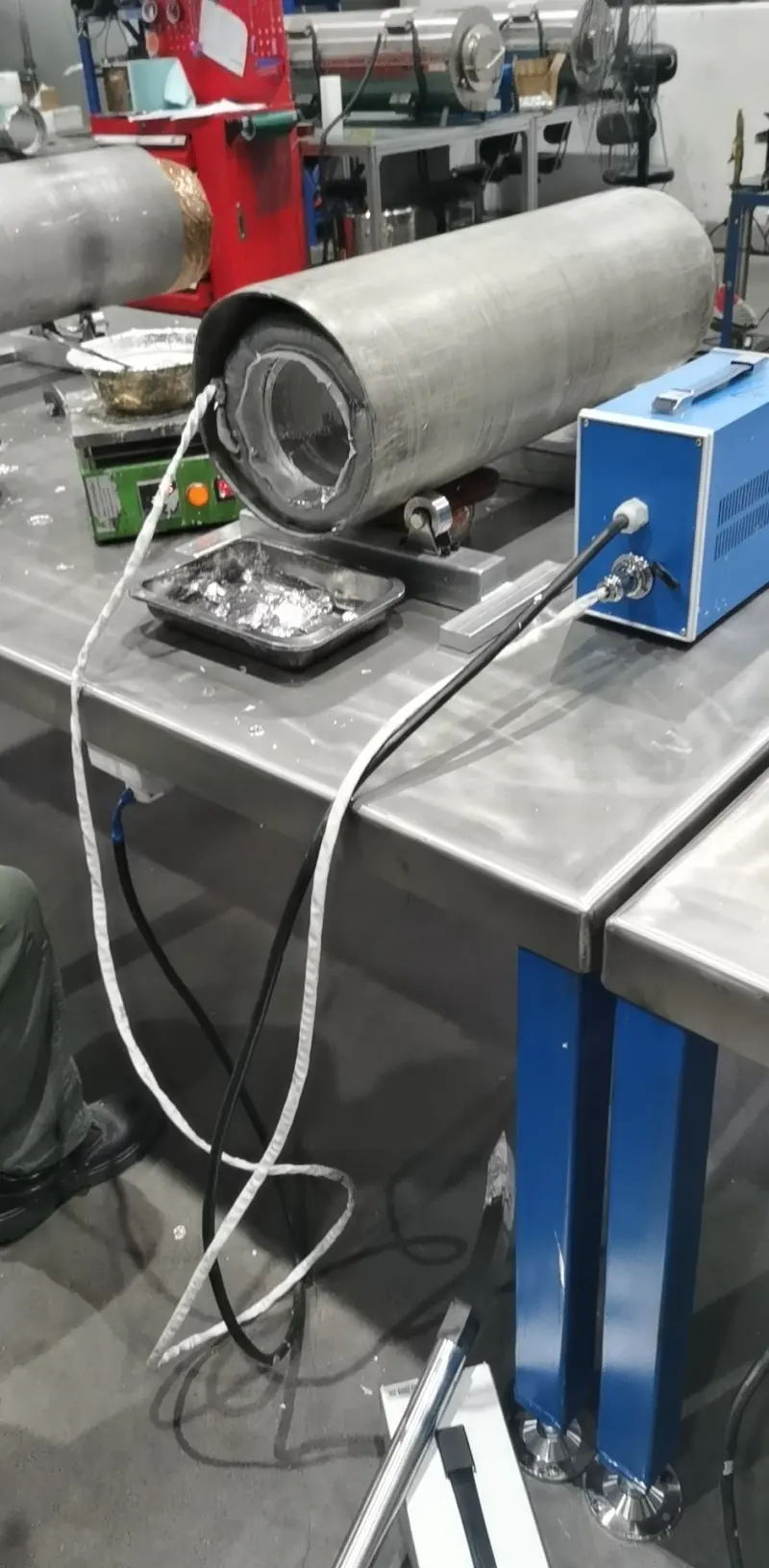

◆ Reduce production costs. By replacing expensive copper wire with aluminum wire, the production cost can be reduced by about 80%, saving indium metal, and the indium coating is within 0.02mm.

◆ Improve production efficiency. It only takes 15 minutes (2 vibrations) to coat a copper plate with an area of 1500*190mm. It only takes 1 minute (3 vibrations) to coat an ITO glass with an area of 50*50mm.

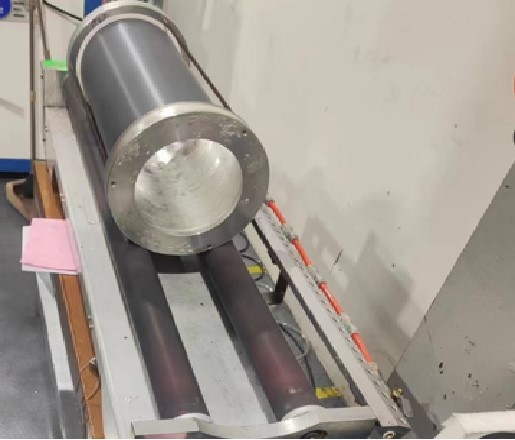

Demonstration

0102