Ultrasonic Impact Gun Machine

Principle

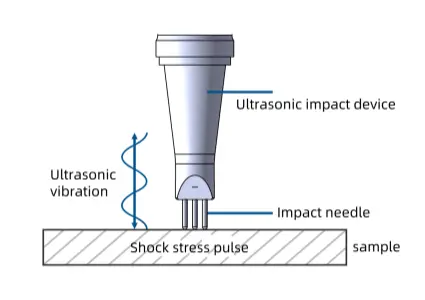

The high-power ultrasonic wave is used to drive the impact tool to impact the surface of the metal object at a frequency of more than 20,000 times per second. Due to the high frequency, high efficiency and high energy of the ultrasonic wave under focusing, the metal surface produces a large compressive plastic deformation. At the same time, the ultrasonic shock wave changes the original stress field, generates a certain value of compressive stress, and strengthens the ultrasonic impact part. The ultrasonic driving power supply is connected to the ultrasonic transducer set in the shell through a cable, and the vibration output end of the transducer is connected to the horn, and the end of the horn is equipped with an impact needle.

The ultrasonic driving power supply converts the mains electricity into a high-frequency and high-voltage alternating current and transmits it to the ultrasonic transducer. Then the ultrasonic transducer converts the input electrical energy into mechanical energy, that is, ultrasonic waves, which are manifested in the transducer making reciprocating telescopic motion in the longitudinal direction. The frequency of the telescopic motion is equal to the frequency of the AC current of the driving power supply, and the displacement of the telescopic motion is about ten microns. The function of the horn is to amplify the output amplitude of the transducer to more than 100 microns, and on the other hand, to apply impact force to the impact needle to push the impact needle forward at high speed. After the impact needle impacts the workpiece, the energy is transmitted to the weld to eliminate the internal stress. The impact head rebounds after being reacted by the workpiece, and after hitting the high-frequency vibrating horn, it is excited again and hits the weld at high speed again. This process is repeated many times to complete the impact operation.

Advantages

◆ Portable and efficient: Compared with traditional heat treatment, it is flexible to operate and suitable for on-site operations.

◆Energy-saving and environmentally friendly: No pollution, low energy consumption, in line with modern industrial environmental protection requirements.

◆Intelligent control: Some new equipment is equipped with LCD display and automatic adjustment of impact parameters.

Demonstration

0102