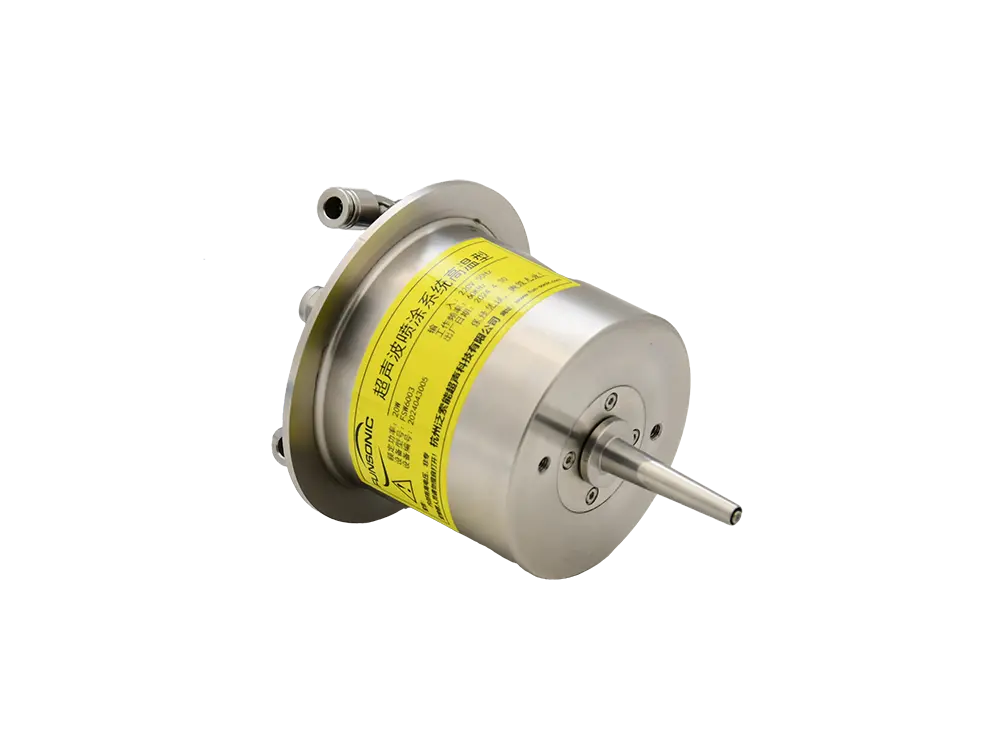

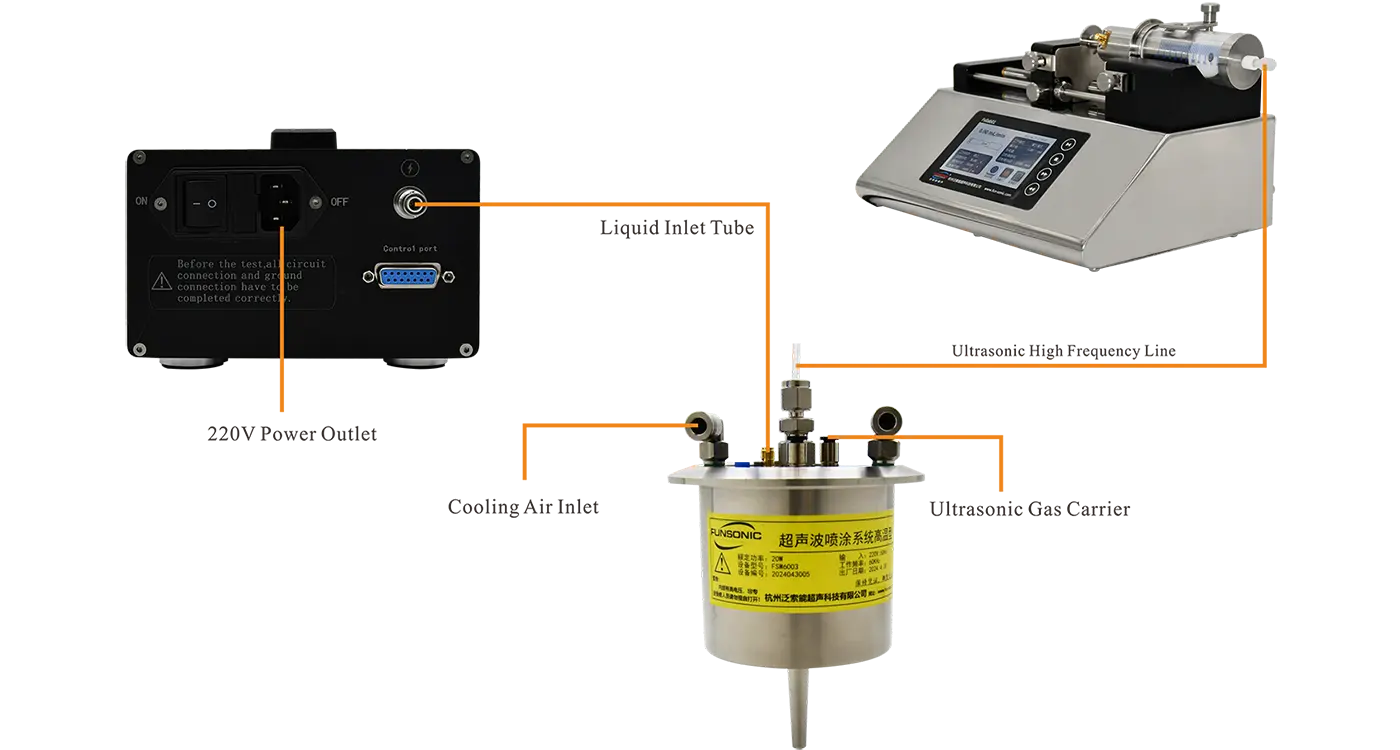

Ultrasonic High Temperature Spray Nozzle

Application

1.Metallurgical industry:Application scenarios: Atomization cooling and humidification in high-temperature furnaces, molten metal pools, and other environments

Advantages: High temperature resistance, improved equipment stability and production efficiency

2. Chemical industry:Application scenario: reactant/medium spray of high-temperature reaction kettle, distillation tower, etc

Advantages: Corrosion resistance, helps improve reaction control and product quality

3. Glass industry:Application scenario: atomization cooling in high-temperature areas such as glass furnaces and annealing furnaces

Advantages: Good high-temperature stability, beneficial for optimizing glass manufacturing processes

4. Electronics industry:Application scenario: Cleaning and disinfection in semiconductor equipment and electronic component manufacturing

Advantages: Low noise, no environmental pollution, helps improve cleanliness 5. Aerospace field:Application scenario: engine spray cooling, cabin environment disinfection, etc

Advantages: High temperature resistance, improved equipment stability and production efficiency

2. Chemical industry:Application scenario: reactant/medium spray of high-temperature reaction kettle, distillation tower, etc

Advantages: Corrosion resistance, helps improve reaction control and product quality

3. Glass industry:Application scenario: atomization cooling in high-temperature areas such as glass furnaces and annealing furnaces

Advantages: Good high-temperature stability, beneficial for optimizing glass manufacturing processes

4. Electronics industry:Application scenario: Cleaning and disinfection in semiconductor equipment and electronic component manufacturing

Advantages: Low noise, no environmental pollution, helps improve cleanliness 5. Aerospace field:Application scenario: engine spray cooling, cabin environment disinfection, etc

0102030405

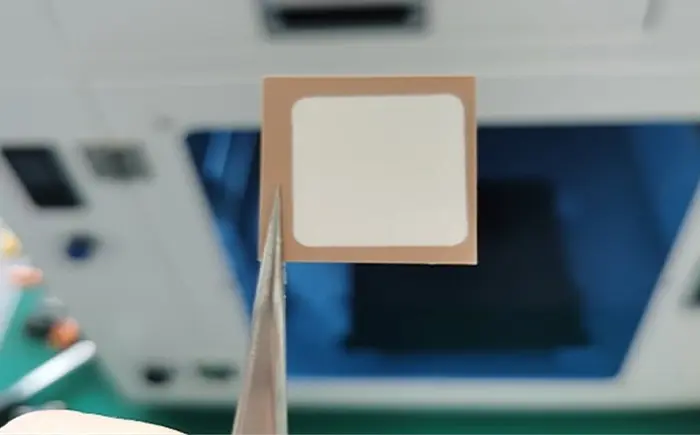

Demonstration

0102