Ultrasonic Fume Hood Coating System FS630

Advantage

Product Configuration

-

Conventional Arrangement

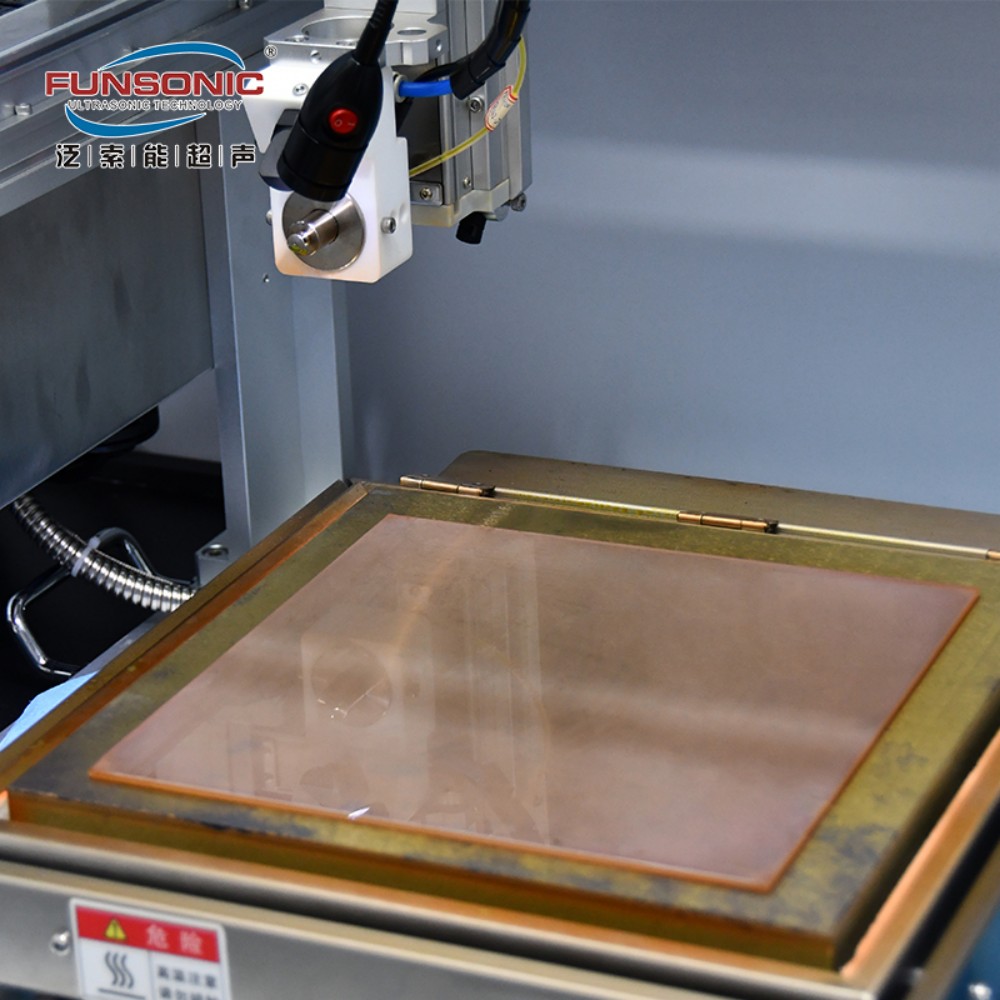

1. Ultrasonic atomizing nozzle: FUNSONIC has developed and produced dozens of ultrasonic nozzles, which can be suitable for various working conditions and film thickness requirements.

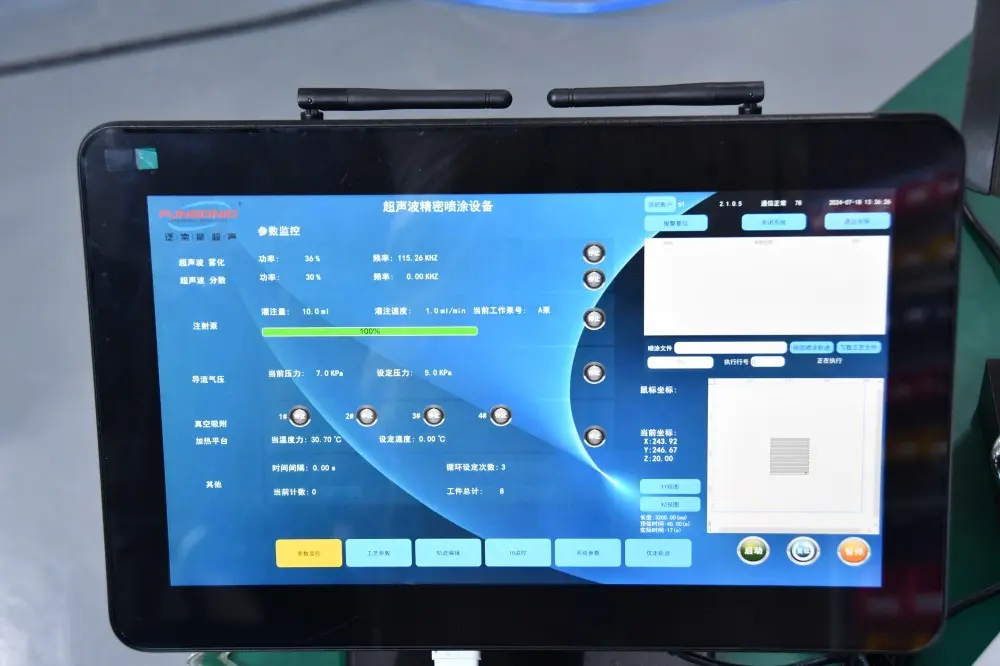

2. Ultrasonic CNC power supply: Fully CNC precision power supply, fully intelligent frequency following, frequency tracking, stable performance

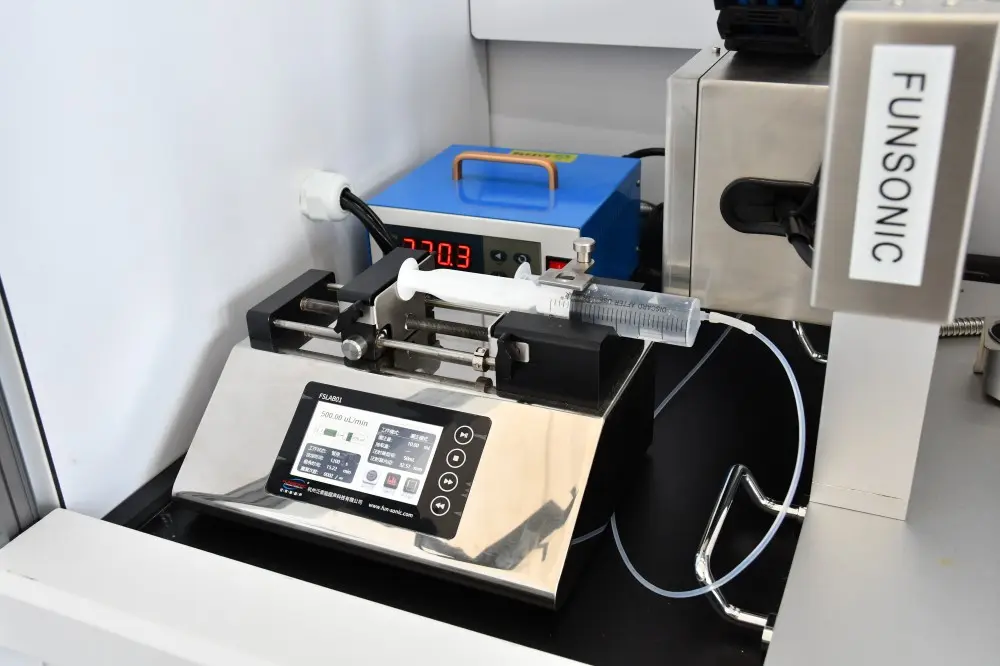

3. Liquid supply equipment: precision injection pump+biological grade sampler, liquid supply accuracy of 0.1 μ L/min

4. Motion system: XYZ three-axis imported servo motor+precision screw module

6. Top exhaust system: Excess atomized exhaust gas and high-temperature gases can be discharged through the exhaust system

-

Optional Configuration

1. Ultrasonic dispersion supply system: The ultrasonic dispersion system can achieve high-performance cavitation treatment, effectively mixing, dispersing, and crushing samples such as blood, saliva, and suspended particles.

2. Heating and drying platform: aluminum alloy plate, ceramic microporous or high-temperature stainless steel, 300 * 300mm (size can be customized), temperature controller controls temperature ± 1 ℃

3. Vacuum adsorption platform: The inner cavity is evacuated to a negative pressure state, allowing the small circular holes on the surface to adsorb flat thin film products.

4.Laser positioning device: Use laser to quickly align the solution spraying position.

We can also customize other configurations according to your needs.