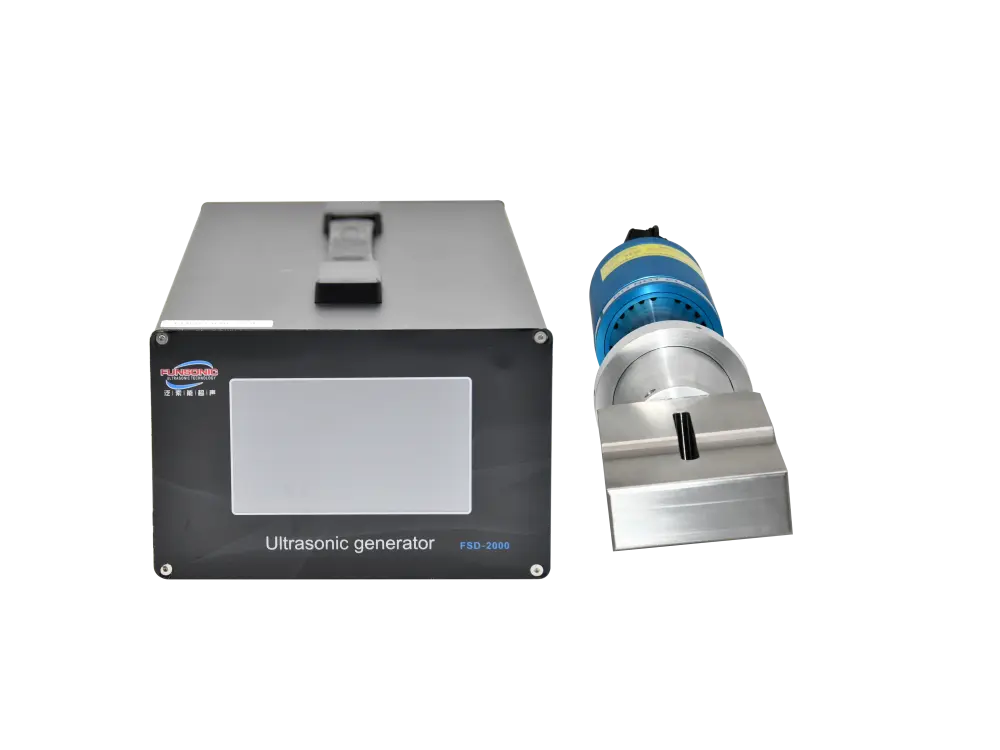

Ultrasonic Flat Indium Coating Machine

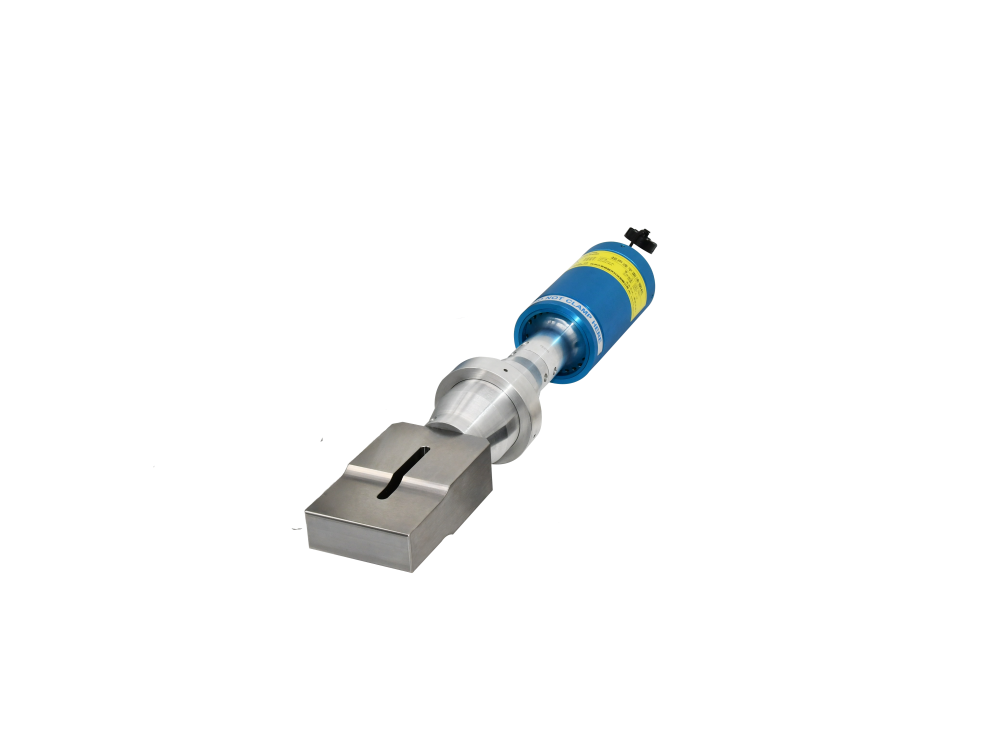

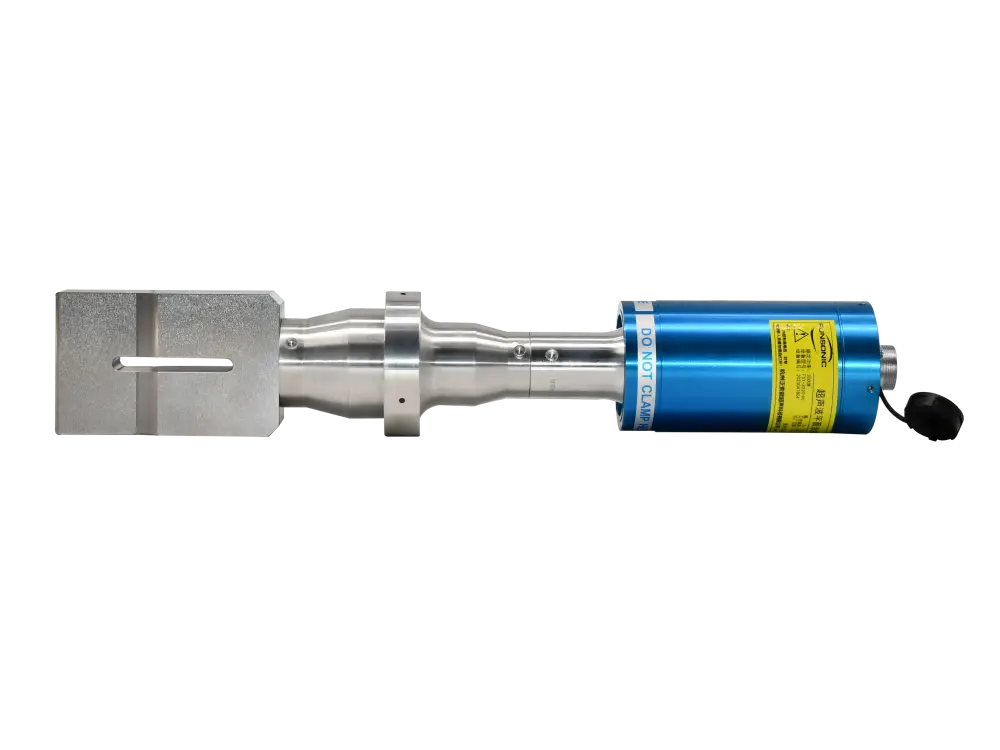

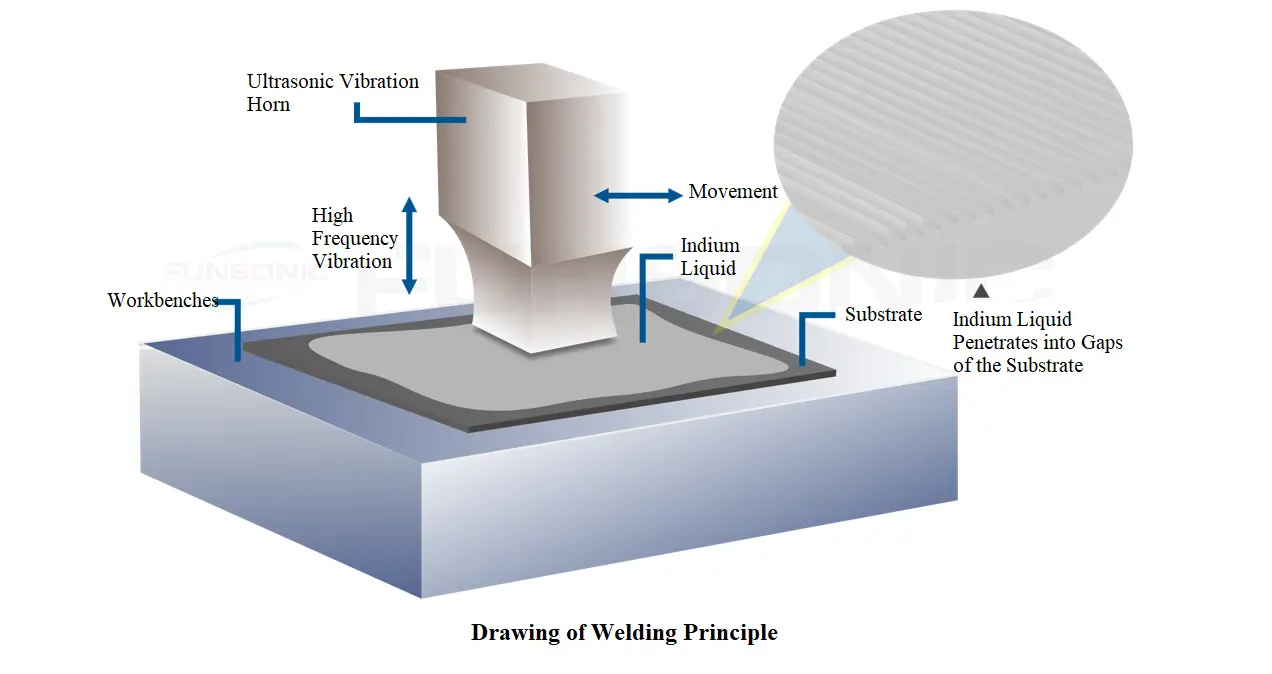

Principle

Ultrasonic vibration causes high-frequency micro-friction between the tool head and the indium metal or substrate, and the local temperature rises (usually lower than the melting point of indium 156°C), which softens the indium but does not completely melt, enhancing fluidity. The vibration energy destroys the oxide film between the indium layer and the substrate, and expels microbubbles on the interface to achieve a non-porous bond. Under the action of pressure and vibration, indium atoms and substrate atoms diffuse with each other to form a metallurgical bond without the need for flux. The welding head moves along a planar path to ensure that the thickness of the indium layer is uniform (controllable within 0.01-0.05mm).

Advantages

Cold welding technology: Indium does not need to be completely melted to avoid high temperature thermal deformation.

◆ No chemical additives: completely dependent on physical vibration, no pollution.

◆ High coating quality: The indium layer is uniform without blind spots or ripples, has strong adhesion and is not easy to fall off.

◆ Compatible with heterogeneous materials: Can weld copper-glass, aluminum-ceramic and other traditionally difficult materials.

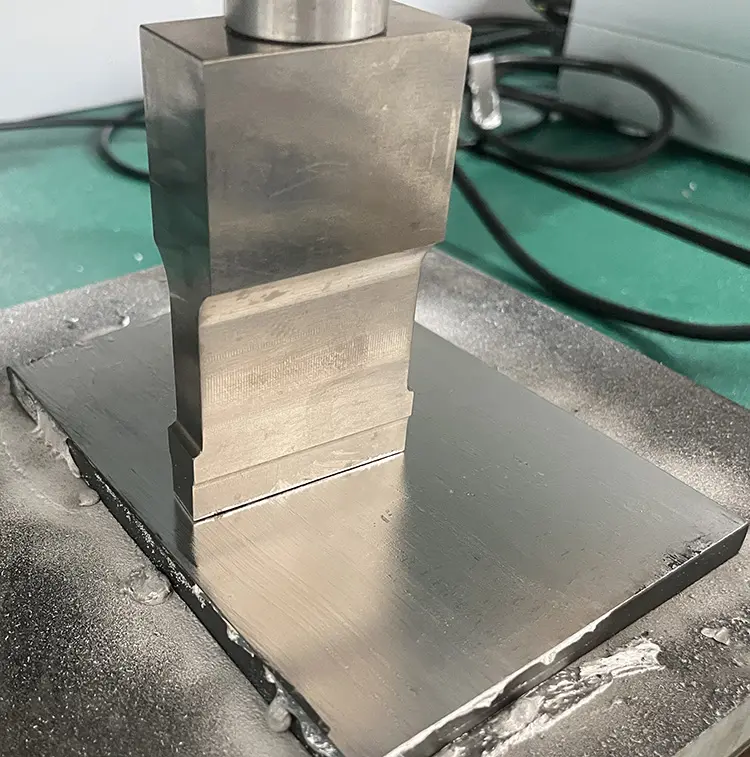

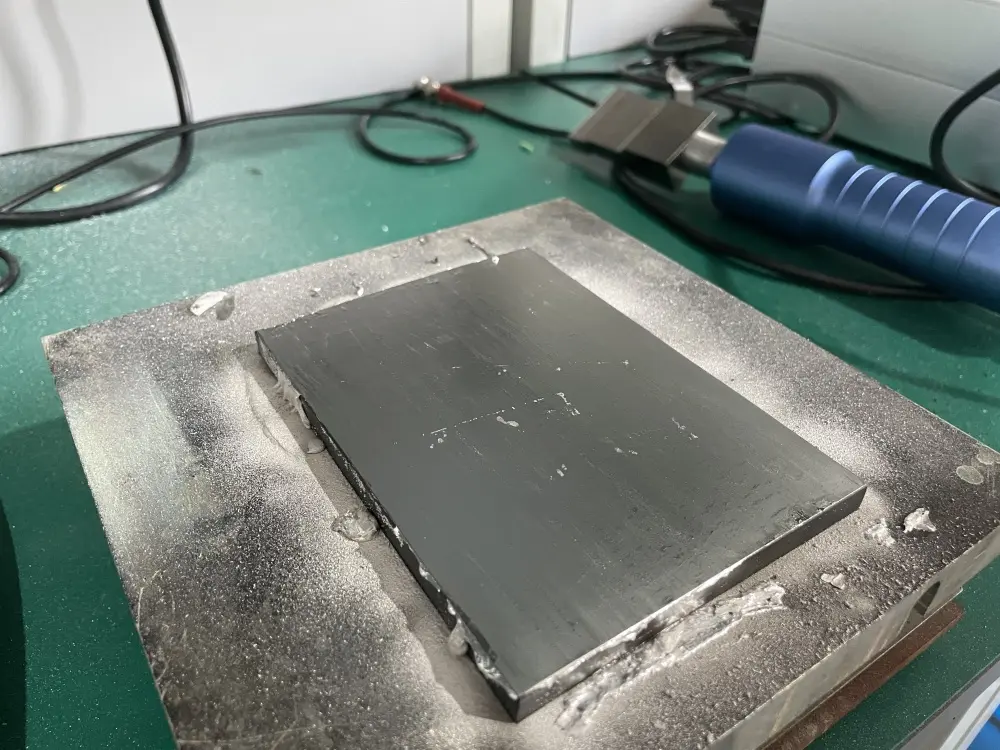

Demonstration

0102