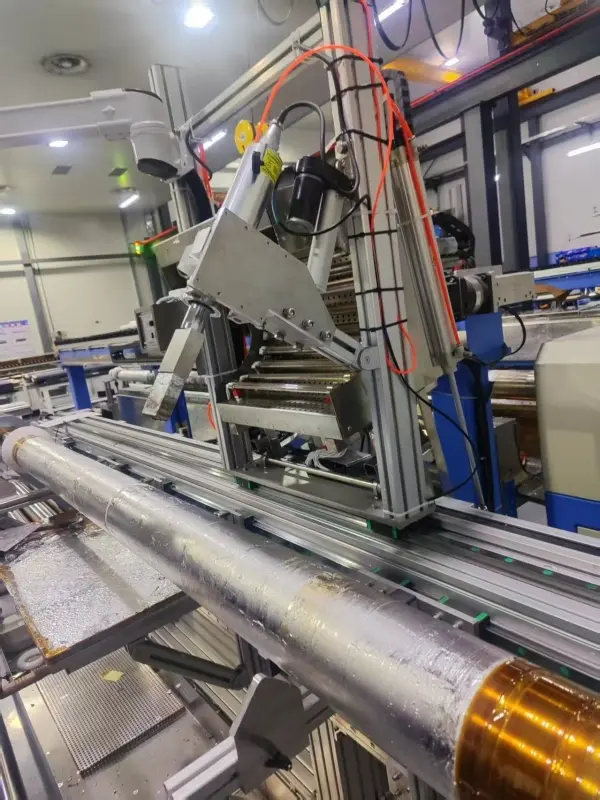

Ultrasonic cylindrical indium coating machine

Advantages

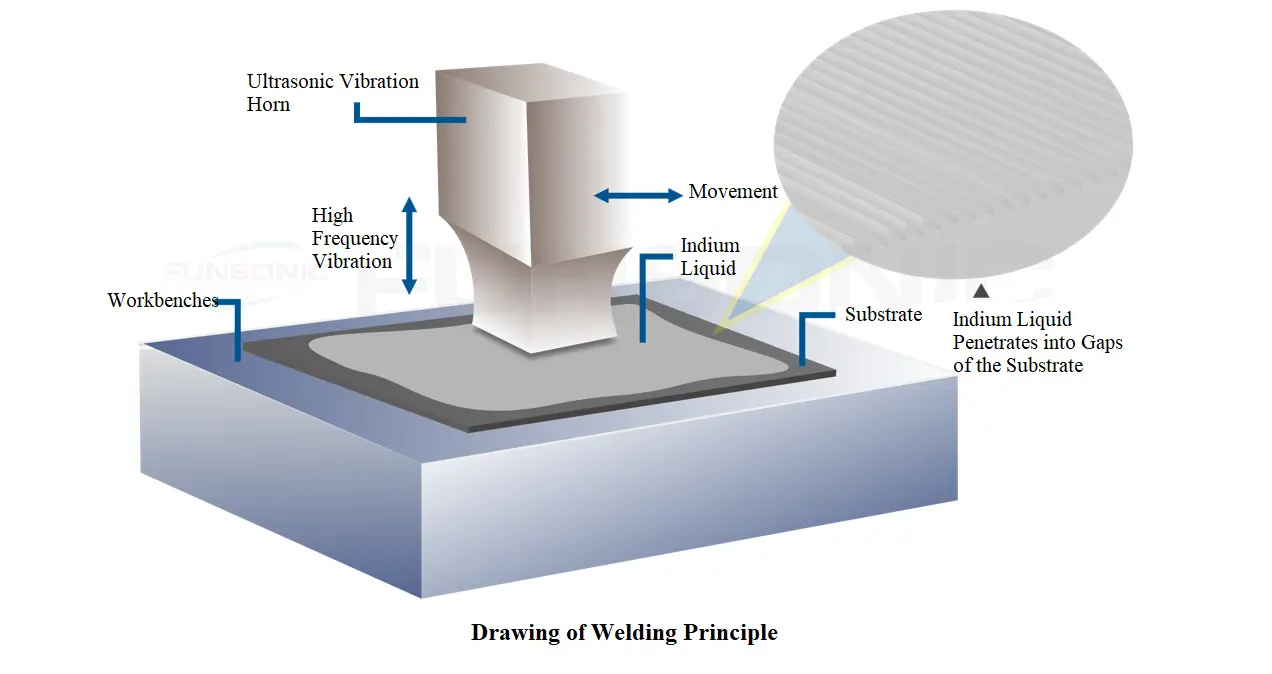

◆ Flux-free environmentally pleasant welding: Avoid hazardous gases and wastewater produced by means of regular soldering flux, and no extra environmental safety amenities are required.

◆ High coating quality: The indium layer is uniform barring blind spots or ripples, has robust adhesion and is now not effortless to fall off. It is appropriate for a range of substances such as copper, aluminum, glass, ceramics, etc., and helps welding of heterogeneous substances such as aluminum-copper.

◆ High effectivity and electricity saving: It solely takes 15 minutes (2 vibrations) to coat a copper plate with an region of 1500×190mm, which is an awful lot extra environment friendly than guide work. It saves indium steel utilization and reduces manufacturing charges via about 80%.

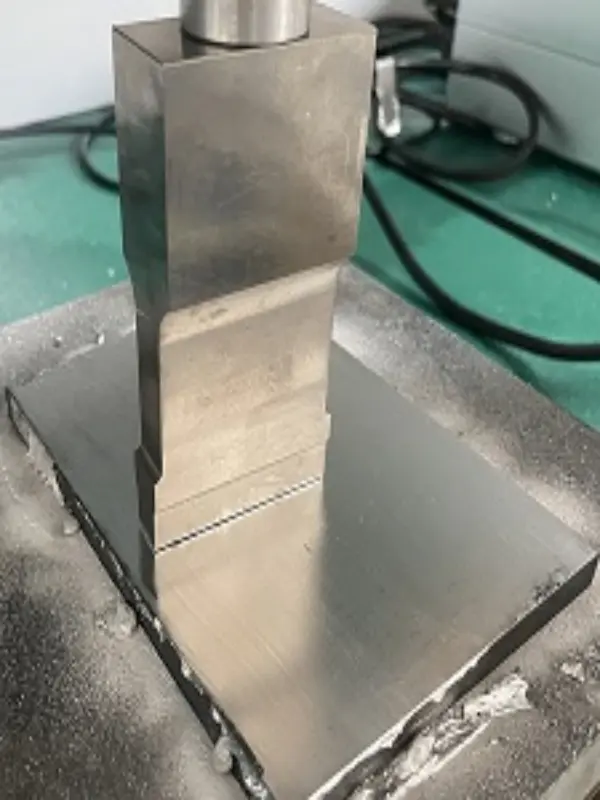

◆ Wide method adaptability: The form of the welding head (round head, rectangular head, etc.) can be custom-made to meet the desires of special goal materials. Support excessive temperature surroundings (working temperature can attain 350℃), and cooperate with the heating platform to enhance the bonding strength.