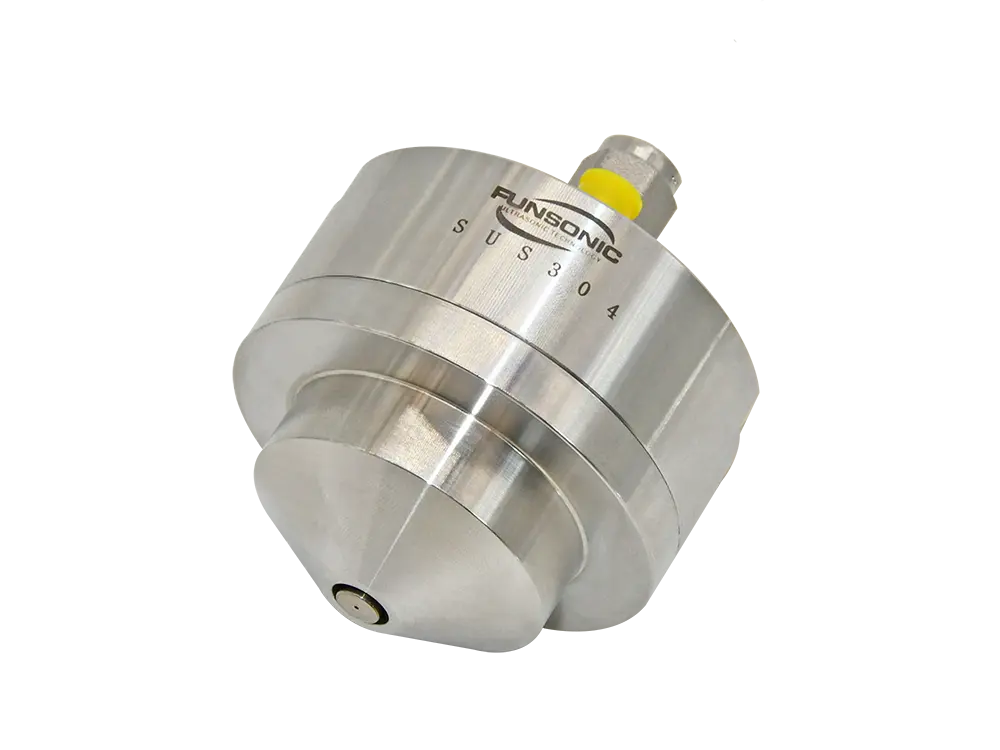

Ultrasonic Conemist Spray Nozzle

Application

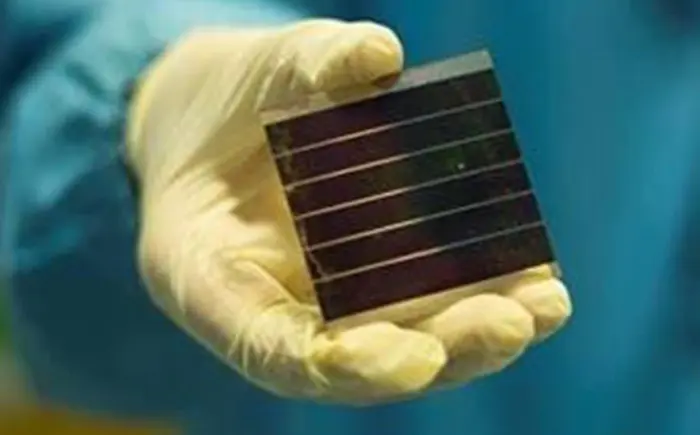

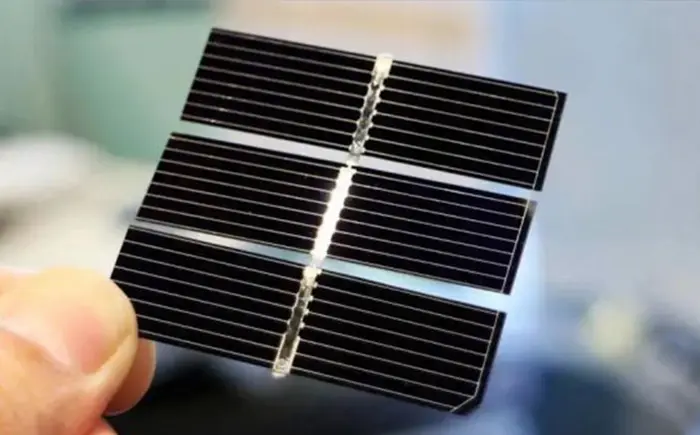

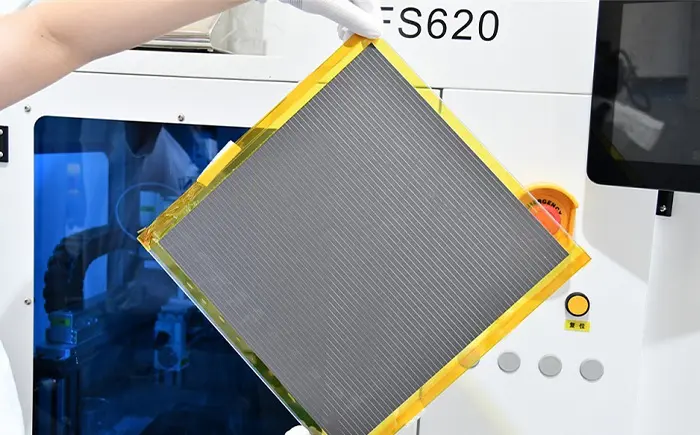

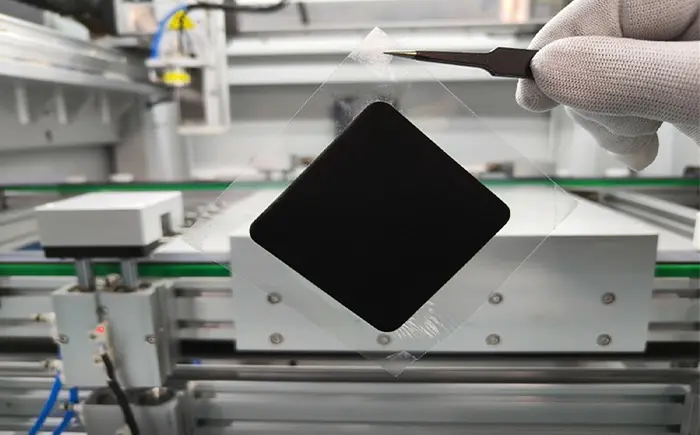

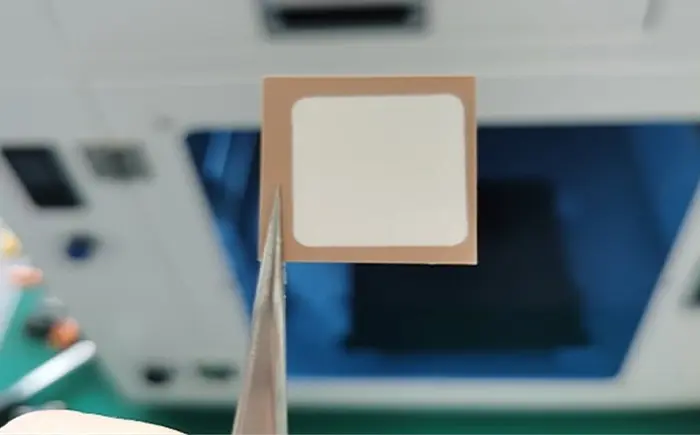

The vortex ultrasonic nozzles use an air hood to create a wide "vortex-like" dispersion, ideal for coating flat objects such as PEM fuel cells and solar cells. Reciprocating vortex nozzles are preferred. Simple XY stages can be used.

0102030405

Demonstration

0102