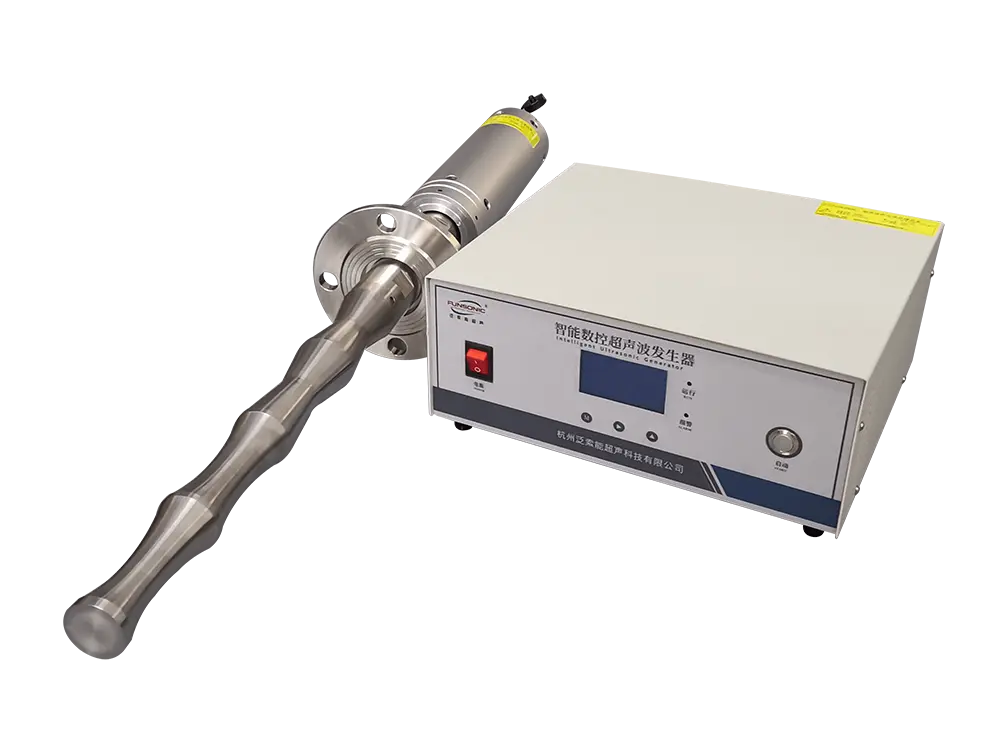

Standard Pilot Machine Ultrasonic Sonochemical Equipment

5. Nanomaterials: In the preparation process of nanomaterials, ultrasonic sonochemical equipment can promote the synthesis and dispersion of particles, and improve the performance of materials.

6. Environmental Protection: In the field of environmental protection, ultrasonic sonochemical equipment is used for water pollution treatment, air purification, etc., which can effectively degrade pollutants.

7. Petroleum: Ultrasonic sonochemical equipment is used in oil extraction and processing to improve the recovery rate and separation efficiency of oil wells.

8. Textile leather: In the textile and leather industry, ultrasonic sonochemical equipment is used for dyeing, degreasing and other processes to improve treatment efficiency and product quality.