What are the advantages of ultrasonic sonochemistry in extraction applications

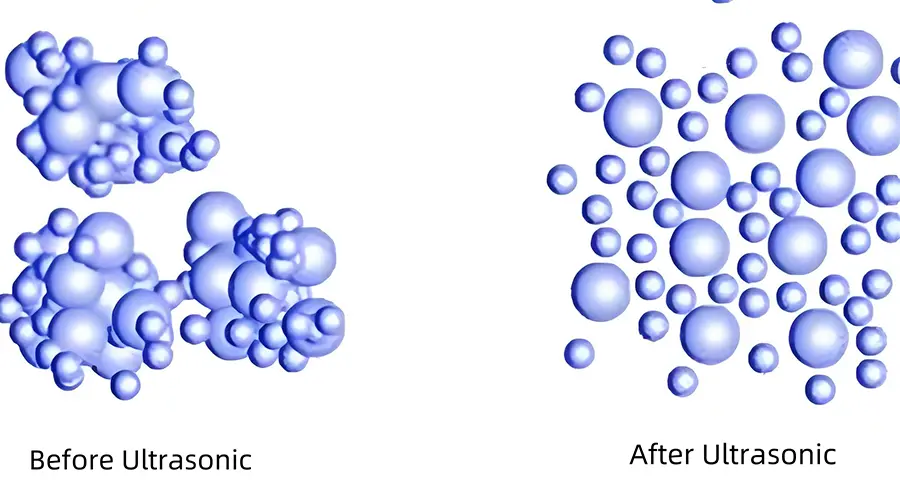

As an efficient and environmentally friendly physical and chemical method, ultrasonic sonochemistry technology has shown significant application potential in the field of nanomaterial dispersion and extraction in recent years. The special effects of cavitation effect, microjet and shear force produced by high-power ultrasound in liquids can effectively solve the problem of nanomaterial agglomeration and greatly improve the efficiency and uniformity of the biological extraction process. .

The following are the core advantages of ultrasonic extraction:

1. Ultrasonic extraction has significant efficiency

Traditional extraction methods such as stirring and heating usually take several hours or even longer to extract special components in biological materials. Ultrasonic intervention and assisted extraction can quickly destroy cell walls or molecular structures by using its special cavitation effect, which will greatly shorten the operation time and extract more components in depth. For example, the extraction of flavonoid components in traditional Chinese medicine takes 6-8 hours by traditional methods, but can be completed within one hour by ultrasonic method, and the extraction efficiency is significantly improved.

2. Ultrasonic extraction can reduce the amount of solvent used

Traditional processes rely on a large amount of organic solvents (such as methanol and ethanol) to achieve the purpose of decomposition and leaching, while ultrasonic technology can reduce the amount of solvent used by 30%-60% by enhancing the permeability of solvents, reducing environmental pollution and costs. For example, in the food industry, the ultrasonic method only requires 50% ethanol solution to achieve the same efficiency as the traditional process for lycopene extraction.

3. Achieve low temperature and excessive efficiency, defend heat-sensitive ingredients

The nearby excessive temperature generated through ultrasonic cavitation solely lasts for microseconds, and the typical response temperature is low (usually <50°C), warding off excessive temperature injury to lively components (such as nutritional vitamins and enzymes). For example: in the extraction of blueberry anthocyanins, the ordinary warmness reflux technique reasons 20% of the elements to degrade, whilst the ultrasonic approach can attain a retention charge of greater than 95%.

4.Common application areas of ultrasonic extraction

Extraction of energetic elements in common Chinese medicine: In the extraction of standard Chinese medicine, ultrasonic extraction science can shortly and correctly extract the energetic elements in typical Chinese remedy via the cavitation effect, which has the blessings of strength saving and environmental protection.

Environmental science: In the discipline of environmental science, ultrasonic extraction technological know-how is used for factor evaluation of environmental samples, which can improve the accuracy and effectivity of analysis.

Food processing: In meals processing, ultrasonic extraction science is extensively used to extract components such as spices and pigments. In addition, excessive value-added components can additionally be extracted from rice bran, wheat bran, soybeans, corn germs, etc.

Biological industry: Ultrasonic extraction technological know-how is additionally broadly used in the organic industry, such as the extraction of energetic components in plants. For example, ultrasonic circulation extraction technology has the characteristics of short time and simple operation in pollen cell wall breaking technology, which greatly reduces production costs.

5. Conclusion

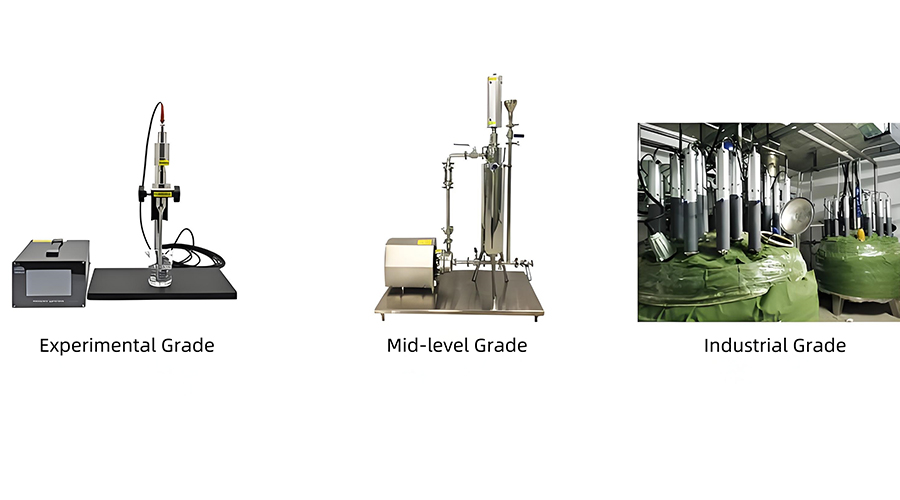

Ultrasonic sonochemistry technology achieves efficient and green extraction through physical action, and has irreplaceable advantages in shortening time, reducing costs, and improving purity. This technology will further replace traditional methods in the fields of pharmaceuticals, food, environmental protection, etc., and promote industrial upgrading. FUNSONIC provides equipment in various processing application modes from experimental level, pilot level, and industrial level according to different needs of customers. Provide free experiments for customers in the early stage; formulate corresponding product solutions based on user actual conditions.