Ultrasonic Spray Granulation

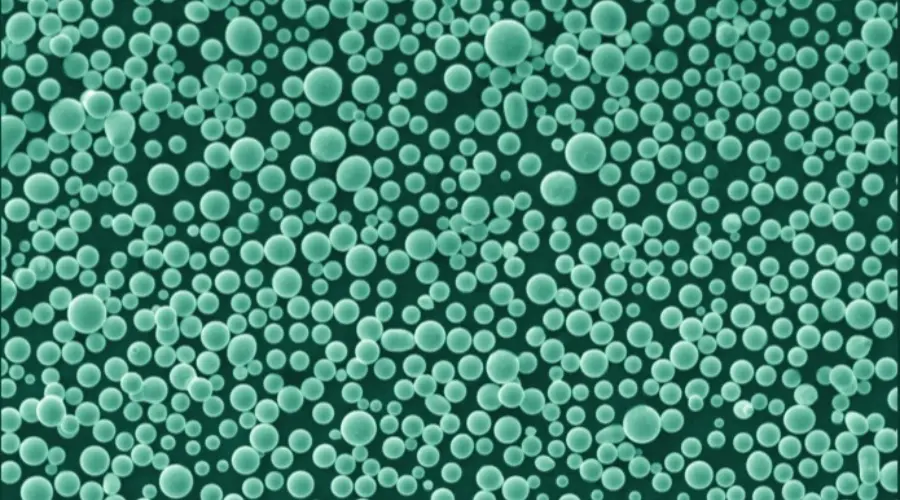

Ultrasonic spray granulation is a technological know-how that makes use of ultrasonic strength to atomize liquid into tiny droplets and structure particles thru a drying or curing process. This science is broadly used in the fields of pharmaceuticals, chemicals, substances science, meals and agriculture, and can produce micron or submicron particles with uniform particle measurement and controllable morphology. The following are the key technical elements and purposes of ultrasonic spray granulation:

1. Technical principle

The core of ultrasonic spray granulation is to wreck liquid into best droplets thrug high-frequency vibration (usually 15kHz–120kHz):

Ultrasonic atomization: Ultrasonic atomization: The ultrasonic transducer converts electrical strength into mechanical vibration, which is transmitted to the atomizing head thru the amplitude transformer, so that the liquid types uniform atomized droplets at the nozzle.

Drying or curing: The atomized droplets are in contact with warm air (spray drying) or enter a cooling/reaction surroundings to shape strong particles.

Particle measurement control: The particle measurement (usually 1–100μm) can be exactly managed through adjusting parameters such as ultrasonic frequency, power, and liquid go with the flow rate.

2. Main equipment components

Typical ultrasonic spray granulation structures include:

Ultrasonic generator: gives high-frequency electrical indicators (such as 50kHz, 100kHz, etc.).

Atomizing nozzle: Made of titanium alloy or stainless steel, excessive temperature resistant (up to 500℃), appropriate for metallic melts or corrosive liquids.

Injection pump/delivery system: controls liquid feed charge (such as 0.001–30 mL/min).

Drying tower/collection device: such as centrifugal spray tower, cyclone separator, etc., used for particle drying and classification.o 500℃), appropriate for metallic melts or corrosive liquids.

3. Technical advantages

Particle uniformity: Compared with ordinary spray (centrifugal or stress type), ultrasonic atomization droplets are finer and narrowly distributed, appropriate for the coaching of high-precision tablets or catalysts.

No clogging, low strength consumption: no mechanical transferring parts, appropriate for beverages with excessive viscosity or containing stable suspensions.

Versatility: can put together microcapsules (such as immiscible liquids), steel powders, drug particles, etc.

Environmental protection and energy saving: some systems are combined with vacuum degassing to reduce the impact of bubble cavitation and improve particle strength.

4. Typical application areas

Pharmaceuticals: Preparation of inhaled tablets (such as 5μm dry powder particles).

Chemical catalysts: Improve the particle dimension distribution and put on resistance of fluidized mattress catalysts.

Material science: Preparation of ultrafine steel or ceramic powders (such as graphene, nano coatings).

Agriculture: Granulation of compound fertilizers to enhance mixing effectivity and particle strength.

Ultrasonic spray granulation technology has become an important method of modern powder engineering with its high precision, low energy consumption and wide applicability. Future development directions may include higher frequency atomization (such as MHz level), intelligent parameter control, and integrated applications combining emerging technologies such as 3D printing. For specific equipment selection or process optimization, please refer to the manufacturer's technical parameters or academic patents.