Ultrasonic Spray Coating Photoresist Technology

Photoresist is a crucial material in the manufacturing of modern chips, photovoltaic panels, and integrated circuit boards. With the increasing global dependence on electronic semiconductor materials, higher requirements have been put forward in the preparation of nanoscale circuit boards, and the quality of photoresist coatings plays a key role.

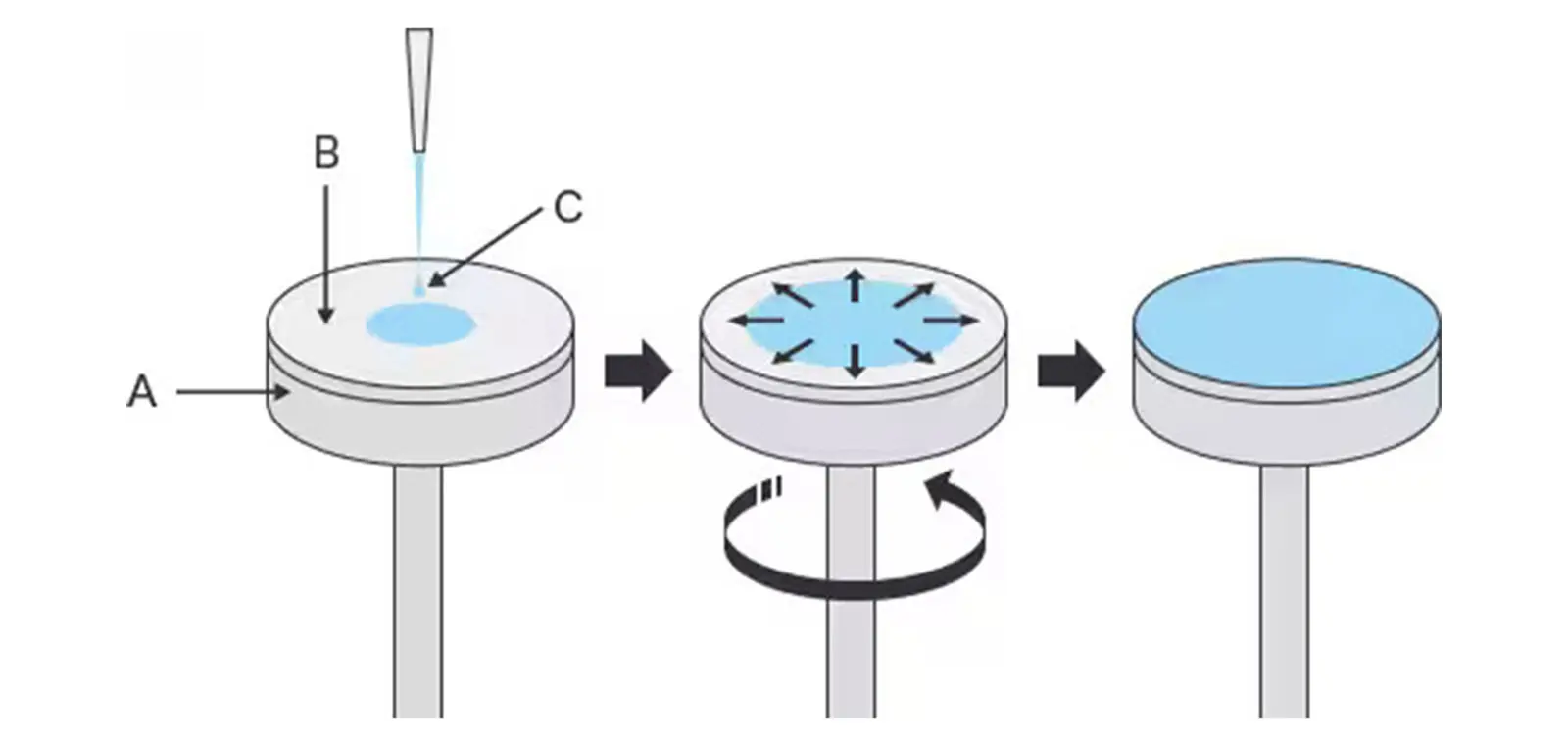

At present, most photoresist spraying methods use mechanical rotary spraying (gas/liquid two stream spraying), immersion coating, and other processes. Although the process is simple, there are also some shortcomings, such as uneven coating surface, stripe generation, poor viscosity, etc. These problems can lead to etching effects on the substrate in the future, affecting the quality of the final product.

The limitations of using spin coating technology for photoresist are as follows

● Uneven coating distribution: When coating deep wells or narrow channels, the spin coating process often leads to uneven coating distribution. During high-speed rotation of photoresist, due to the effect of surface tension, it is easy to form gaps in high aspect ratio structures or thin coatings on the sidewalls, resulting in unstable device performance.

● Edge glue bead problem: During the spin coating process, especially in the case of thick glue and square substrates, the edges of the photoresist will form glue beads, known as "edge glue". These edge adhesives can cause problems such as low pattern resolution, large size errors, or uneven sidewalls of the developed pattern during the exposure process.

● Difficulty in coating high aspect ratio structures: For structures with high aspect ratios, such as deep grooves and microstructures, the spin coating process is difficult to form a uniform coating in these areas, which can easily lead to gaps or uneven coating thickness.

The emergence of ultrasonic precision atomization spraying technology has brought a new turning point to the photoresist coating process. FUNSONIC ultrasonic spraying technology has shown significant advantages over traditional processes in photoresist coating, especially when dealing with complex structures. The characteristics are as follows:

● Uniform spraying: Ultrasonic atomization spraying technology converts liquid into extremely fine droplets through ultrasonic vibration, thereby achieving more precise and uniform spraying effects. Unlike spin coating, ultrasonic atomization does not cause uneven distribution of liquid in high aspect ratio structures due to surface tension.

● Adapt to substrates of any shape and texture: The droplet size generated by ultrasonic atomization is very uniform, which is particularly important when dealing with smaller feature sizes (less than 50 microns). This means that in deep grooves and microstructures, droplets can better fill subtle areas, avoiding problems such as gaps or uneven coating thickness.

● Controllability: Ultrasonic spraying technology can accurately control the dryness, humidity, and coating uniformity of the coating, ensuring that the thickness and density of each layer of coating remain consistent, which is particularly important for applications requiring photoresist preparation.

As a key material in semiconductor manufacturing, photoresist is irreplaceable in its importance. Ultrasonic atomization spraying technology can play a key role in the formation of surface coatings on photoresist. In the case of high aspect ratio feature structures on substrates such as electronic circuit boards, the deposition of coating layers is uniform and dense. Compared with traditional processes, the application of ultrasonic spraying technology has brought new solutions to the field of photoresist applications.