Optimization Of Ultrasonic Indium Coating Equipment For Target Coating Process

Ultrasonic indium coating machine is an advanced equipment that uses high-frequency vibration to achieve uniform coating of indium metal. Its core principle is to remove microbubbles and enhance material adhesion through ultrasonic energy. This process technology is widely used in electronic manufacturing, photovoltaics and other fields. The following is a detailed description of the working principle, application field, technical advantages and equipment type.

Working principle of ultrasonic indium coating machine

The ultrasonic generator converts the current into high-frequency electrical energy, and then converts it into mechanical vibration (20-30KHz) through the transducer. This vibration is transmitted to the welding area through the amplitude rod, and tens of thousands of high-frequency vibrations are generated on the indium coating tool head per second. Scraping and ironing enable the molten indium metal to completely penetrate and adhere to the surface of the substrate and penetrate into the microcavity; high-frequency vibration effectively precipitates microbubbles in the welding area; and achieves a firm combination of the indium coating layer and the substrate without flux.

Application fields of ultrasonic indium coating machine

Ultrasonic indium coating equipment is mainly used to uniformly penetrate indium metal into the surface of metal alloys, ITO ceramic glass, silicon dioxide and other substrates (target materials) to form a conductive induction film. It is widely used in the production and processing of semiconductor displays, touch screens, solar cells, recording media and other target parts.

Technical advantages of ultrasonic indium coating machine

1. Environmental protection

Use ultrasonic cavitation effect to directly remove the oxide layer on the metal surface, without chemical flux, avoiding toxic gases (such as fluoride) and wastewater discharge.

2. High efficiency and cost saving

High efficiency of indium coating: can be coated quickly, and the efficiency can be increased by more than 5 times compared with manual work.

Save materials: support aluminum wire to replace copper wire as solder, reduce material cost by 80%, and reduce the waste of precious metal indium (coating utilization rate reaches more than 95%); coating thickness can be controlled at 0.02-0.03mm.

3. Coating quality

The coating is uniform without blind spots, firmly bonded, and has no risk of cracks caused by microbubbles, which is suitable for high reliability scenarios.

4. Advanced technology

Supports I/O or 485 communication control, and can integrate automated operations; avoids the problems of uneven coating, easy to fall off, and difficult to control thickness caused by manual scraping.

Types of indium coating equipment

1. According to the processing method:

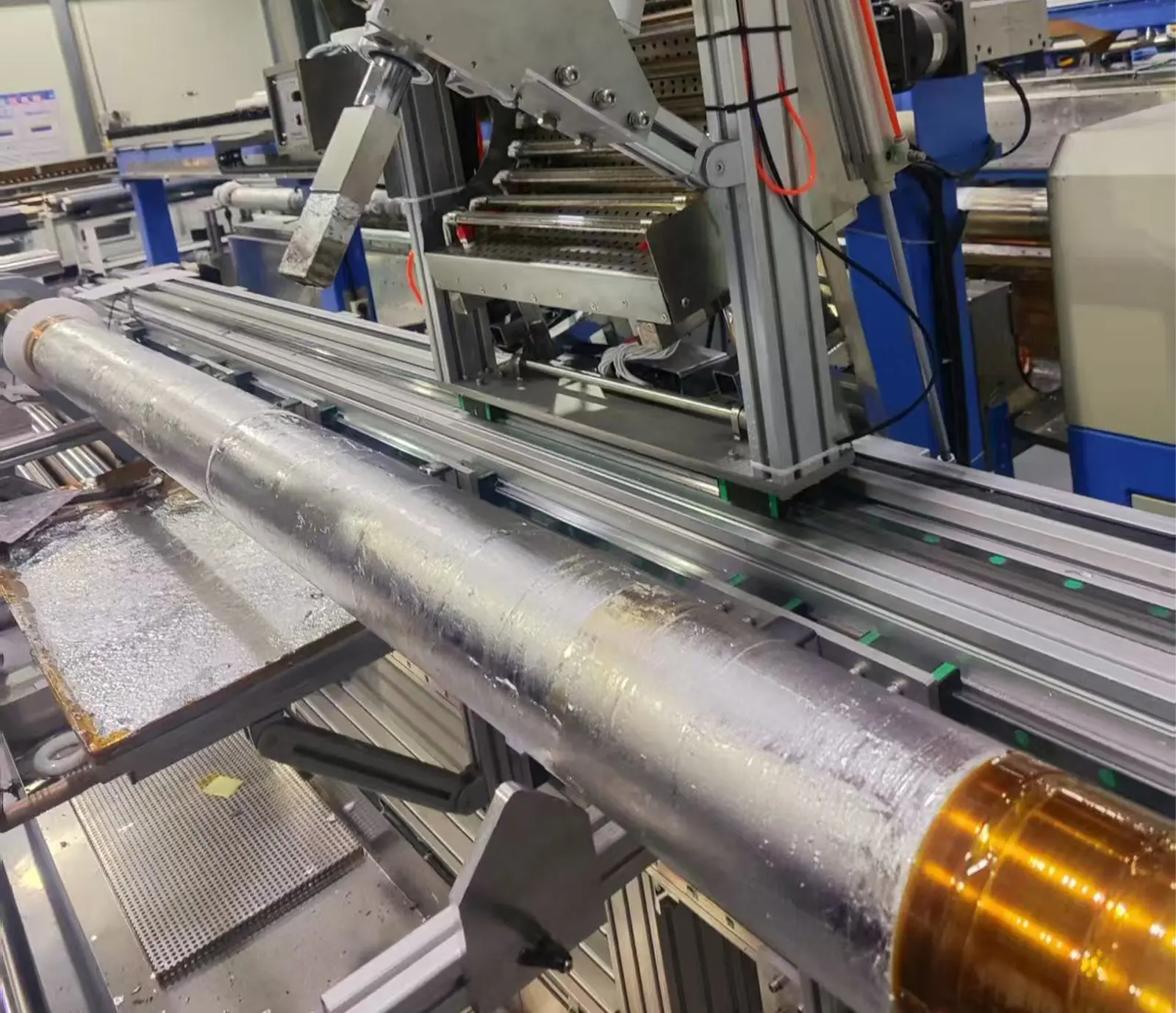

There are handheld ultrasonic indium coating machines and mechanical automated indium coating systems (equipment)

2. According to the shape of the product

The tool head of the ultrasonic indium coating machine has different models such as flat, inner circle, and outer circle according to the shape of the substrate. Different models of indium coating heads can also be customized according to customer needs, including extended arms to achieve the best overall coating effect.

Industry Development Trends

With the growing demand for automated and digital products, ultrasonic indium coating technology has gradually expanded to the manufacturing of key components for advanced control equipment. The advantages and characteristics of ultrasonic indium coating machines make them an important choice to replace traditional manual indium coating processes, especially in the semiconductor and new energy fields.

For more detailed parameters or customized solutions, please contact FUNSONIC for more information.