New Generation Perovskite Solar Cells, Ultrasonic Thin Film Preparation Process

Since the release of the "13th Five Year Plan for National Science and Technology Innovation" by the State Council in 2016, various departments have successively introduced policies related to the industrialization and development of perovskite solar cells, promoting the development of solar cells. In March 2023, the establishment of the Perovskite Photovoltaic Standard Special Group of the Standardization Technical Committee of the China Photovoltaic Industry Association began, further enhancing the process of sorting and improving the standard system for perovskite cells.

Among them, thin film preparation is an important part of the development of perovskite cells. Ultrasonic atomization spraying technology, as an advanced surface coating method, has shown significant advantages in the preparation of perovskite photovoltaic panels, promoting the application of perovskite materials in the field of new energy.

Advantages of ultrasonic spraying technology

● Uniform thin film distribution: Ultrasonic spraying technology converts perovskite materials into small particles through ultrasonic vibration and evenly sprays them on the substrate, reducing defects and unevenness and improving photoelectric conversion efficiency.

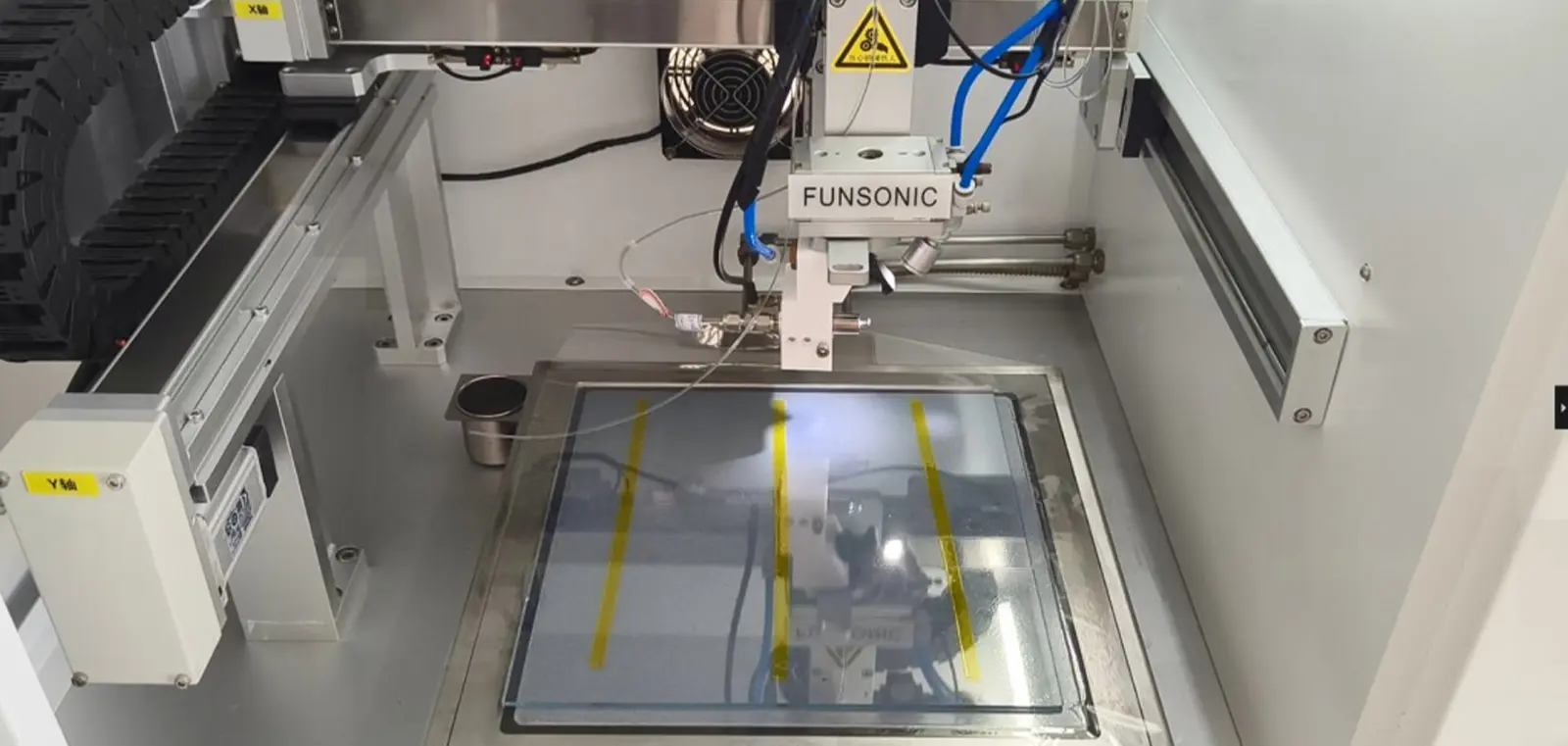

● Improving the quality of perovskite film: Ultrasonic spraying technology can control parameters such as spray angle, spray speed, and pressure to optimize the thickness, composition, and microstructure of the film, significantly improving the photoelectric conversion efficiency and stability of solar cells.

● Save raw materials: Traditional preparation methods may result in significant material waste, while ultrasonic spraying technology can accurately spray perovskite materials onto substrates, minimizing material usage, reducing costs, and contributing to environmental protection.

● Control flexibility: Ultrasonic spraying technology can flexibly adjust spraying parameters, such as spraying speed, spraying distance, and spraying time,

● Suitable for various substrates: Ultrasonic spraying technology is suitable for various substrates, including irregular substrates and flexible substrates, providing possibilities for applications in various fields such as wearable devices and building integrated photovoltaics (BIPV).

● Efficient preparation process: By precisely controlling the key parameters during the spraying process, a perovskite layer can be uniformly deposited on the surface of irregular CIGS bottom cells to prepare high-quality thin films, significantly improving the photoelectric conversion efficiency of solar cells.

Future prospects of perovskite solar cells

Through relevant tests, the perovskite solar cell using ultrasonic spraying technology achieved a conversion rate of 25.2% in the experiment, which is significantly better than traditional spraying cells. This not only improves the performance of perovskite solar energy, but also demonstrates the potential of ultrasonic waves in large-scale production.

Of course, as perovskite solar cells continue to improve, they will also face various challenges. On the one hand, with the continuous optimization and innovation of technology, it is necessary to improve the comprehensive performance of batteries; On the other hand, as a manufacturer of FUNSONIC ultrasonic atomization spraying equipment, we also need to continuously strive with the large-scale production of the photovoltaic industry, leverage the advantages of ultrasonic application, provide users with more efficient and suitable spraying processes and products, and contribute to the rise of green energy.