New Breakthrough In Fuel Cell Coating: The Accuracy And Economic Advantages Of Ultrasonic Atomization Spraying

The application advantages of ultrasonic atomization spraying technology in fuel cells are remarkable, especially in improving catalyst utilization efficiency, optimizing coating uniformity, and reducing production costs. The following combines technical principles with industry practices to elaborate on its core advantages:

1. High material utilization and cost control

a. Reduce waste of precious metal catalysts

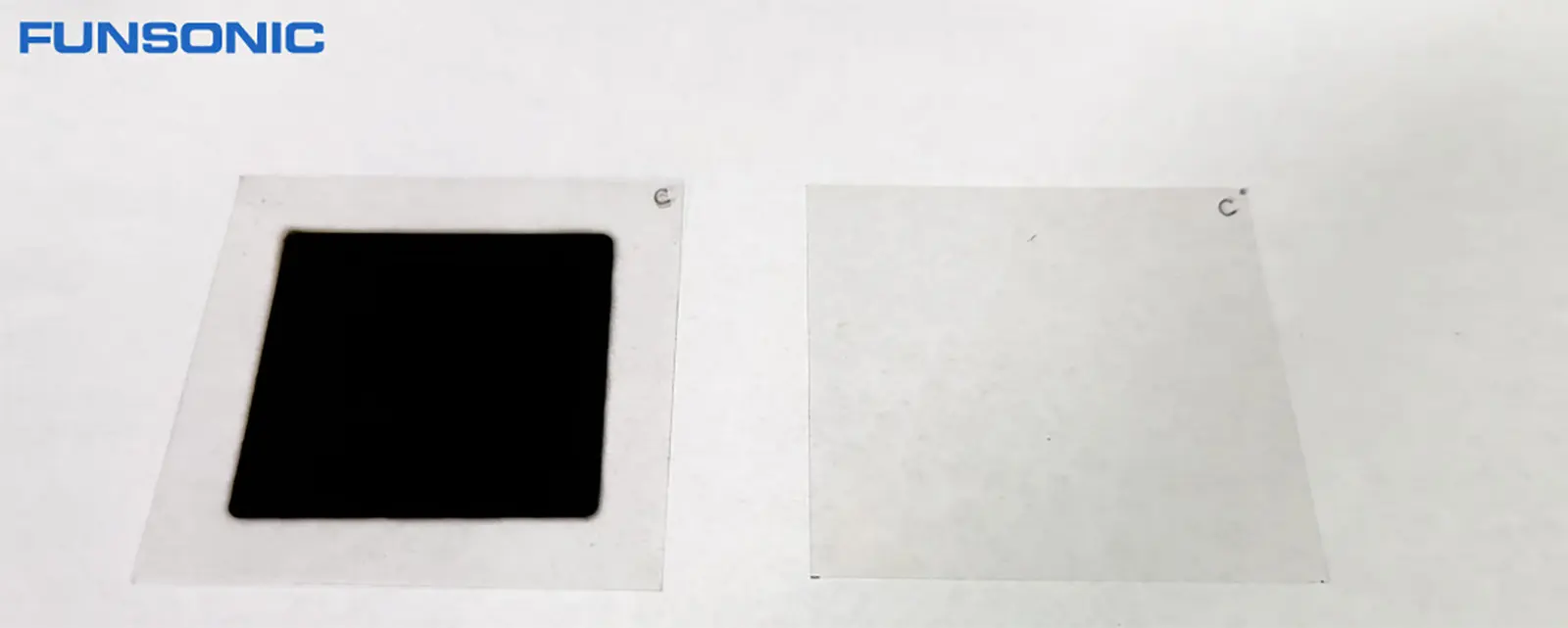

Traditional spraying techniques (such as air spraying) reason paint to rebound and splash due to high-pressure gas, and the fabric utilization fee is solely 20%-30%. Ultrasonic spraying makes use of high-frequency vibration to atomize liquid, barring high-pressure gas, and the fabric utilization charge can attain greater than 90%, notably decreasing the consumption of valuable metals such as platinum and iridium. For example, in proton alternate membrane gas cells (PEMFCs), the utilization charge of platinum catalysts has multiplied from 50% in normal strategies to 90%, and the cloth value has been decreased by means of 50%.b. Nano-level precision control

By adjusting the ultrasonic frequency, the particle size of the atomized droplets can be controlled at 10μm-50μm, or even reach nano-level precision (such as tens of nanometers), achieving uniform deposition of ultra-thin coatings (5-15 microns) and reducing material redundancy.

2. Coating uniformity and electrode performance improvement

a. Avoid catalyst agglomeration

Ultrasonic vibration disperses the particles in the catalyst suspension synchronously during the atomization process, breaks the agglomeration phenomenon, forms a porous and dense catalyst layer structure, increases the specific surface area, and improves the electrochemical reaction activity. For example, after the dispersion uniformity of carbon black and platinum-based catalysts is improved, the current density and durability of the electrode are significantly enhanced.

b. Complex surface adaptability

Ultrasonic spraying is appropriate for microscopic hard surfaces such as carbon paper and proton trade membranes of gasoline diffusion layers. The membrane cloth is stored flat thru vacuum adsorption and heating platform to keep away from swelling or deformation throughout the spraying process, making sure sturdy bonding between the coating and the substrate.

3. Process Automation and Large-Scale Production

a. Efficient Mass Production Capability

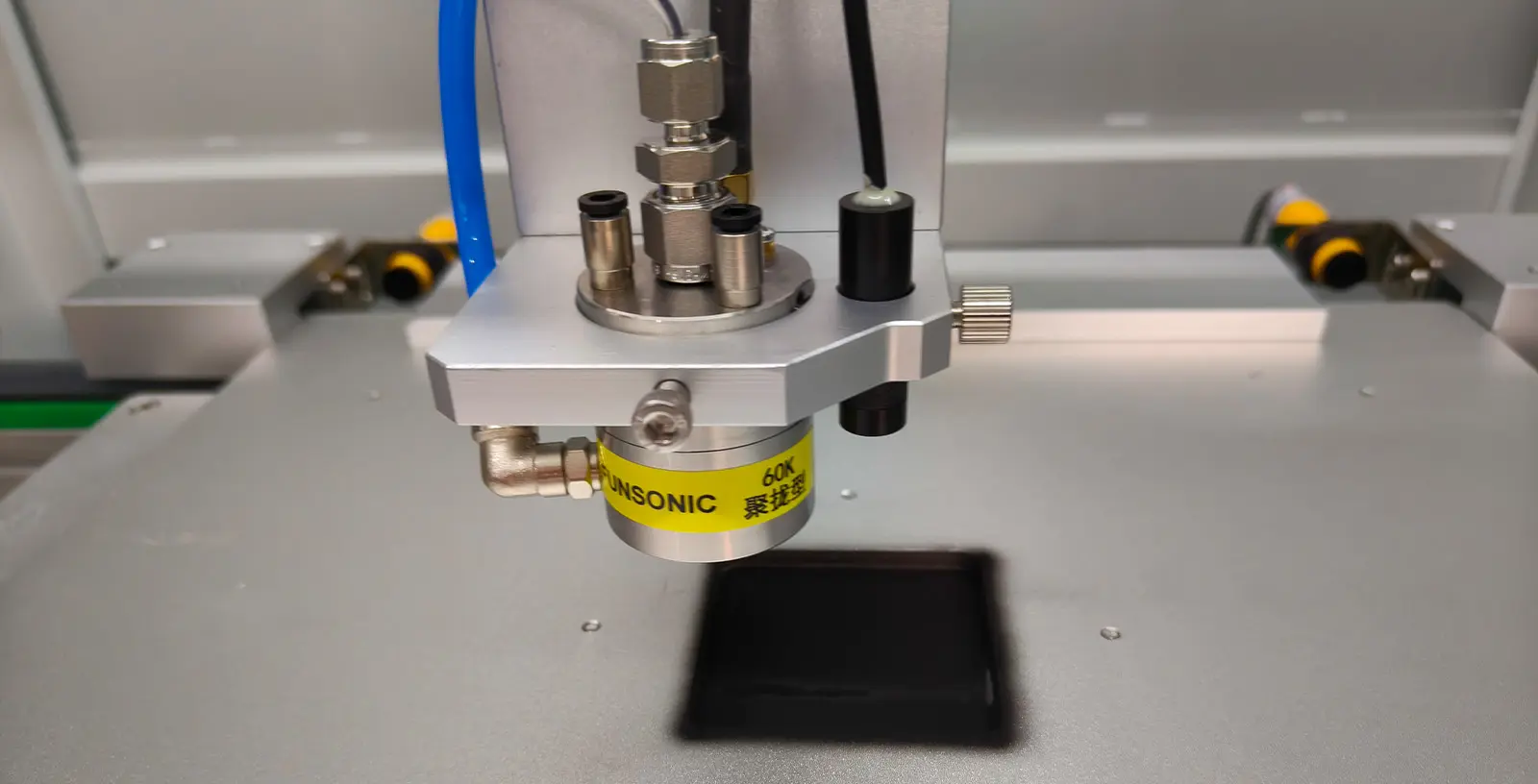

Multi-nozzle array design supports wide-width spraying, such as the FUNSONIC perovskite-specific ultrasonic spraying equipment. The entire equipment uses 15 nozzles integrated to achieve 24-hour uninterrupted spraying production, automated three-axis motion system, improve production efficiency and reduce manual intervention.

b. Precise and controllable parameters

Parameters such as spraying rate, substrate temperature, moving path, spraying size, etc. are all precisely controlled through the computer PLC system settings; ensuring that the coating thickness error is less than 5% and the load consistency is high.

4. Environmental protection and sustainability

a. Low pollution, low loss

Ultrasonic spraying only uses a small amount of organic solvents (diluents) to assist, and the process can greatly reduce volatile organic compound (VOC) emissions. The spraying method adopts non-contact spraying technology, which effectively avoids physical damage to the surface of the base film material by the external carrier, and also extends the service life of the nozzle assembly.

b. Energy-saving characteristics

Compared with regular high-temperature sputtering or chemical vapor deposition (CVD), ultrasonic spraying can be accomplished at room temperature or low temperature, decreasing electricity consumption by using 30%-50%.

5. Summary

Ultrasonic atomization spraying technological know-how has end up the core science for decreasing prices and growing effectivity in the gasoline mobilephone enterprise thru its blessings such as high-precision atomization, environment friendly cloth utilization, and procedure automation. Its application in key components such as membrane electrode assemblies (MEAs) not only improves battery performance, but also provides technical support for the scale and sustainable development of the hydrogen energy industry.

FUNSONI now provides free coating proofing services to customers and friends, and welcomes friends from all walks of life to contact us for proofing.