How Ultrasonic Empowers Extraction Technology

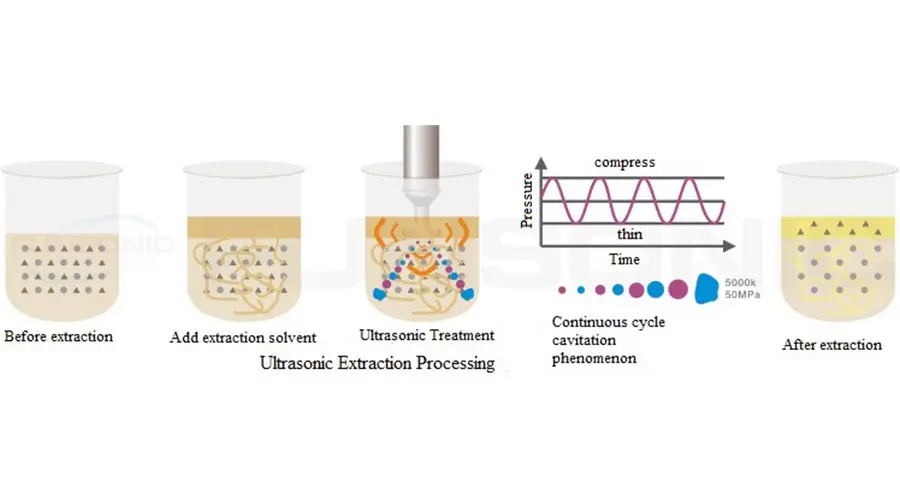

Ultrasonic extraction technology is an advanced technology that uses the comprehensive effects of cavitation, vibration, crushing, stirring, etc. generated by ultrasound to extract natural product ingredients. It increases the penetration of solvents and the precipitation of material components by destroying cell tissues, thereby improving the extraction rate and shortening the extraction time, achieving efficient and rapid extraction of cell contents. Different parameters are required for different plant ingredients according to the frequency, intensity and time of ultrasound.

1. Introduction to ultrasonic equipment

FUNSONIC ultrasonic sonochemical treatment system: It consists of two parts: ultrasonic vibration components (host) and ultrasonic generator (also known as processor, unit, assembly).

The ultrasonic vibration part consists of ultrasonic transducer, amplitude transformer, tool head (transmitter head), etc.

The transducer converts the high-frequency electrical energy provided by the ultrasonic generator into 20KHz~40KHz mechanical energy, that is, ultrasonic waves.

The ultrasonic generator is connected to 220V50HZ civil electricity, and after it is turned on, it drives the vibration component to work, and the tool head emits ultrasonic energy into the liquid material to be treated.

2. Working principle and application fields:

When the tool head of the ultrasonic sonochemical treatment equipment is immersed in the liquid and the equipment is turned on, special chemical and physical reactions will occur in the liquid medium, namely ultrasonic cavitation. Acoustic cavitation forms a jet of tiny bubbles. The cavitation bubbles are compressed and expanded to increase the temperature of the liquid around the cavity and produce local hot spots; very high pressure and acceleration are generated at the moment of bubble rupture, thereby producing extreme physical and chemical conditions in the liquid. This makes ultrasonic sonochemical equipment more and more widely used in various chemical fields and biological industries, such as extraction, crushing and mixing, emulsification, dispersion and stirring, defoaming and degassing to accelerate reactions.

3. Selection of ultrasonic sonochemical treatment system

There are three types of ultrasonic processors for liquid treatment: 500-1000W (experimental scale), 1500W (pilot scale) and 1500-3000W (industrial scale). The system works in flow mode (pipeline circulation) or in quantitative mode (inserted into the reactor), and there is no limit on the total amount of liquid treated. Users can use small-scale (experimental) equipment to perform ultrasonic processing, analyze parameter effects, and then decide on the appropriate ultrasonic system and configuration.

4. Ultrasonic extraction technology is widely used in many fields, including:

Pharmaceuticals: Ultrasonic extraction technology performs well in the extraction of Chinese herbal medicines, and can replace traditional shearing methods to achieve efficient, energy-saving and environmentally friendly extraction. Through the cavitation effect of ultrasound, the effective ingredients in Chinese herbal medicines can be extracted quickly and efficiently.

Food: Used for the extraction of food ingredients, such as spices, pigments, etc. High value-added ingredients can also be extracted from rice bran, wheat bran, soybeans, corn germs, etc.

Agriculture: Used for the extraction of plant active ingredients. Ultrasonic circulation extraction technology has the characteristics of short time and simple operation in pollen cell wall breaking technology. The wall breaking rate meets the production process requirements and greatly reduces production costs.

Environmental science: Used for issue evaluation of environmental samples. By mixing water samples with appropriate solvents and making use of ultrasonic energy, natural pollution can be efficaciously released, which helps subsequent evaluation and detection.

Industrial raw materials: Used for component extraction and analysis of industrial raw materials. Ultrasonic extraction technology can be used to accelerate chemical reactions and separate products. For example, ultrasonic extraction technology can be used to accelerate chemical reactions and increase the yield of products. At the same time, ultrasound can also be used to separate and purify chemical products to improve the quality and purity of products.