From droplets to thin films: process optimization in ultrasonic spraying

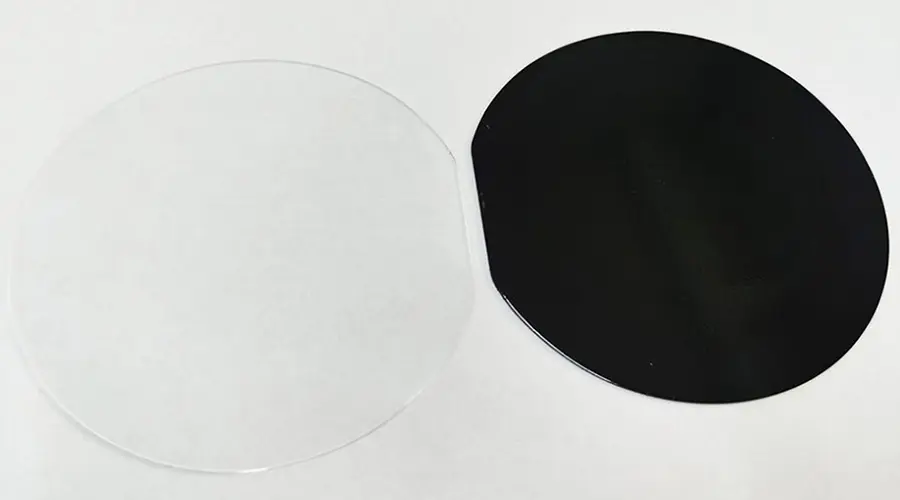

In the ultrasonic atomization spraying process, coating thickness and uniformity are the core indicators that determine product performance (such as optical properties, corrosion resistance, and conductivity). The amplitude and frequency of the ultrasonic wave, the properties of the liquid, and the amount of liquid supplied per unit time are key parameters for spraying process control, which directly affect the dynamic behavior of the droplets and work together in the process of liquid atomization → coating film formation.

1. The regulating effect of amplitude

a. The influence of amplitude on coating thickness

The amplitude represents the energy output intensity of the vibration system (nozzle end), that is, the amplitude of vibration, which directly affects the atomization size and deposition rate of droplets:

High amplitude: High energy output breaks the liquid into micron-sized droplets, reducing the deposition amount per unit area, and forming an ultra-thin coating (such as nano-level functional coating). However, when the amplitude is too high, droplet splashing may additionally motive neighborhood accumulation of the coating and uneven thickness.

Low amplitude: The droplet dimension is large, gravity dominates the deposition process, and it is effortless to shape a thick film. However, under low amplitude, the droplet is prone to spreading-contracting oscillation after hitting the substrate, resulting in edge thickening (coffee ring effect).

b. Effect of amplitude on uniformity

Optimization range: Experiments exhibit that when the amplitude is 10~30μm, the droplet diameter distribution is the narrowest (D15≈45μm) and the deposition uniformity is the best.

Extreme risk: When the amplitude exceeds the necessary value, the droplet kinetic electricity is too high, and the chance of rebounding after hitting the substrate increases, forming micropore defects.

2. Frequency: The key variable of droplet size and distribution

a. Mechanism of action

Frequency determines the period of ultrasonic vibration and affects the stability of droplet formation. High frequency (>100kHz) produces smaller droplets, but has high requirements for liquid materials (such as uniformity, viscosity, and solid content), otherwise it may cause atomization instability; low frequency (<50kHz) has larger droplets and more uniform atomization, but the amount of deposition on the substrate surface per unit time becomes larger.

b. Impact on uniformity

High frequency: The droplet size is small and easily disturbed by the external carrier airflow, resulting in thinning of the edge coating.

Low frequency: The droplet size is large and needs to be combined with high amplitude to avoid agglomeration, which is suitable for high viscosity liquids.

3. Liquid properties: Intrinsic constraints of material properties

a. Viscosity

High viscosity: high amplitude + low frequency is required to overcome cohesion, otherwise it is easy to clog the nozzle or form a thick film.

Low viscosity: prone to over-atomization, the amplitude needs to be reduced to prevent excessive droplet refinement and cause porous coating.

b. Surface tension

Low surface tension: droplets are easy to spread and improve uniformity, but the atomization pressure needs to be controlled to avoid splashing.

High surface tension: high-frequency vibration is required to assist in breaking, otherwise the droplet size is too large.

c.Density and volatility

High-density liquid: greater amplitude is required to make sure that the droplets penetrate the airflow to attain the substrate.

Volatile liquid: atomization energy needs to be controlled to avoid premature evaporation of the solvent and cause coating defects.

4. Conclusion

Amplitude, frequency and liquid properties constitute the "golden triangle" of coating process.

Amplitude determines the kinetic energy of droplets, affecting deposition efficiency and defect control.

Frequency regulates the atomization scale, balancing thickness accuracy and production efficiency.

Once the liquid properties used by the user and the substrate and coating requirements to be sprayed are determined, the process boundaries need to be set during the experiment. By selecting ultrasonic spray systems of different specifications and models, the corresponding parameters, including flow rate, are repeatedly adjusted to achieve the best operating effect and coating requirements, and finally the appropriate ultrasonic spray equipment model is determined.