Application Scenarios and Advantages of Ultrasonic Dispersion and Emulsification

1. Application Principle

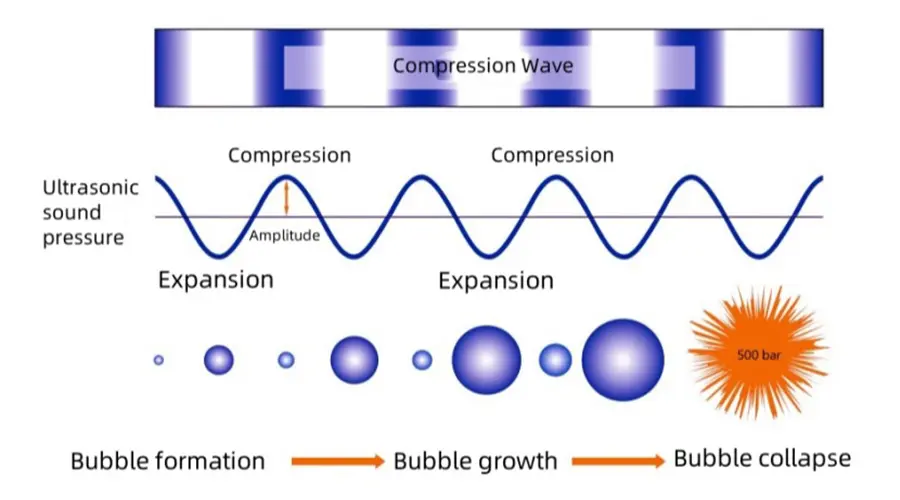

Ultrasonic dispersion emulsification technology is based on the cavitation effect of ultrasound in liquid. When ultrasound propagates in liquid, the high-frequency vibration of 20KHz~40KHz reasons a drastic alternate in the nearby stress of the liquid, producing a giant range of tiny bubbles. These bubbles grow, enlarge and fall down right way below the motion of ultrasound, releasing instant excessive temperature (about 5000 K) and excessive stress (about a thousand atm), accompanied through sturdy microjets. This technique can correctly damage up and separate particle agglomerates, or promote two immiscible drinks (such as oil and water) to structure a uniform and secure emulsion.

2. Application scenarios

a. Food industry

Used in the preparation of emulsified drinks, sauces, margarine, etc., including aging treatment in wine brewing; improve the delicate taste and product stability, and extend the shelf life.

b. Cosmetics production

Uniformly disperse energetic components (such as vitamins, plant extracts), decorate the absorbability and efficacy of emulsions and essences.

c. Medical field

Prepare nanoemulsions to enhance drug solubility and bioavailability, or for dispersion cure of vaccine adjuvants.

In typical Chinese medication preparations, thru ultrasonic extraction, the extraction charge of alkaloids, saponins, and flavonoids in medicinal substances is substantially improved with the aid of extra than 50% in contrast with typical processes;

d. Preparation of nanomaterials

Break the agglomeration of nanoparticles, achieve uniform dispersion of substances in the base liquid, and optimize conductivity, catalysis and different properties.

e. Chemical and coatings

Mix high-viscosity resins, paints, or put together oil-water secure emulsions to enhance product uniformity and storage stability.

f. Biotechnology

Break cell walls/membranes to extract intracellular elements (such as DNA, protein), which are used in vaccine improvement and biopharmaceuticals.

g. Environmental protection

Emulsify oily wastewater into micron-sized particles for subsequent separation or degradation treatment. Such as the extraction of biodiesel.

h. New energy industry

Disperse lithium battery electrode slurry (such as wonderful electrode material) to enhance battery energy density and cycle life. Extraction of polycrystalline silicon and monocrystalline silicon materials, education of graphene slurry.

i. Daily chemical substances and pharmaceuticals

Achieve secure mixing of immiscible drinks (such as quintessential oils and water-based solutions), changing usual chemical emulsification processes.

3. Technical advantages

a. High effectivity and excessive uniformity

Cavitation effect: 20-40 kHz ultrasound produces micron-level bubble collapse, and immediately excessive strain (1000 atm) strongly breaks up agglomerated particles.

Narrow particle dimension distribution: By adjusting energy and time, the particle measurement can be precisely managed (such as nanoemulsion D50≤200 nm), which is higher than mechanical stirring or high-pressure homogenization.

b. Low temperature treatment and ingredient protection Non-thermal process: The treatment temperature is decrease than 50°C to keep away from inactivation of heat-sensitive components (enzymes, probiotics, vitamins). Green process: Reduce the quantity of emulsifier brought to meet the strict protection necessities of the meals and pharmaceutical industries.

c. Precise controllability

Flexible parameter adjustment: frequency, amplitude, and processing time can be programmably managed to adapt to unique structures (viscosity 1-10,000 cP).

Continuous production: built-in with the pipeline device to realise automatic meeting line operations in the dairy, cosmetics and different industries.

d. Versatility

Emulsification and demulsification twin mode: low frequency (20 kHz) is used for emulsification and dispersion, and excessive frequency (above a hundred kHz) can demulsify and deal with oily wastewater.

Wide compatibility: helps multiphase blended structures such as liquid-liquid, solid-liquid, and gas-liquid.

e. Environmental safety and economy

Low power consumption: 30%-50% electricity saving in contrast to high-pressure homogenizers (only five hundred W is required for a processing potential of 1 L/min).

Low upkeep cost: no mechanical put on parts, and the ultrasonic probe lifestyles is >5000 hours.

f. Scalability

Full-scale coverage: from laboratory stage (milliliter level) to industrial stage (ton-level reactor, pipeline non-stop processing), technique parameters can be seamlessly scaled up..

4. Equipment selection

FUNSONIC liquid handling equipment supports customized solutions. Hangzhou FUNSONIC is equipped with sonochemical small and pilot test equipment, which can provide customers with free proofing activities. According to the materials and requirements you provide and the results obtained through ultrasonic treatment, we can formulate appropriate product solutions. Customers and friends are welcome to come for consultation and material testing

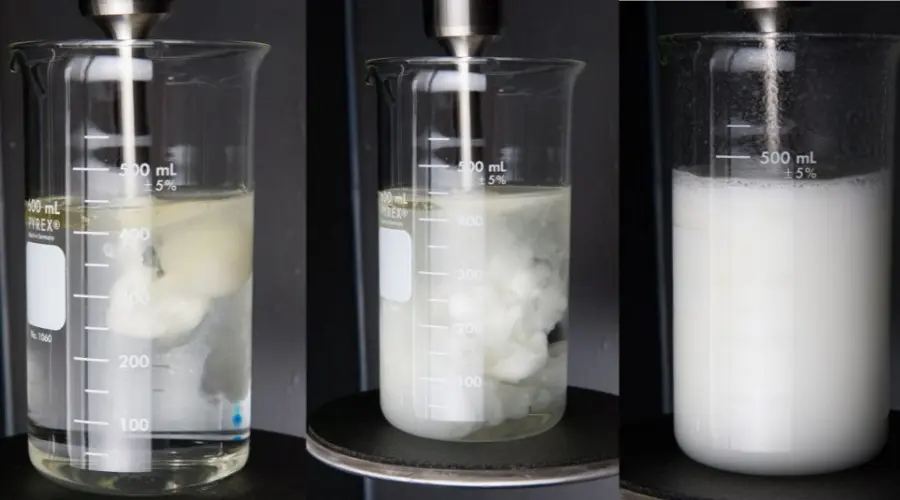

5. Introduction to ultrasonic sonochemical treatment system

It consists of two parts: ultrasonic generator and ultrasonic vibration component. The ultrasonic generator (also known as driving power supply), including rectification circuit, oscillation circuit, amplification circuit, feedback circuit, tracking circuit, etc., is used to generate high-frequency and high-power current to drive the ultrasonic vibration component to work. The ultrasonic vibration component mainly includes high-power ultrasonic transducer, amplitude transformer, transmitter head (also known as tool head, made of stainless steel or titanium alloy), which is used to generate ultrasonic vibration; the transmitter head is immersed in the liquid to transfer the vibration energy to the liquid.

6. Summary

Ultrasonic dispersion emulsification technology has shown significant advantages in many fields such as food, medicine, and new energy due to its high efficiency, precision, and environmental protection. Its physical action mechanism avoids the dependence on chemical additives, and at the same time provides reliable technical support for industrial continuous production and product performance optimization.