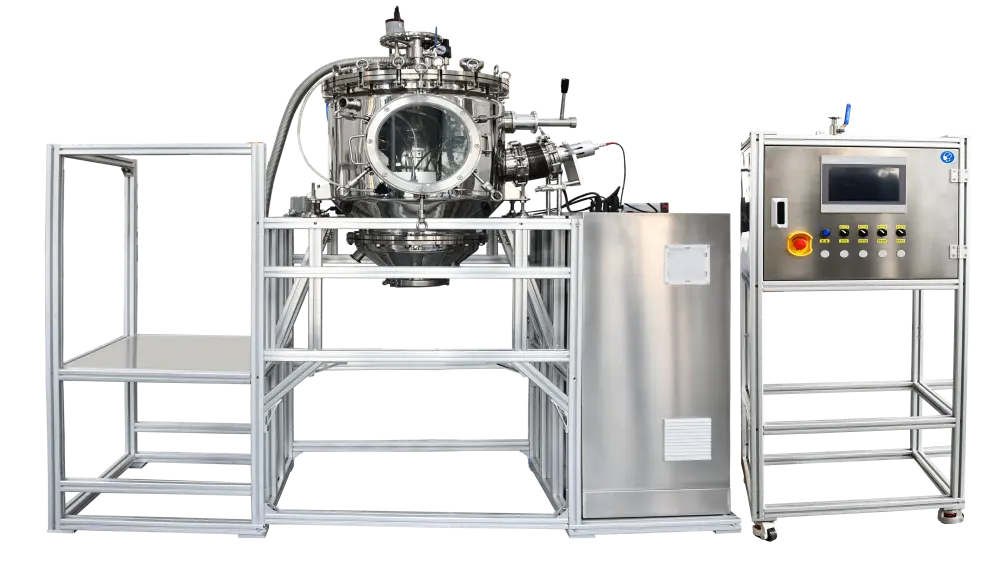

Application of Ultrasonic Metal Powder Equipment in Preparing Solder Powder and Indium Powder

Ultrasonic metal powder making technology has significant advantages in the preparation of solder powder and indium powder, especially in particle size control, sphericity and low oxygen content. The following are its main applications and technical features:

1. Application of solder powder

Electronic welding materials:

Electronic welding materials: Solder powder (such as tin-based alloy) organized by means of ultrasonic atomization has excessive sphericity, slim particle measurement distribution and low oxygen content, which is appropriate for the manufacturing of high-precision solder paste and is extensively used in SMT (surface mount technology) and microelectronic packaging.

3D printing and additive manufacturing:

Solder powder can be used for 3D printing of digital components, such as bendy circuits and micro-welding structures. Its uniform particle measurement helps to enhance printing accuracy and conductivity.

Powder metallurgy:

Electronic welding materials: Solder powder (such as tin-based alloy) organized by means of ultrasonic atomization has excessive sphericity, slim particle measurement distribution and low oxygen content, which is appropriate for the manufacturing of high-precision soldeSolder powder can be used to manufacture high-density, low-porosity metal composites, fabulous for digital connectors and precision mechanical parts.

2. 2.Application of indium powder

Semiconductor and photovoltaic industry:

Indium powder is the key uncooked cloth for making ready ITO (indium tin oxide) targets, which is used to manufacture obvious conductive videos and is extensively used in liquid crystal shows (LCDs), photo voltaic cells and contact screens.

Low-temperature solder:

Indium and its alloys (such as indium-tin) have extraordinarily low melting factors and are appropriate for low-temperature welding, such as the packaging of optoelectronic units and precision sensors.

Nuclear enterprise and aerospace:

High-purity indium powder can be used for sealing substances in nuclear reactors and thermal interface substances in spacecraft.

3.Technical advantages

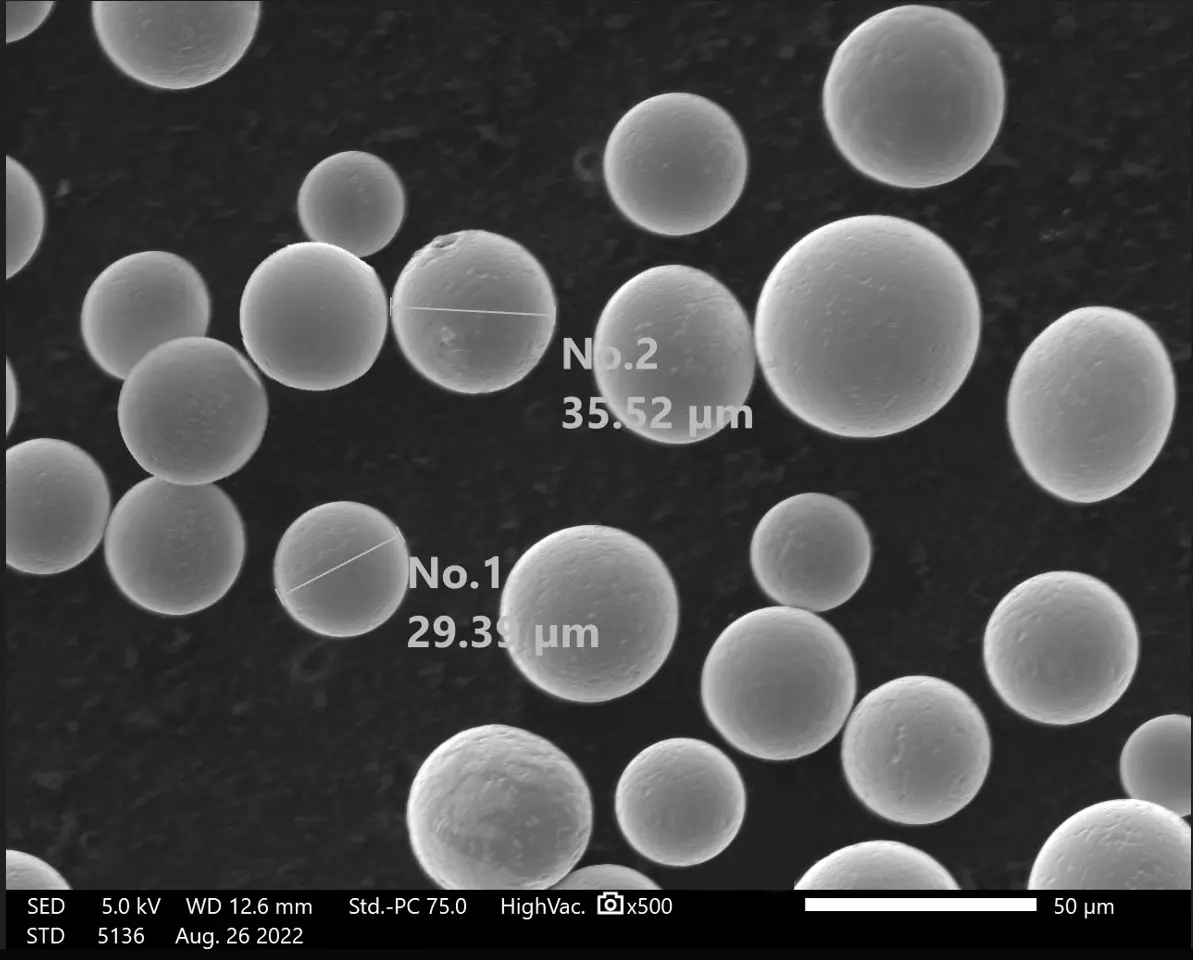

High sphericity and uniform particle size:

The powder organized by using ultrasonic atomization has excessive sphericity and properly fluidity, which is appropriate for high-precision coating and printing.

Low oxygen content:

Compared with standard atomization techniques (such as fuel atomization), ultrasonic atomization can notably limit the oxygen content material of powder and enhance welding reliability and conductivity.

Environmental safety and power saving:

Ultrasonic atomization gear has a easy shape and low power consumption, which is appropriate for small-batch high-value-added production.

4.Future development trends

Atomization of high melting point metals:

By improving the atomizer head material (such as titanium alloy + ceramic coating) and cooling technology, it may be expanded to the atomization of higher melting point metals in the future.

Intelligent control:

Combined with AI algorithms to optimize atomization parameters (such as frequency, amplitude), further improve the uniformity and production efficiency of powders.