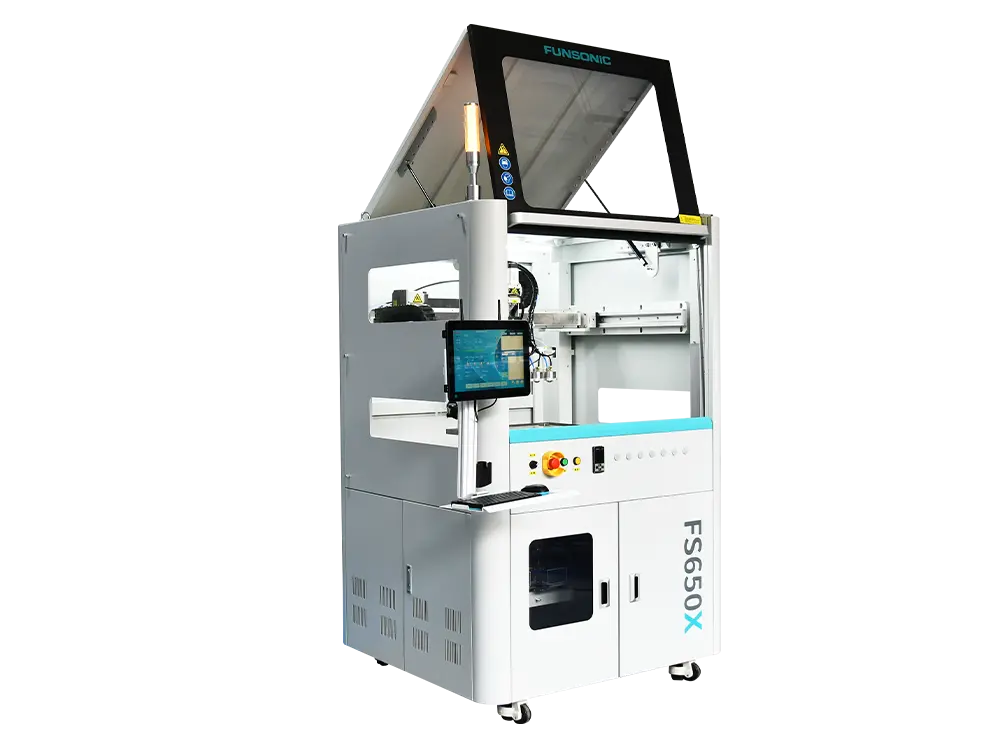

Floor Standing Ultrasonic Multi-nozzles Coating System FS650X-5

Advantage

Product Configuration

-

Conventional Arrangement

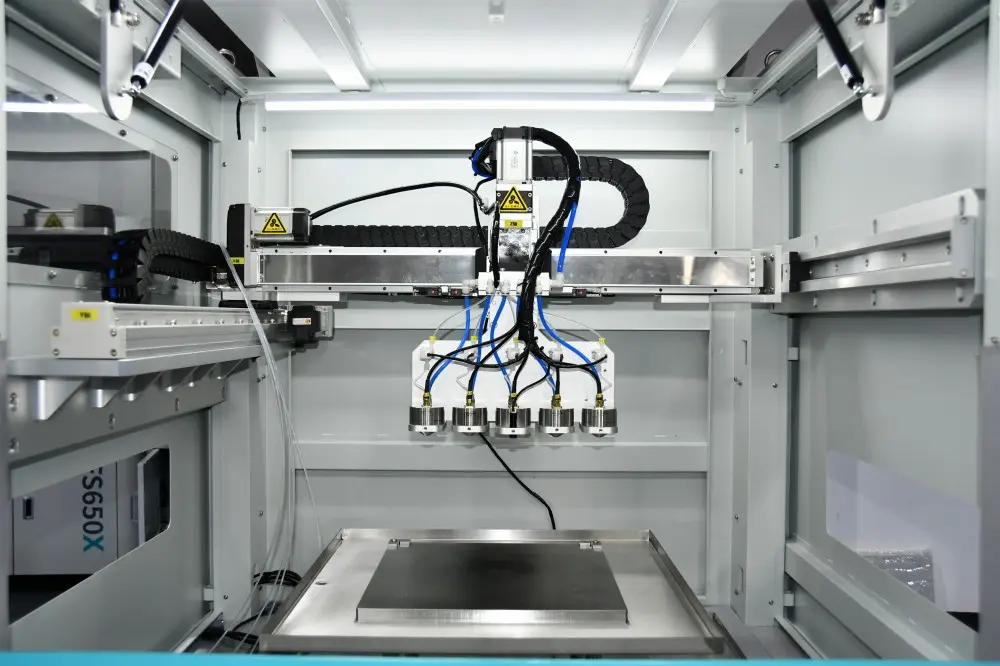

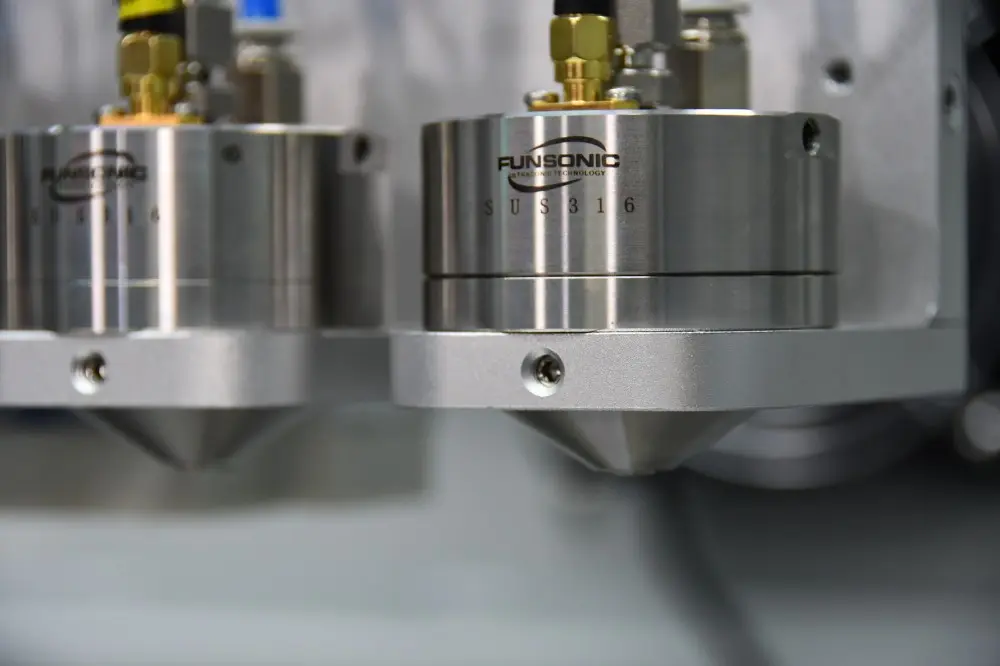

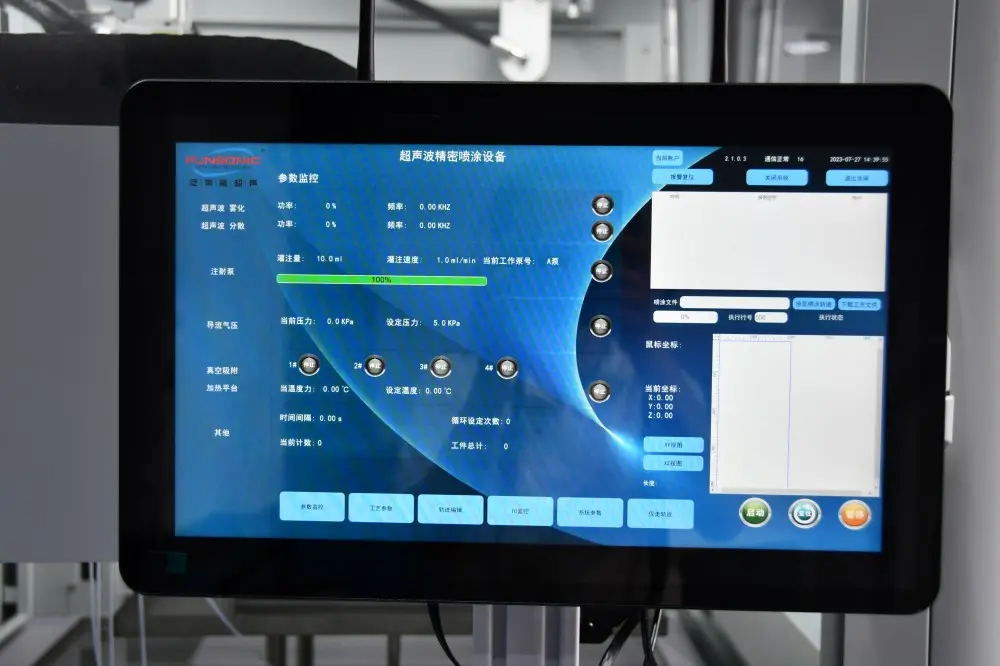

1. Ultrasonic nozzle: optional 20-200Khz multiple nozzle systems

2. Ultrasonic power supply: fully CNC precision power supply, fully intelligent frequency following, frequency tracking, stable performance

3. Liquid supply equipment: precision injection pump+biological grade sampler, liquid supply accuracy of 0.1 μ L/min

4. Sports system: XYZ three-axis imported servo motor+fully enclosed precision screw module

5. Operating System: Based on the Windows system, FUNSONIC independently developed a spraying control system, PLC control, and full-color touch screen

-

Optional Configuration

1. Ultrasonic dispersion liquid supply system: It can continuously disperse and stir nanoparticles during the spraying process, effectively reducing the precipitation phenomenon of the spraying liquid and greatly improving the uniformity of the film layer

2. Heating and drying platform: using aviation aluminum porous platform or precision microporous ceramic platform, precise temperature control of 200 ℃ (higher heating temperature can be customized)

3. Vacuum adsorption platform: equipped with multiple vacuum generators, can be controlled by zones, and accurately adsorbs film substrates without deformation.

4. Nozzle alignment device: using laser alignment to quickly align the material spraying position.

We can also customize other configurations according to your needs.

Product Application

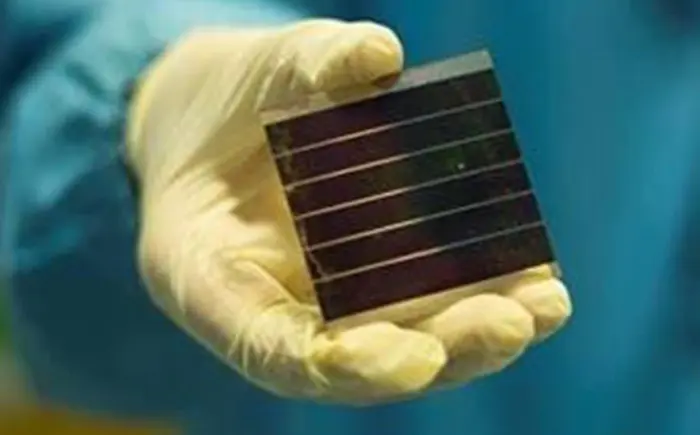

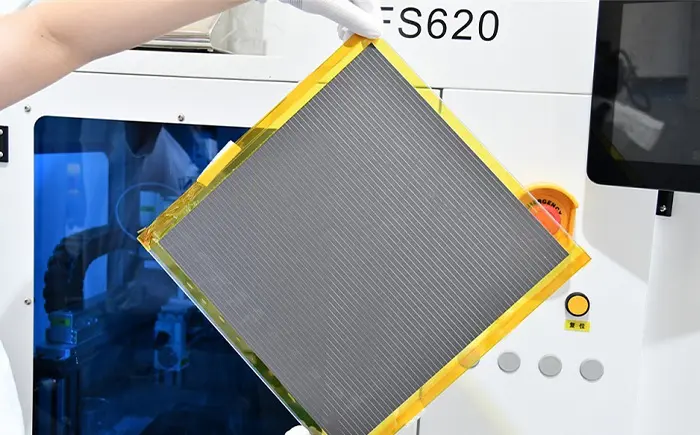

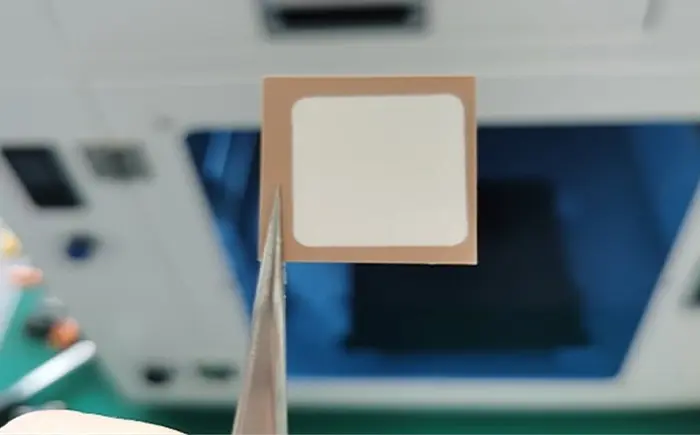

2. Manufacturing of photovoltaic cells: Spraying photosensitive materials and anti reflective coatings.

3. Coating for medical devices: Coating biocompatible coatings on implants and medical devices.

4. Automotive industry: Protective coating for coating interior parts or fine components.

5. Optical coating: Apply anti reflective or scratch resistant coatings on lenses and optical components.

6. Furniture industry: Spray protective coating on the surface of delicate furniture.

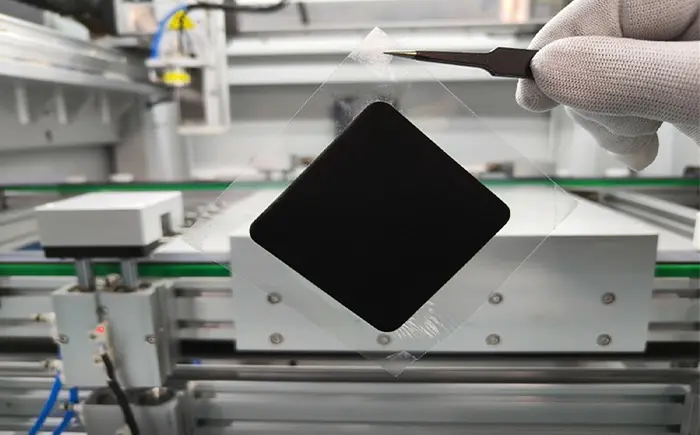

7. Thin film solar cells: Spraying conductive and photosensitive films.