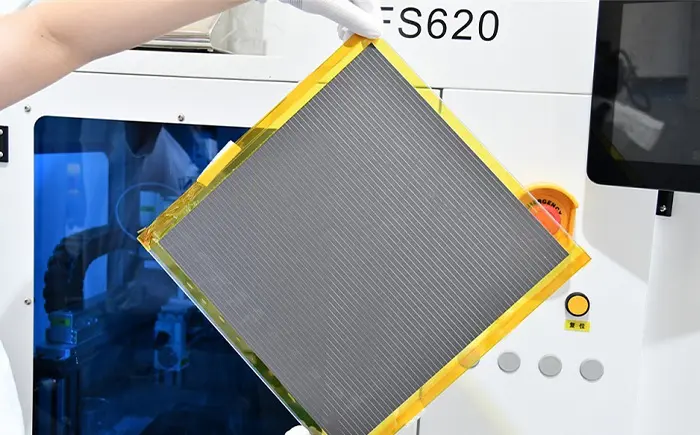

Floor Standing Ultrasonic Conveyor Coating System FS650X

Advantage

Product Configuration

-

Conventional Arrangement

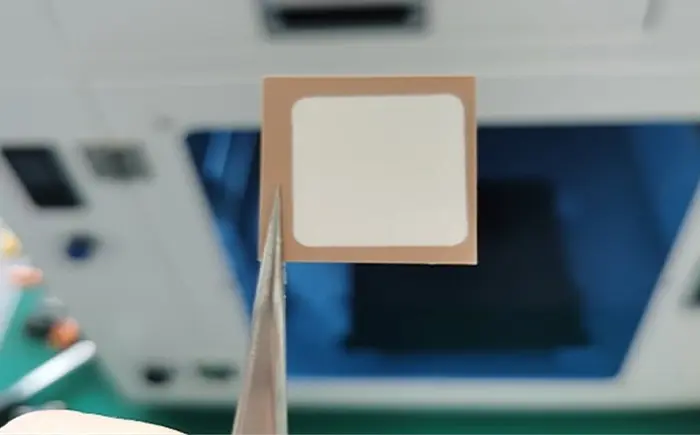

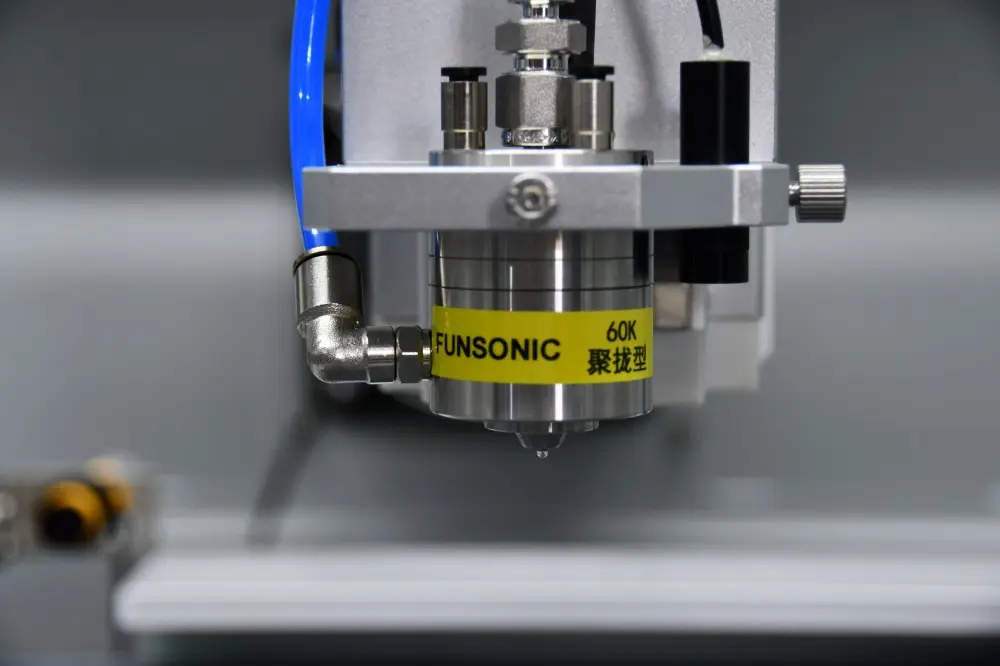

1. Ultrasonic nozzle: high-frequency low-power atomizing head

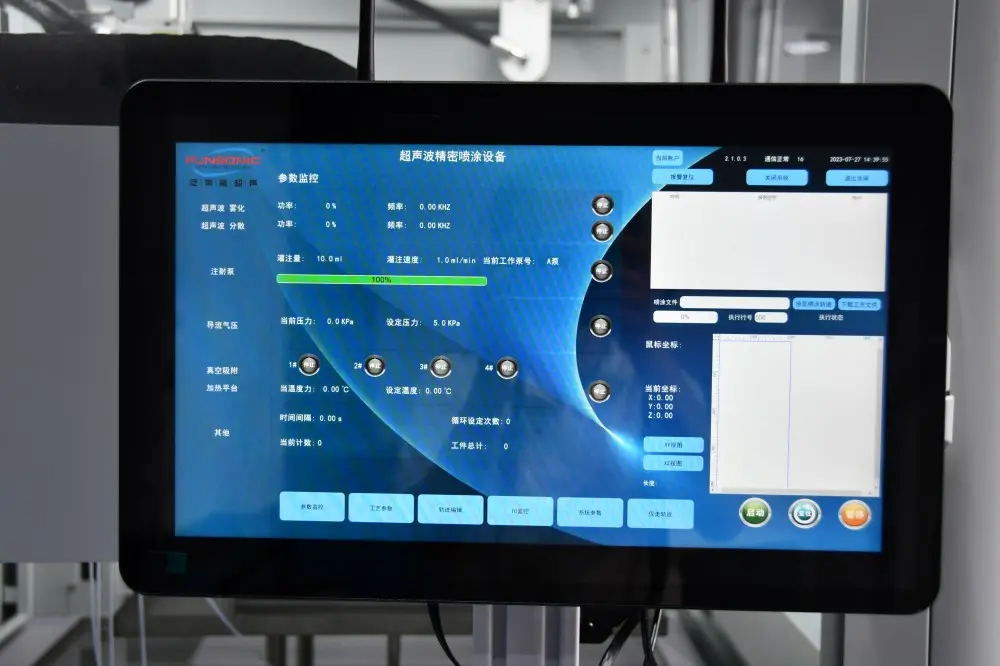

2. Ultrasonic electric box: specially designed to match ultrasonic atomization nozzles, FUNSONCI independently develops high-frequency precision electric boxes, LCD control panels, and can switch between Chinese and English freely

3. Liquid supply system: Precision injection pump (manual, self pumping, constant flow options available)

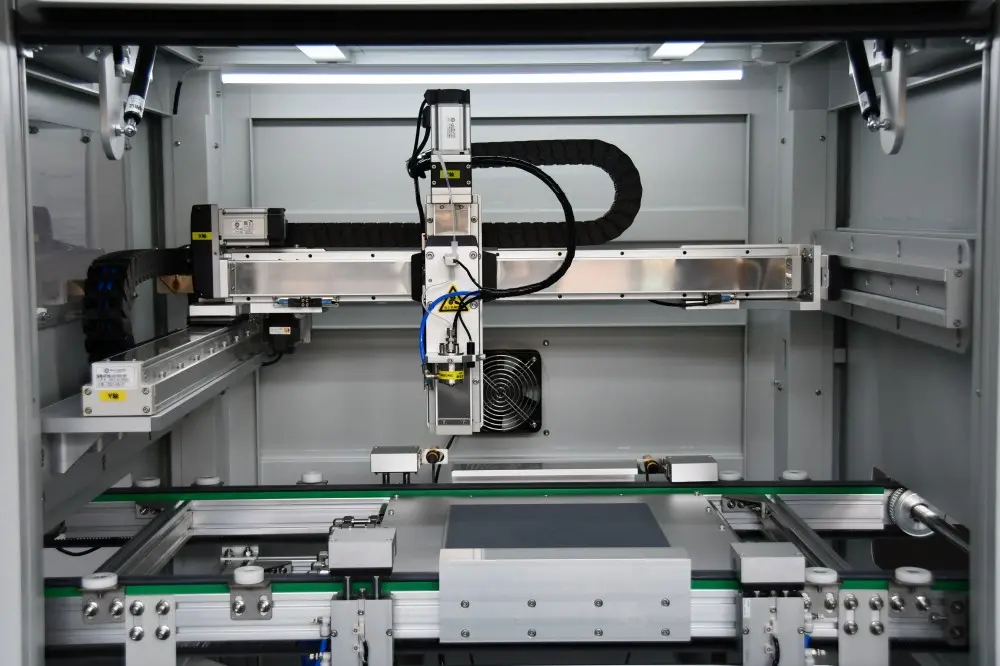

4. Motion system: XYZ three-axis imported servo motor+fully enclosed precision screw module+horizontal automatic conveying mechanism

5. Operating system: PLC control, full-color touch screen, operation control system developed based on Windows system, supporting remote operation, upgrade, etc.

-

Optional Configuration

1. Ultrasonic dispersion system: 40Khz 100w, 25ml (50ml, 75ml, 100ml optional) biological grade sampler

2. Heating and drying platform: High quality stainless steel electric heating coils and digital controllers are used, with high precision. The platform material is available in aluminum alloy small holes and ceramic small holes

3. Vacuum adsorption platform: equipped with an internal vacuum generator to achieve vacuum negative pressure

4. Input voltage: 220V or 380V, 50-60Hz

5. Laser positioning device: Use laser to quickly locate the spraying position.

We can also customize other configurations according to your needs.

Product Application

1. Coating on the center console

The use of ultrasonic spraying technology for coating treatment on the center console has achieved a uniform matte surface, enhanced wear resistance and stain resistance, and improved the overall visual effect.

2. Door panel decoration

Applying ultrasonic coating on the door panels of a luxury SUV enhances the luxurious feel of the interior and reduces production costs through different coating effects, such as metallic texture and leather texture.

3. Seat fabric protection

Adding ultrasonic coating to its seat fabric provides excellent anti fouling and waterproof performance, making the seat easier to clean and maintain, and extending its service life.

4. Interior of the car roof

The use of ultrasonic spraying on the roof interior not only provides an elegant appearance, but also improves acoustic performance and reduces interior noise.

5. Door handle

Ultrasonic coating treatment was applied to the door handle, which increased its scratch resistance, maintained the appearance of the handle, and improved its tactile feel.

6. Dashboard coating

The dashboard is coated with ultrasonic waves, which provide anti reflection performance, ensuring clear and readable screens in sunlight while enhancing durability.