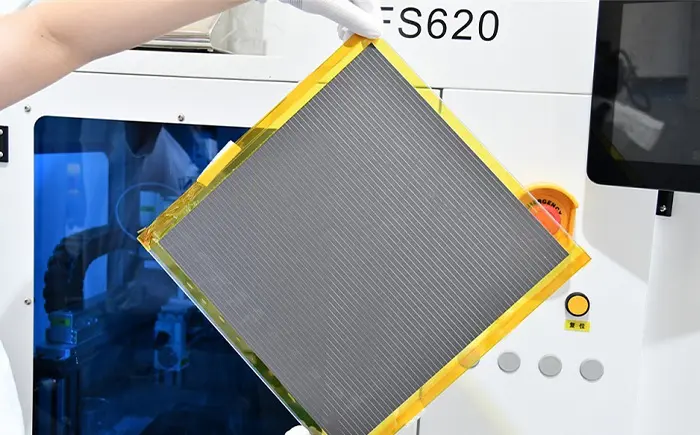

Floor Standing Ultrasonic Coating System FS650

Advantage

Product Configuration

-

Conventional Arrangement

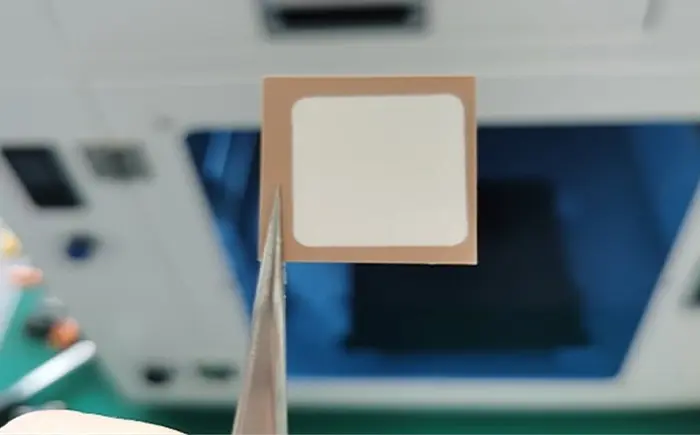

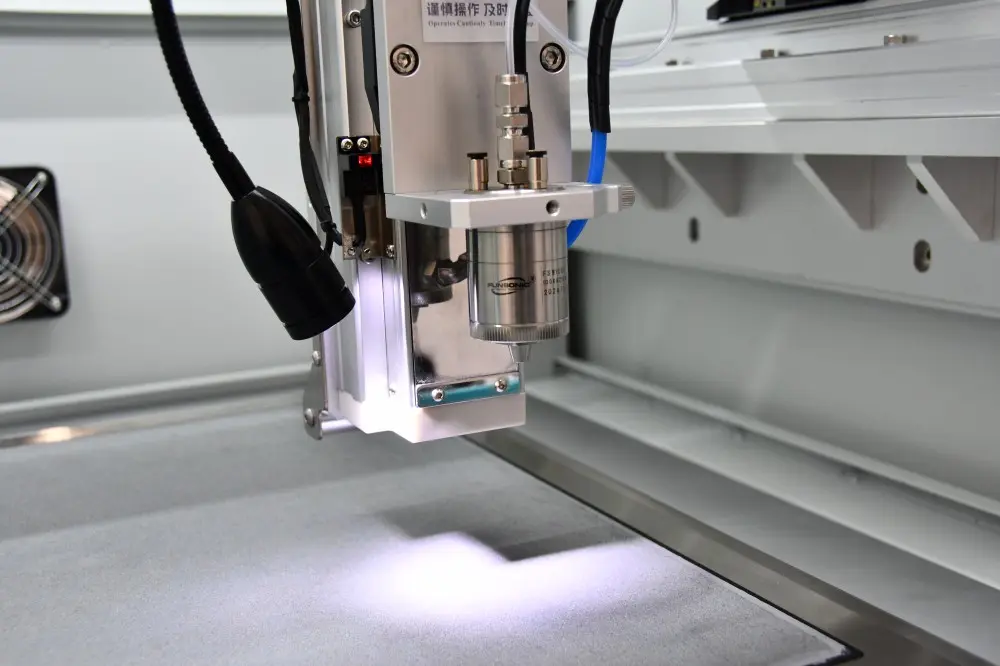

1. Ultrasonic atomizing nozzle: a high-frequency nozzle suitable for various solutions

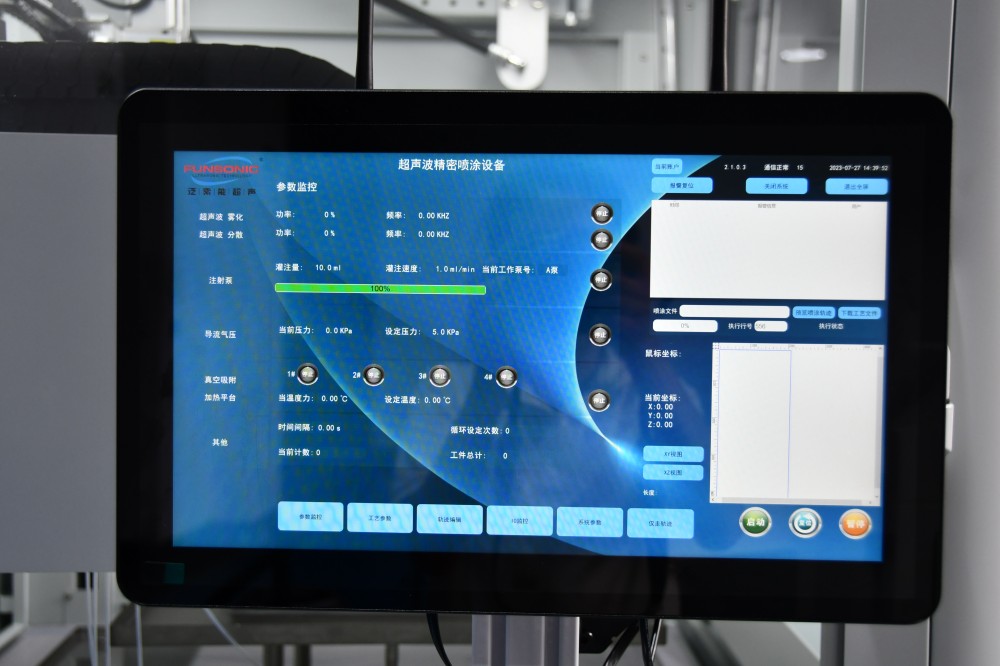

2. Ultrasonic generator: LCD intelligent CNC

3. Liquid supply equipment: precision injection pump+biological grade sampler, liquid supply accuracy of 0.1 μ L/min

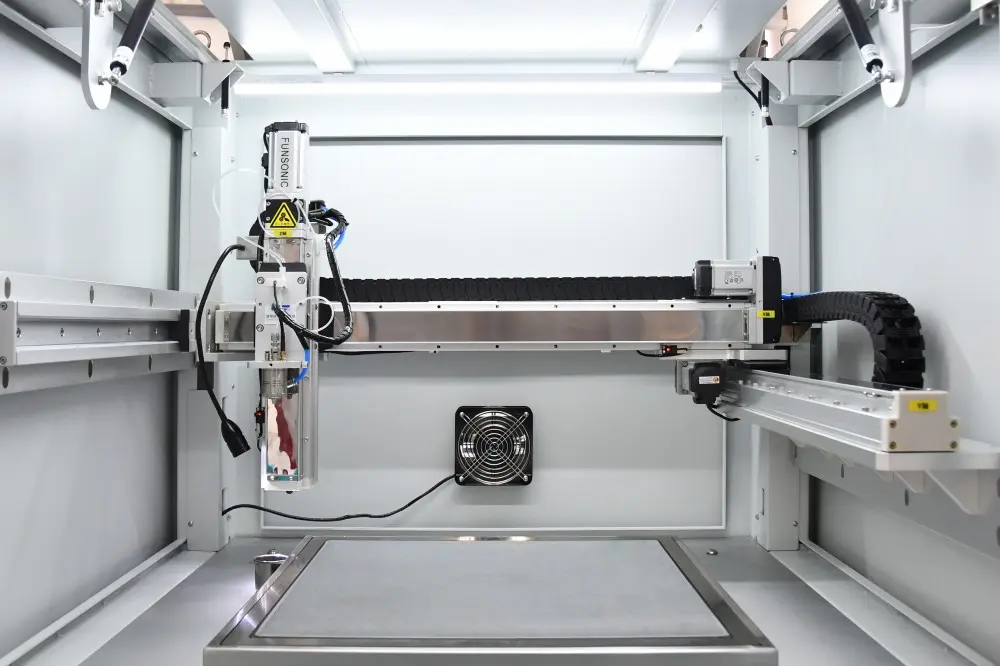

4. Motion system: XYZ three-axis imported servo motion system, R-axis nozzle rotation mechanism

5. Operating System: Equipped with FUNSONIC's control system specially developed for ultrasonic spraying, the operation is fast and easy to use. It can integrate functions such as ultrasonic atomization, ultrasonic dispersion, injection pump, guide gas, heating table, and vacuum adsorption plate, including one click generation of commonly used template trajectories and editing of complex G-code trajectories.

-

Optional Configuration

1. Ultrasonic dispersion: The 40K ultrasonic dispersion system is embedded in the sampler and uses the ultrasonic vibration effect to perform fine or ultra-fine ultrasonic grinding on solids or fluids.

2. Heating and drying platform: Aluminum alloy small hole heating plate, with a maximum heating temperature of 300 ℃, suitable for thin plate substrates; Micro porous ceramic precision heating plate, capable of heating up to 150 ℃, suitable for thin film substrates

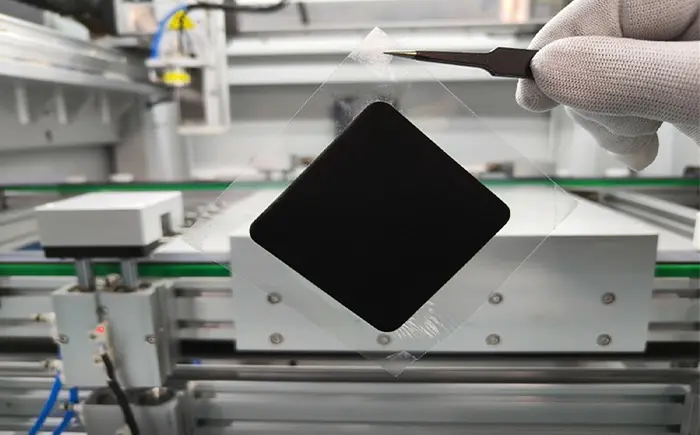

3. Vacuum adsorption platform: equipped with multiple vacuum generators, which can be controlled by zones, accurately adsorb film substrates without deformation.

4. Laser positioning: Use a laser to quickly align the material spraying position.

5. Other configurations: Footmaster casters, thricolored Indicator lights, raw material storage

We can also customize other configurations according to your needs.

Product Application

1. Glass: Suitable for manufacturing transparent conductive films, widely used in touch screens and optoelectronic devices.

2. Ceramics: In the fields of electronic components and catalysts, ceramic substrates can provide good chemical stability and high temperature resistance.

3. Metal: Metal substrates (such as aluminum, copper, etc.) can be used for electrical connections and deposition of conductive films.

4. Semiconductors: Semiconductor materials such as silicon and germanium are suitable for thin film deposition in microelectronic devices to ensure excellent electrical performance.

5. Polymers: Some polymer substrates can withstand low-temperature deposition and are suitable for the preparation of flexible electronic devices.

6. Composite materials: Composite substrates can be used for applications that require lightweight and high strength, such as the aerospace and automotive industries.

7. Film materials: Suitable for surface modification and functionalization of other existing film materials.

8. Optical materials: Optical materials with good transparency can be used for the deposition of optical films, improving transparency and anti reflection performance.

9. Biomaterials: Suitable for the deposition of biocompatible coatings in biomedical applications.