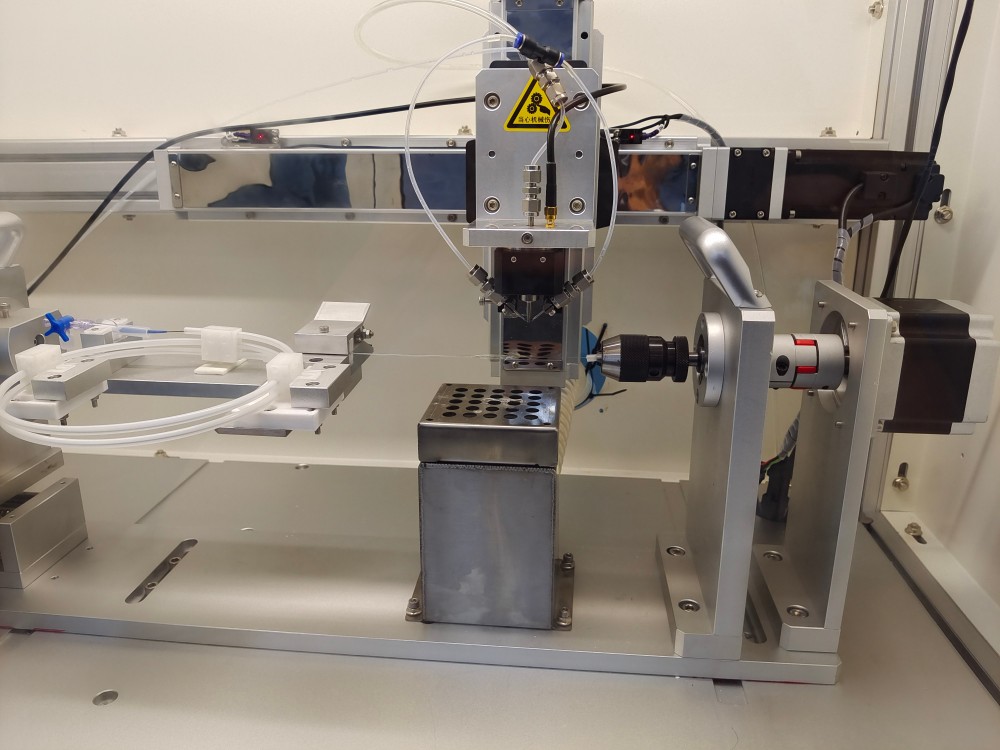

Floor Standing Ultrasonic Balloon Catheter Coating System FS1005

Advantage

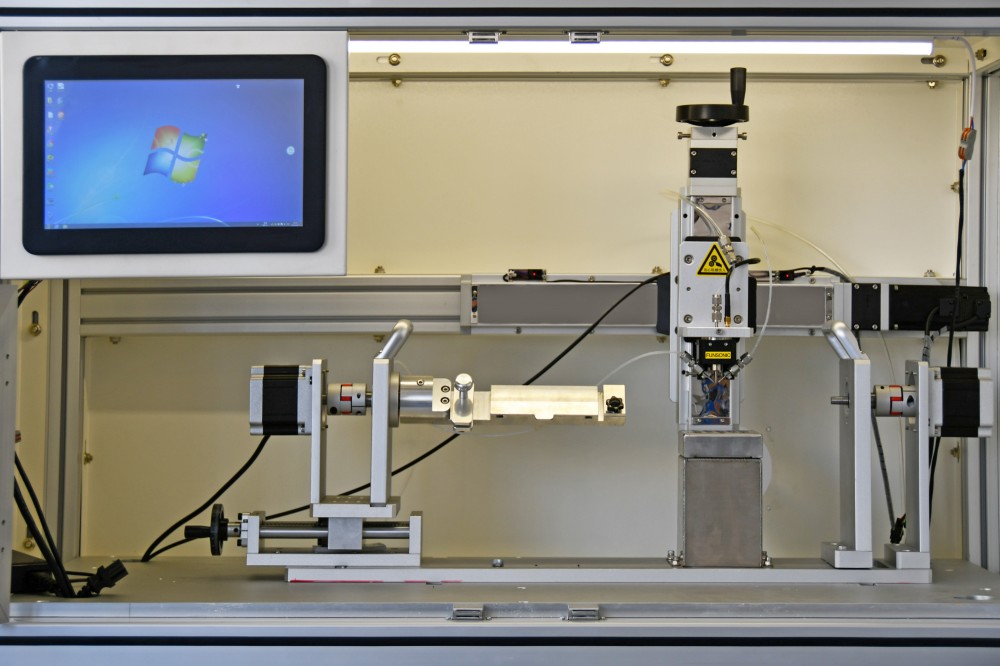

Product Configuration

-

Conventional Arrangement

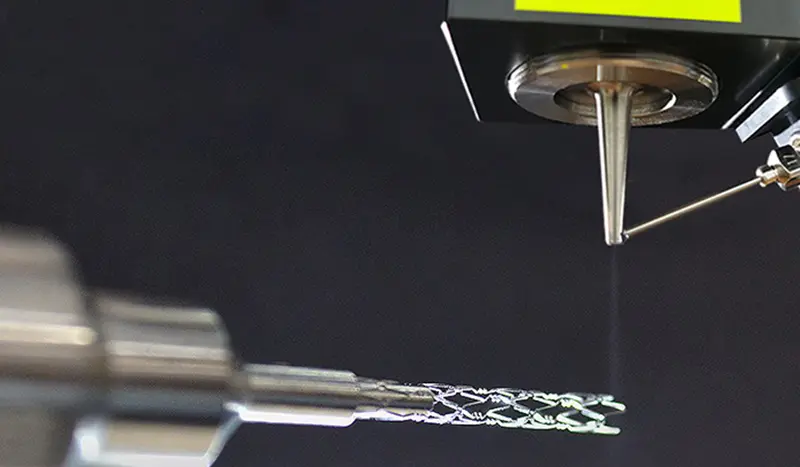

1. Ultrasonic nozzle: optional 20-200Khz multiple nozzle systems

2. Ultrasonic power supply: fully CNC precision power supply, fully intelligent frequency following, frequency tracking, stable performance

3. Liquid supply equipment: precision injection pump+biological grade sampler, liquid supply accuracy of 0.1 μ L/min

4. Sports system: XYZ three-axis imported servo motor+fully enclosed precision screw module

5. Operating System: Based on the Windows system, FUNSONIC independently developed a spraying control system, PLC control, and full-color touch screen

-

Optional Configuration

1. Ultrasonic dispersion liquid supply system: During the spraying process, it can continuously disperse and stir nanoparticles, effectively reducing the precipitation phenomenon of the spraying liquid and greatly improving the uniformity of the film layer

2. Bracket installation positioning, customized according to customer requirements

3. Action trajectory can be customized

4. Can be replaced for stent spraying and balloon catheter spraying

We can also customize other configurations according to your needs.

Product Application

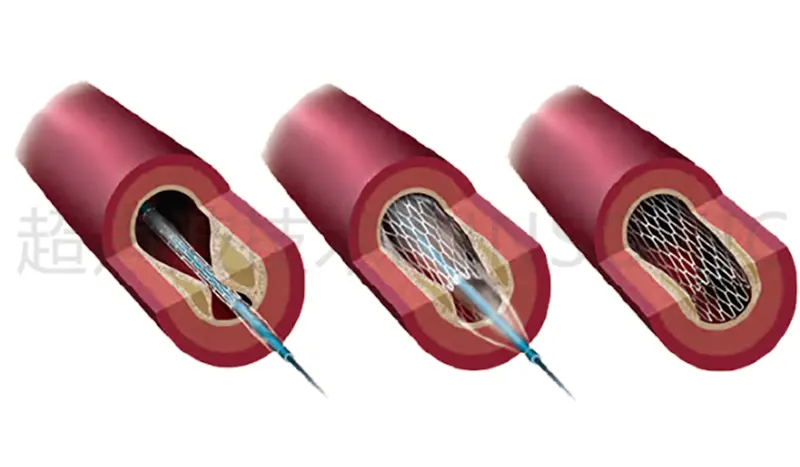

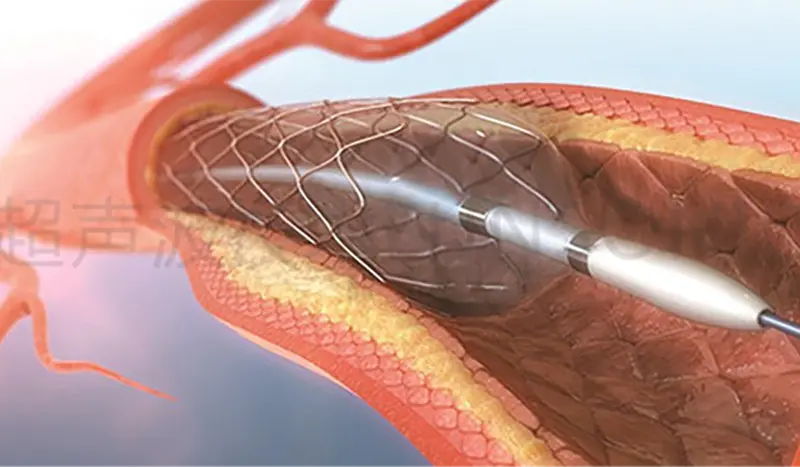

1. Vascular stent: Used for coating stents in coronary arteries, peripheral arteries, etc., to improve biocompatibility and antithrombotic performance.

2. Catheter: Enhance the wear resistance and reduce friction of the catheter.

Ultrasonic balloon catheter stent spraying is the process of applying antiplatelet drugs, anti-inflammatory drugs, or biomaterials onto the surface of a balloon catheter or stent through ultrasonic atomization, in order to control thrombus formation and reduce the risk of restenosis. This spraying method greatly improves the compatibility between the scaffold material and biological tissue, reduces rejection reactions, and enhances its therapeutic effect.