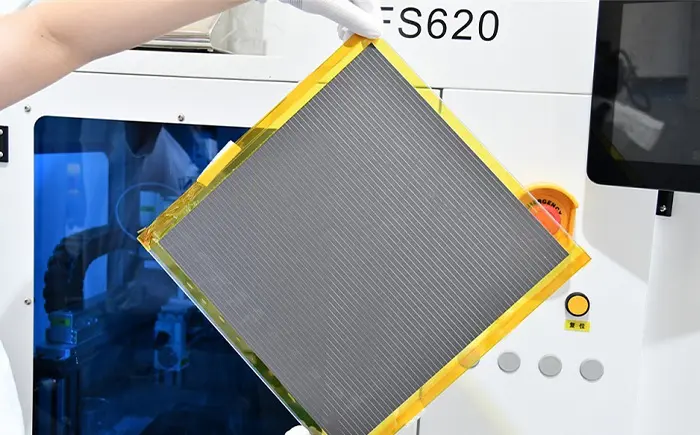

Floor Standing Ultrasonic Automatic Flip Coating System FS650Y

Advantage

Product Configuration

-

Conventional Arrangement

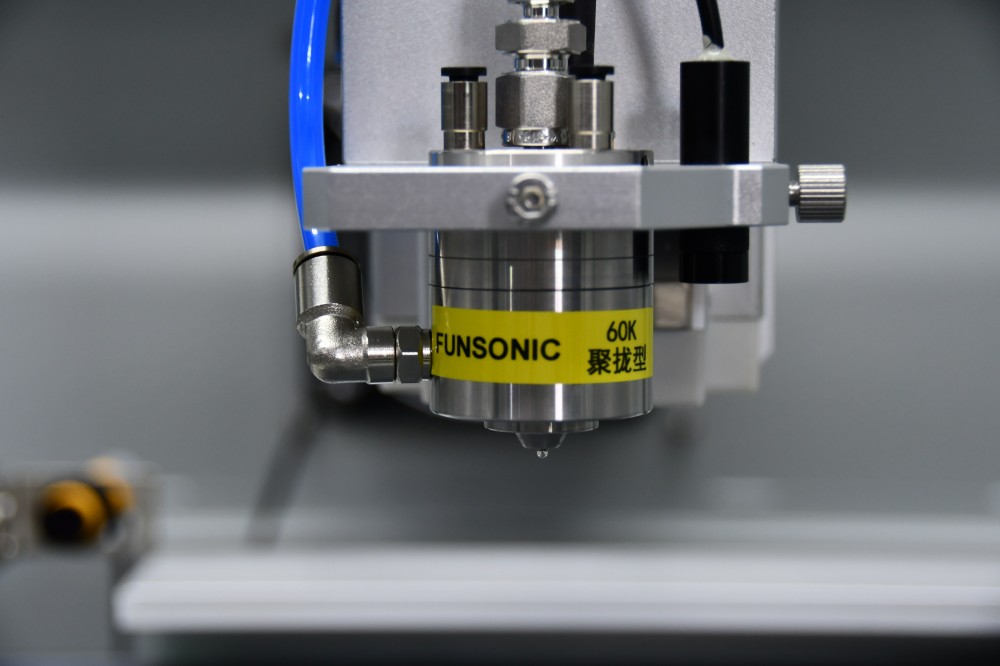

1. Ultrasonic nozzle: 20Khz-200kHz (commonly used 60K, 100K)

2. Ultrasonic power supply: Digital

3. Liquid supply equipment: precision injection pump+biological grade sampler, (self pumping, constant flow optional)

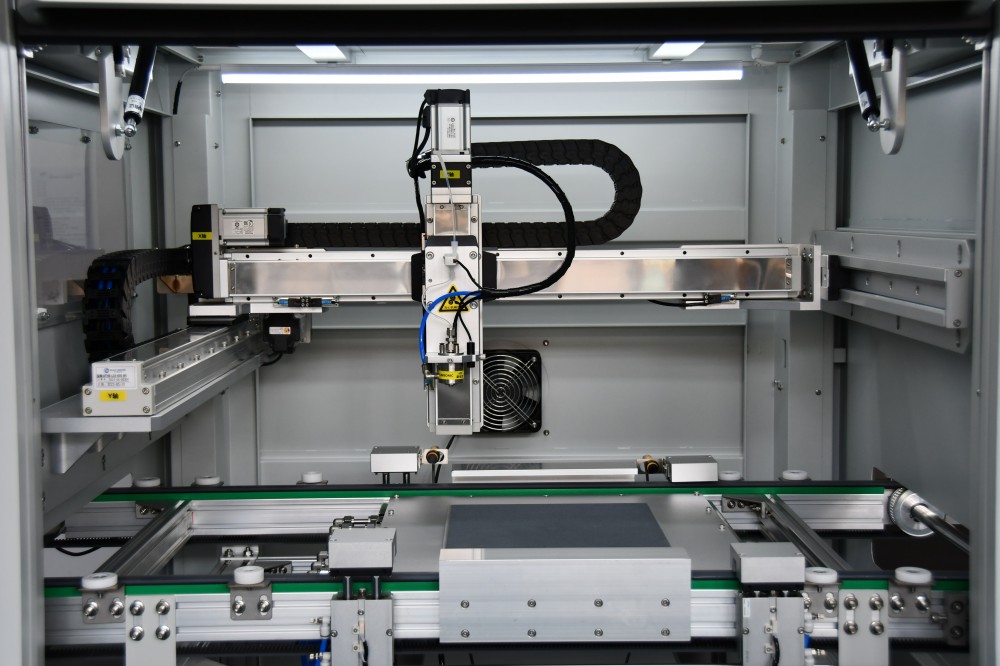

4. Motion system: XYZ three-axis imported servo motor+fully enclosed precision screw module+horizontal automatic conveying mechanism+automatic flipping machine

5. Motion system: XYZ three-axis imported servo motor+fully enclosed precision screw module+horizontal automatic conveying mechanism+automatic flipping machine

-

Optional Configuration

1. Ultrasonic dispersion liquid supply system: It can continuously disperse and stir nanoparticles during the spraying process, effectively reducing the precipitation phenomenon of the spraying liquid and greatly improving the uniformity of the film layer

2. Heating and drying platform: using aviation aluminum porous platform or precision microporous ceramic platform, precise temperature control of 200 ℃ (higher heating temperature can be customized)

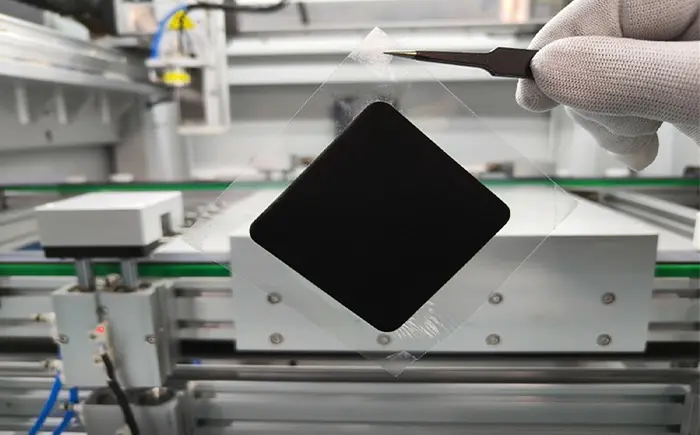

3. Vacuum adsorption platform: equipped with multiple vacuum generators, can be controlled by zones, and accurately adsorbs film substrates without deformation.

4. Nozzle alignment device: using laser alignment to quickly align the material spraying position.

We can also customize other configurations according to your needs.

Product Application

1. Spray coating of smartphone casing

Application: The coating of the mobile phone shell adopts ultrasonic spraying technology to achieve uniform coating thickness and delicate spraying effect, ensuring a beautiful appearance while providing waterproof and anti fingerprint functions.

2. Protection of electronic components

Application: Circuit board coating, using ultrasonic spraying technology, spraying special protective coatings to prevent moisture and corrosion, improving the durability of the circuit board, extending its service life, and reducing the failure rate caused by environmental factors

3. Coating for household appliances

Application: Spray coating of washing machine shell, using ultrasonic spraying technology and environmentally friendly coatings, achieving a wear-resistant and waterproof surface treatment effect, improving the durability and cleanliness of the washing machine shell, while reducing coating waste in the production process and lowering costs.

4. Coating for LED lighting fixtures

Application: Surface treatment of LED lamps, using ultrasonic spraying technology to spray transparent protective coatings, improving the light transmittance and wear resistance of the lamps.

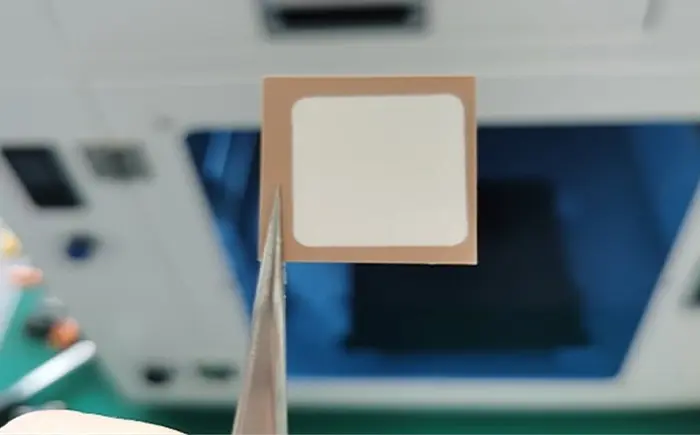

5. Surface treatment of medical devices

Application: Antibacterial coating on the surface of medical devices, using ultrasonic spraying technology to spray coatings with antibacterial functions, meeting strict hygiene standards and antibacterial requirements, significantly reducing the risk of bacterial growth on the surface of the devices.