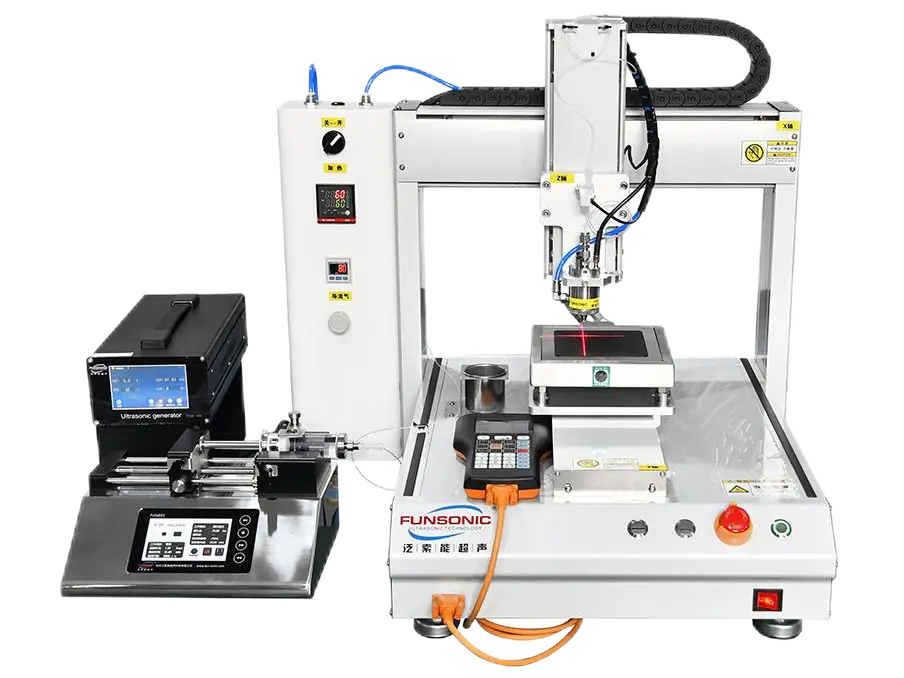

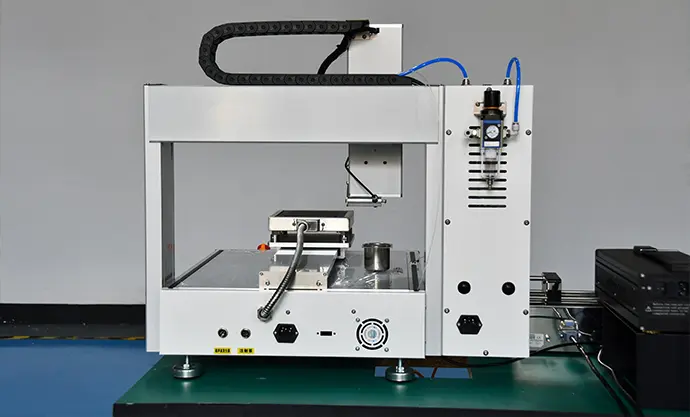

Entry-Level Ultrasonic Spray Coating Machine FS150

Advantage

Product Configuration

-

Conventional Arrangement

1. Ultrasonic high-frequency low-pressure nozzle: 20-200Khz

2. Ultrasonic power supply: fully CNC, automatic frequency tracking

3. Liquid supply system: precision injection pump+biological grade sampler

4. Sports system: XYZ three-axis+can move up and down/forward and backward/left and right

5. Control method: The handheld box adopts a 320 * 240 high-resolution color screen motion control interface+physical buttons

-

Optional Configuration

1. Ultrasonic dispersion system: embed a 40Khz ultrasonic transducer into the sample injector to effectively avoid sedimentation and agglomeration during the transportation of the suspension

2. Heating platform: equipped with high-quality stainless steel electric heating coils, using aviation aluminum or microporous ceramics as substrates, for fast and effective drying treatment according to different applications

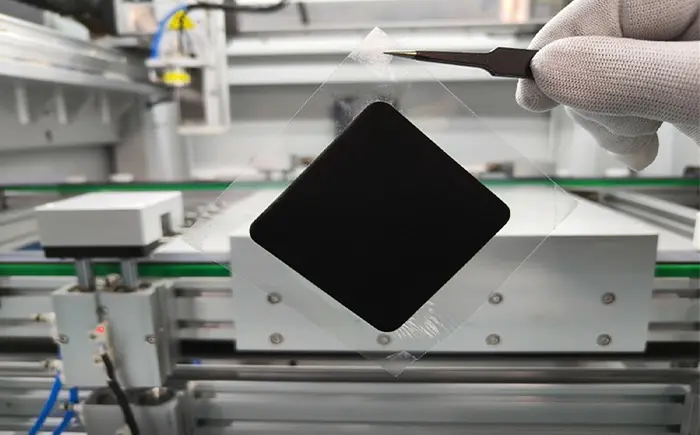

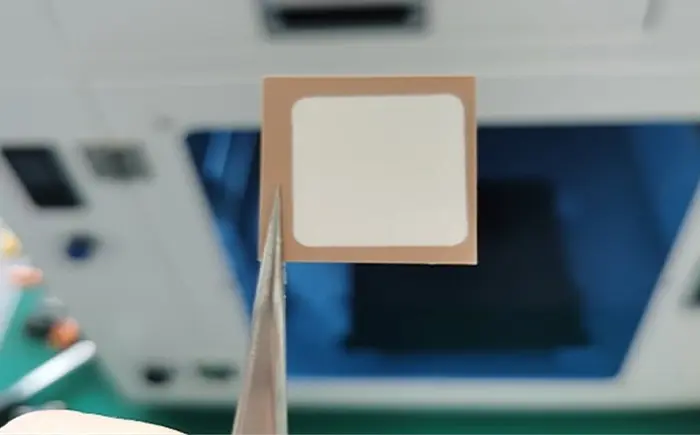

3. Vacuum adsorption platform: Under negative pressure inside the cavity, the small circular holes on the surface of the substrate have the function of adsorbing flat thin film products

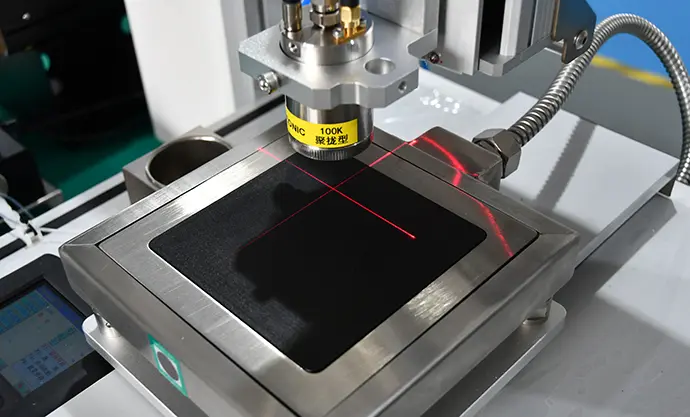

4. Laser positioning device: Use laser positioning to quickly lock the material spraying position.

We can also customize other configurations according to your needs.

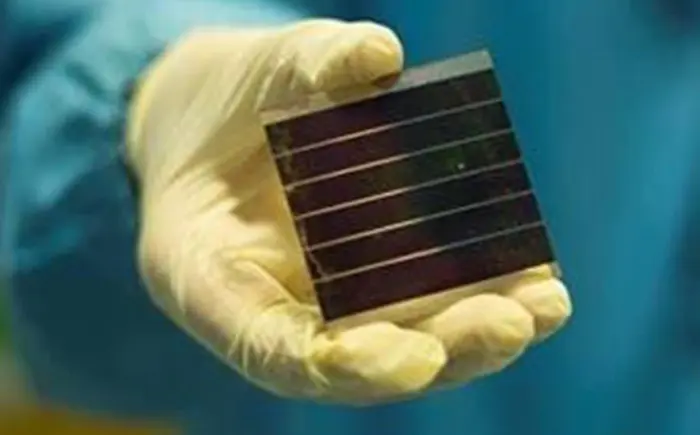

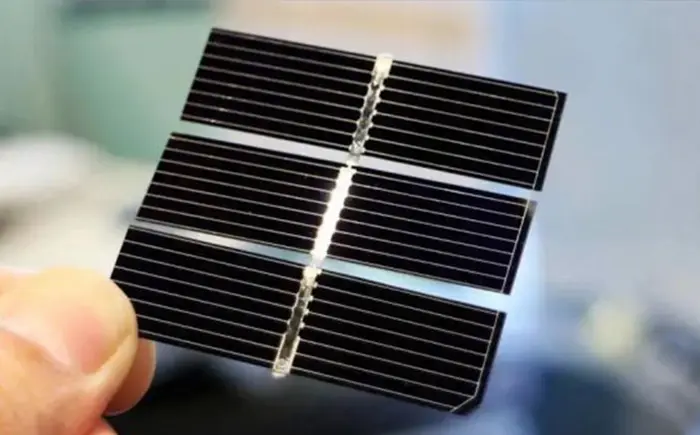

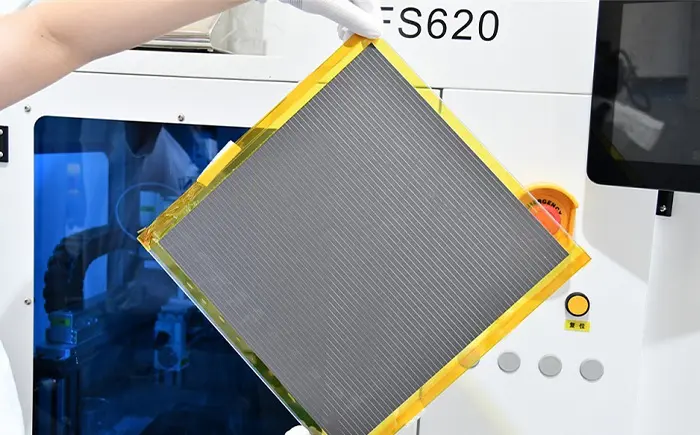

Product Application

2. Automotive industry: used as a coating for high-temperature parts such as engine components and exhaust systems.

3. Aerospace: Protect critical components from the effects of extreme temperatures and environments.