Ultrasonic Balloon Catheter Stent Spraying

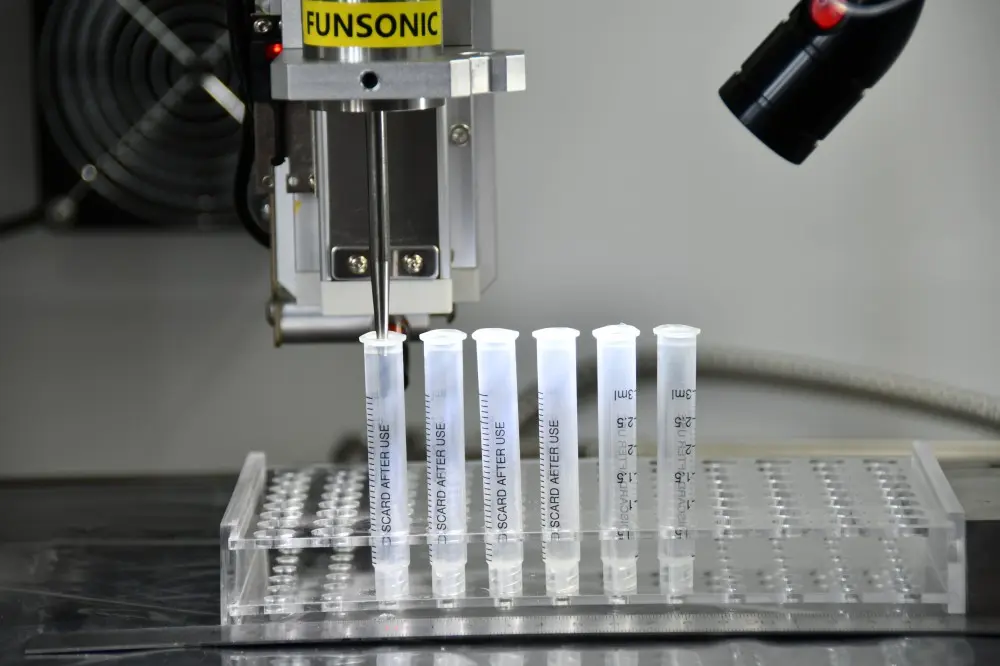

Ultrasonic Injection Tube Spraying

Ultrasonic injection tube spraying adopts ultrasonic atomization nozzle technology. With an extended nozzle front end design, the ultrasonic nozzle can penetrate into narrow spaces for spraying, mainly used for spraying on the inner wall of pipelines.

The common application is to spray the silica coating to accelerate coagulation. The silica slurry decomposes any silica aggregates through the vibration of the long nozzle nozzle, and sprays the atomized spray onto the wall of the coating area at the bottom of the BCT or syringe cylinder, rather than coating the entire tube, to control the coating position more accurately.

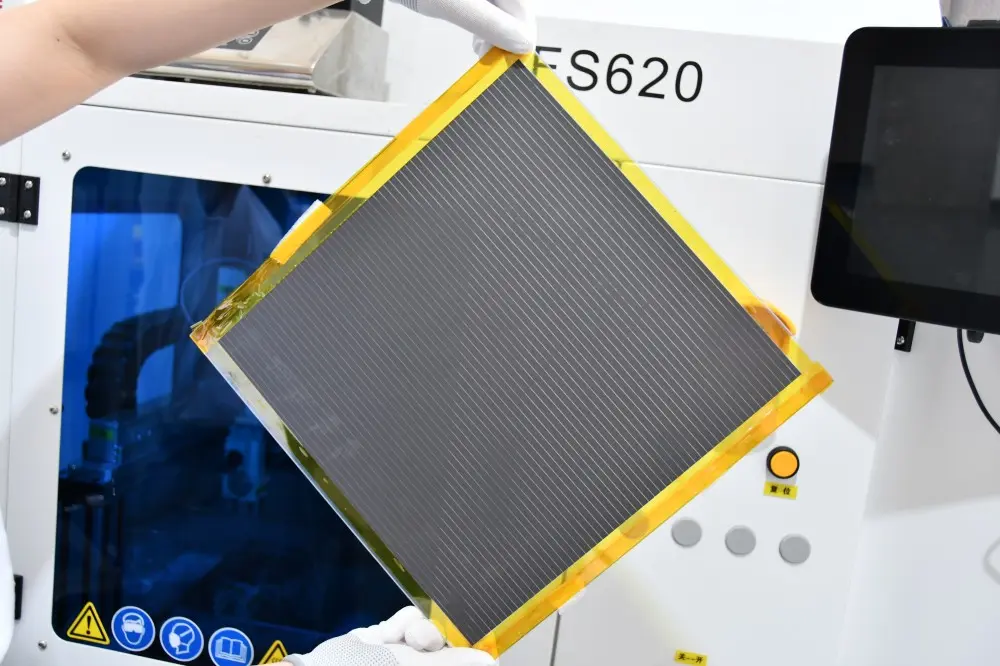

Ultrasonic Fuel Cell Catalyst Coating

Ultrasonic fuel cell catalyst coating system is an emerging technology used to manufacture efficient and durable fuel cells. Ultrasonic fuel cell technology can ensure that the catalyst material forms a uniform coating on the electrode surface, thereby improving the utilization rate of active sites.

The coating under the action of ultrasound can enhance the corrosion resistance of electrode materials, improve the service life of fuel cells, and ensure stable electrochemical performance of fuel cells during long-term operation.

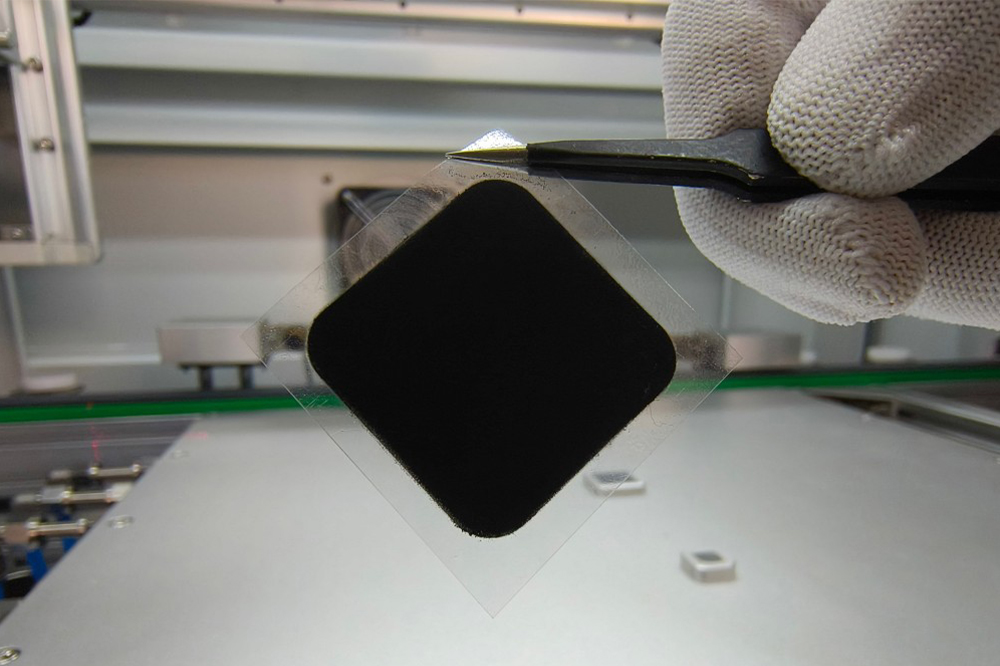

Ultrasonic Anion Membrane Spraying

Ultrasonic Anion membrane spraying technology uses the vibration energy of ultrasound, which is an advanced surface treatment technology. It uses the vibration energy of ultrasound to evenly spray the coating in the form of small droplets on the surface of the workpiece, making the bonding between the coating and the workpiece surface tighter, with stronger adhesion, and improving the durability and corrosion resistance of the coating.