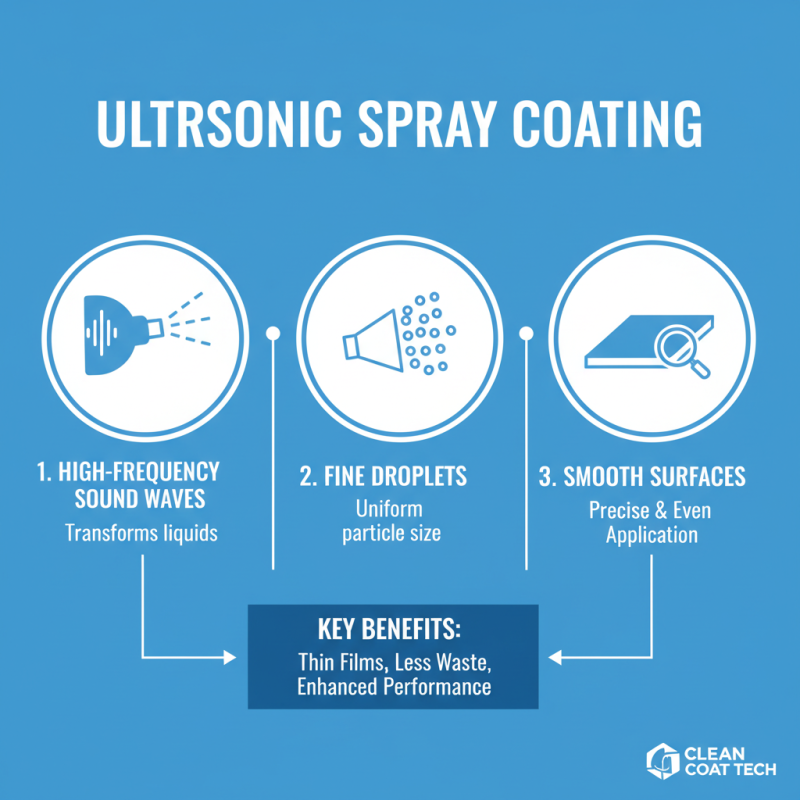

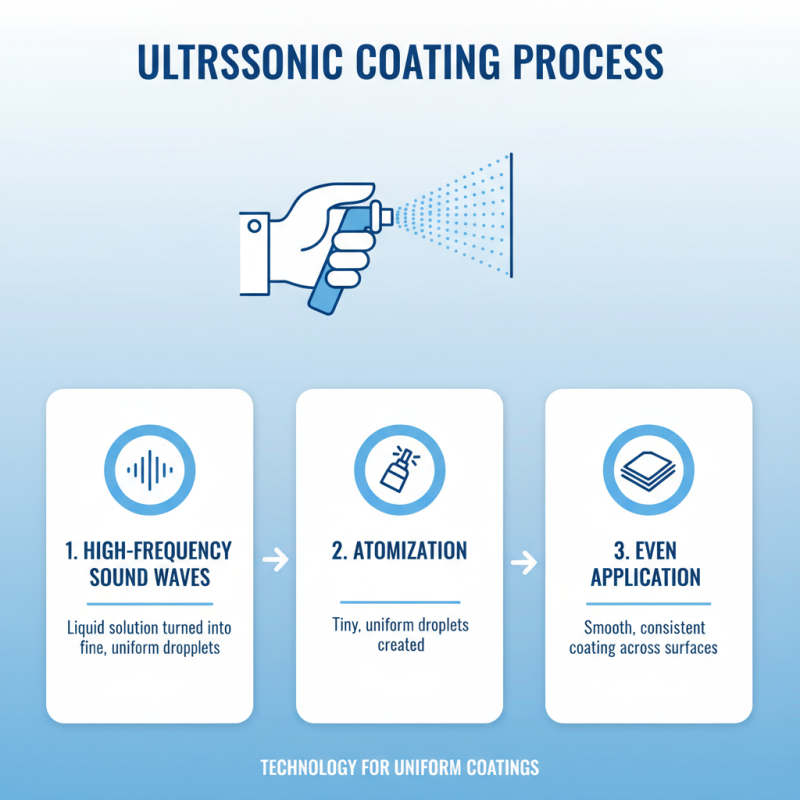

An Ultrasonic Spray Coater is a sophisticated tool in the coating industry. This technology uses high-frequency ultrasonic waves to transform liquid into fine droplets. These droplets then uniformly coat surfaces, ensuring an even layer.

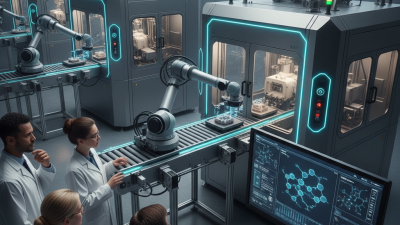

Dr. Emily Carter, a leading expert in spray coating technology, states, “Ultrasonic spray coating revolutionizes surface treatments.” Her insights emphasize the importance of precision in coating applications. The Ultrasonic Spray Coater offers advantages like reduced waste and improved coverage.

However, the technology is not without its challenges. Mastering the settings can be tricky. Variables like viscosity and flow rate significantly impact results. Users often face a learning curve. Still, with practice, they can unlock the full potential of this innovative equipment. The Ultrasonic Spray Coater stands at the forefront of modern coating solutions.

An ultrasonic spray coater is a device used for applying thin films of liquid onto surfaces through ultrasonic atomization. This technology employs high-frequency sound waves to create fine droplets of liquid, allowing for precise and uniform coating results. The process begins with a liquid being fed into a nozzle. As the liquid flows, ultrasonic vibrations break it into tiny droplets. These droplets are then propelled toward the target surface.

The applications for ultrasonic spray coating are diverse. Industries like electronics, healthcare, and automotive utilize it for coatings, paints, and even medical substances. The ability to control droplet size and pattern is crucial for achieving the desired thickness. However, achieving perfect uniformity can be challenging. Factors like liquid viscosity, nozzle design, and flow rate need careful adjustment.

Sometimes, operators notice inconsistent coating results. This might stem from fluctuating parameters or equipment wear. Regular maintenance and testing help identify such issues, but achieving perfection remains a trial-and-error process. Still, practitioners must embrace ongoing experimentation to refine their techniques and improve outcomes. The learning journey is just as important as the final product.

Ultrasonic spray coating technology is revolutionizing several industries, from electronics to automotive. This method uses ultrasonic waves to create fine mist patterns. These patterns ensure an even coating of materials. Reports indicate that this technology increases material efficiency by up to 40%. The precision of ultrasonic spray coating minimizes waste, which is crucial for cost management in manufacturing.

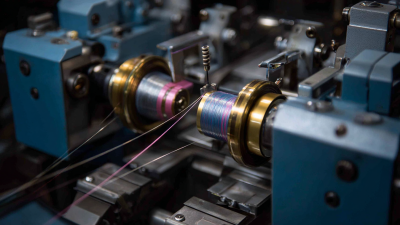

One key principle is the atomization process. Ultrasonic transducers convert electrical energy into mechanical energy. This process breaks liquid into tiny droplets. The size of the droplets can range from 10 to 100 microns. Smaller droplets lead to better coverage and adherence. Many manufacturers are adopting this technology for its high yield and reduced environmental impact.

Ultrasonic spray coaters use high-frequency sound waves. These devices transform liquid coatings into fine droplets. They are essential for achieving uniform and smooth surfaces.

Key components include the ultrasonic atomizer, liquid reservoir, and nozzle. The atomizer generates ultrasonic waves. These waves create high-frequency vibrations, breaking liquid into tiny droplets. The liquid reservoir holds the coating material, ensuring a steady flow. The nozzle allows for even distribution.

Tips: Ensure the liquid is well-mixed. Poorly mixed coatings can lead to faulty application. Regular maintenance of the nozzle is crucial. A clogged nozzle results in inconsistent spray patterns.

Another important part is the control system. It regulates the spray parameters like flow rate and frequency. Incorrect settings can lead to subpar results. Experiment with different settings to find the best match for your materials. Keep in mind that every coating has unique properties. It may take time to perfect the application process.

The ultrasonic coating process is a fascinating technology. It uses high-frequency sound waves to turn a liquid solution into tiny droplets. These droplets are incredibly fine and uniform, which makes the coating even across surfaces. This method ensures a smooth and consistent application.

During the process, the ultrasonic spray coater generates a mist. This mist is directed onto the target surface. The coating material adheres effectively thanks to its small droplet size. However, sometimes the application can be uneven. Factors such as liquid viscosity and temperature can affect the final result.

Though ultrasonic spray coating is efficient, challenges remain. For instance, achieving the right droplet size requires precise control. If the parameters are not set correctly, the quality of the coating can vary. Operators must pay close attention to setup and calibration. Reflection on these aspects can lead to better results and less waste.

Ultrasonic spray coating is revolutionizing various industries. This technology offers precise control and uniform application of coatings. It has been proven to enhance efficiency in sectors like pharmaceuticals, automotive, and electronics. According to recent industry reports, the ultrasonic spray coating market is anticipated to reach $3.5 billion by 2025, driven by its benefits in reducing material waste and improving coating quality.

One major application is in the pharmaceutical industry, where it provides uniform drug delivery coatings. This consistency can significantly increase the effectiveness of medications. Additionally, in electronics, ultrasonic spray coating enables the creation of thinner, more uniform layers of conductive materials. However, challenges remain. Operators must ensure that the ultrasonic parameters are correctly set. If not, this could lead to uneven coatings. Many manufacturers still struggle with these adjustments.

The reduced material waste is another area of interest. Traditional spray methods can waste up to 50% of coatings. Ultrasonic techniques can cut this waste down to about 10%. Yet, the equipment cost remains a concern for smaller companies. They may find the initial investment daunting. Balancing these considerations is essential for widespread adoption. The technology holds promise, but it requires careful planning and execution.