In the ever-evolving field of materials processing, Ultrasonic Dispersion Equipment has emerged as a crucial component for enhancing mixing efficiency across various industries. According to a recent report from the International Society for Ultrasonics, the market for ultrasonic dispersion equipment is expected to grow by 15% annually through 2025, fueled by increasing demand for high-performance mixing in sectors such as pharmaceuticals, food and beverage, and chemicals. As industries strive for superior product quality and consistency, the efficiency and precision of ultrasonic dispersion techniques become paramount.

Dr. Emily Henderson, a renowned expert in the field of ultrasonic technology, emphasizes the importance of adopting advanced ultrasonic dispersion methods: "The integration of ultrasonic dispersion equipment not only optimizes particle size and distribution but also significantly reduces processing times, leading to a marked increase in overall productivity." This trend reflects a growing recognition of ultrasonic technology’s ability to enhance product characteristics while minimizing resource consumption, an essential consideration as companies aim for more sustainable practices.

As we delve into the "Top 5 Ultrasonic Dispersion Equipment for Enhanced Mixing Efficiency," we highlight equipment that exemplifies these advancements, showcasing how they can revolutionize mixing processes and drive operational excellence.

Ultrasonic dispersion equipment has revolutionized the way industries achieve enhanced mixing efficiency. By utilizing high-frequency sound waves, these devices facilitate the breakdown of particles and the thorough mixing of materials, leading to superior results in various applications, from pharmaceutical to food processing. The efficacy of ultrasonic dispersion lies in its ability to create intense shear forces that effectively disperse and homogenize mixtures, resulting in a uniform product with improved properties.

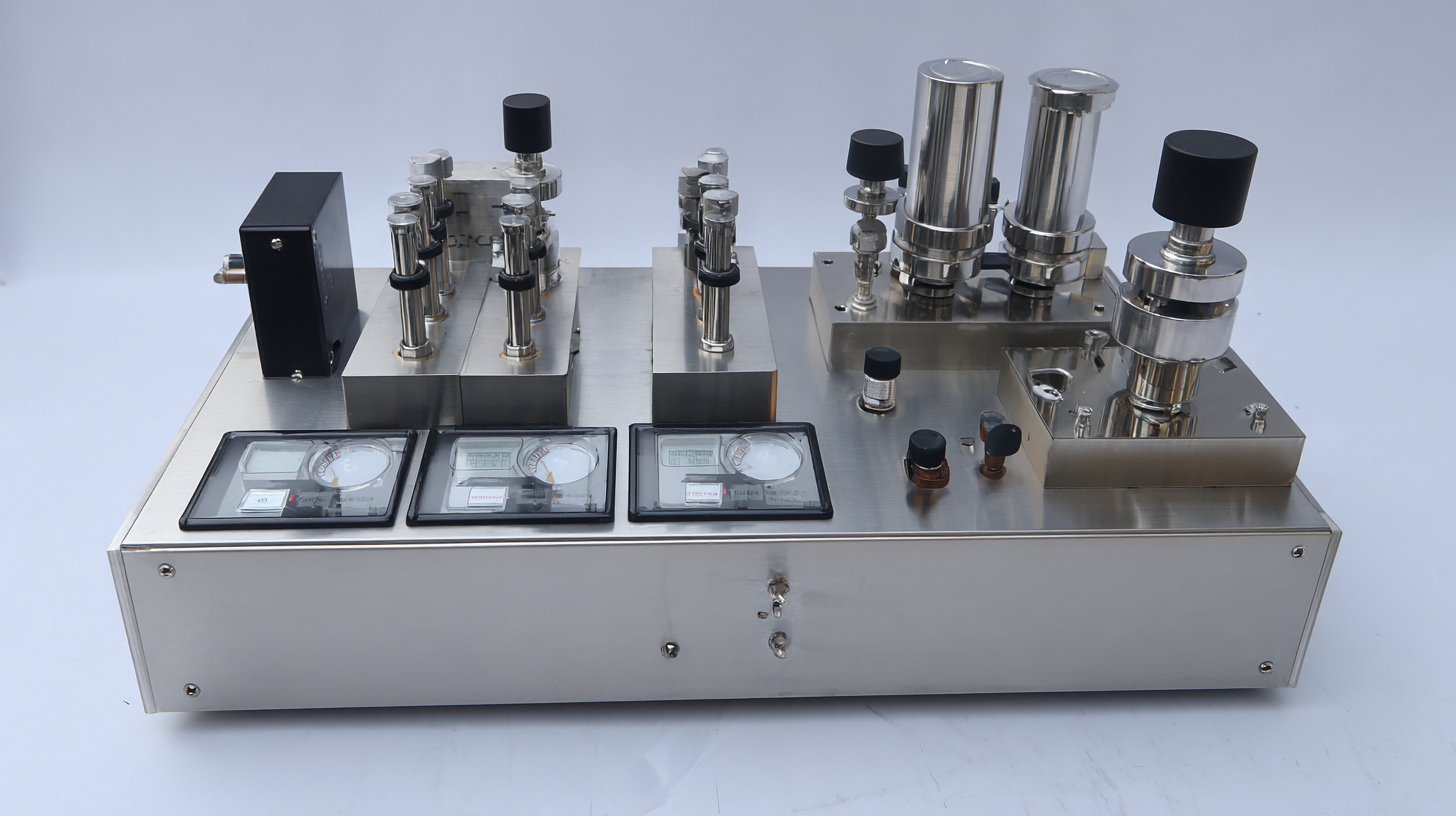

The leading ultrasonic dispersers on the market are designed to optimize the mixing process further. Features such as adjustable frequency and amplitude allow operators to tailor the ultrasonic energy to suit the specific requirements of their materials. This adaptability is crucial for achieving superior mixing results, as it ensures that even the most challenging formulations can be successfully processed. Furthermore, innovations in sonication technology, including continuous flow systems and advanced control interfaces, have made these systems more efficient, ensuring consistent results in production environments.

When selecting ultrasonic dispersion machines for enhanced mixing efficiency, it is crucial to consider several key features that can significantly impact performance. One of the foremost attributes is the frequency range of the ultrasonic waves. Higher frequencies can generate finer dispersions and facilitate better mixing, making it essential to choose machines that operate optimally within the required frequency range. Moreover, the power output of the device is also critical; machines with adjustable power settings allow for versatile applications, accommodating different materials and desired mixing outcomes.

In recent advancements, ultrasonic technology has shown promise beyond traditional mixing applications. For instance, new ultrasonic devices developed by engineers can harvest water from the atmosphere at an efficiency 45 times greater than standard methods, utilizing sound waves to extract moisture rapidly from sorbent materials. This innovation not only highlights the versatility of ultrasonic equipment in various industries but also underscores its potential in addressing urgent needs such as clean water accessibility. The implications of such technologies, coupled with precise control over mixing and dispersion, could significantly enhance efficiency across the board, making it vital for industries to invest in cutting-edge ultrasonic dispersion machinery.

The comparative analysis of leading ultrasonic dispersion technologies highlights the significant advancements in mixing efficiency and material solubilization through the application of power ultrasound. Recent studies have demonstrated the efficacy of power ultrasound in solubilizing bovine gelatin without heating, indicating its potential for energy-efficient processes in food and pharmaceutical applications. This method not only accelerates the dispersion process but also preserves the functional properties of sensitive compounds, making it an attractive choice for manufacturers.

Additionally, the utilization of ultrasonication in wastewater treatment facilities has shown promising results in controlling bulking and foaming. A case study in Morelos, Mexico, compared low-frequency ultrasound and UV radiation technologies, revealing that ultrasonication can effectively reduce foaming issues, thereby enhancing the treatment efficacy and operational stability of wastewater systems. This underscores the versatility of ultrasonic dispersion technologies in diverse industrial settings, providing substantial benefits over conventional methods and emphasizing the importance of continuous technology evaluation to optimize mixing and dispersion processes across various applications.

Ultrasonic dispersion equipment has gained considerable traction across various industries due to its enhanced mixing efficiency and ability to produce homogeneous blends at a microscopic level. In the pharmaceutical sector, ultrasound technology is employed to improve the bioavailability of drugs. According to a report by MarketsandMarkets, the global ultrasonic homogenizers market is expected to reach $540 million by 2026, driven primarily by its applications in drug formulation and the development of nanomaterials. This technique allows for better dispersal of active ingredients, leading to more effective therapies and reduced side effects.

The food and beverage industry also benefits significantly from ultrasonic dispersion equipment. The application of ultrasonic waves can enhance the emulsification of oils in products like sauces and dressings, ensuring consistent texture and flavor. A study in the Journal of Food Engineering highlighted that ultrasonic processing could improve emulsification efficiency by up to 25%, compared to traditional methods. Furthermore, industries involved in the manufacturing of inks and coatings are leveraging ultrasonic dispersion to achieve finer particle distribution, which enhances color vibrancy and consistency. With its versatility, ultrasonic dispersion is becoming a crucial component in achieving superior product quality across various applications.

When evaluating ultrasonic mixers, user reviews and performance metrics play a pivotal role in determining the best options available. Many users emphasize the importance of mixing efficiency, highlighting the ability of these devices to create finer dispersions and better emulsions. Positive feedback often centers around the improved uniformity of blends and the speed at which materials are processed, leading to significant time savings in production processes.

Additionally, performance metrics such as energy efficiency, durability, and maintenance needs are crucial for businesses investing in ultrasonic dispersion equipment. Users frequently report on how these factors affect overall operational costs and productivity. The integration of smart technology features also garners attention, as enhanced monitoring capabilities can provide valuable insights into mixing performance, helping users fine-tune their processes for optimal results. This focus on user experiences and practical performance data underscores the significance of selecting the right ultrasonic mixer to enhance mixing efficiency in various applications.