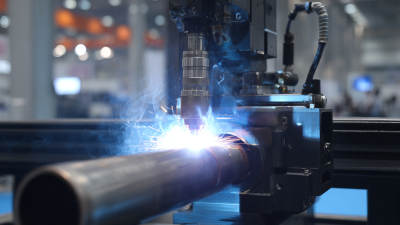

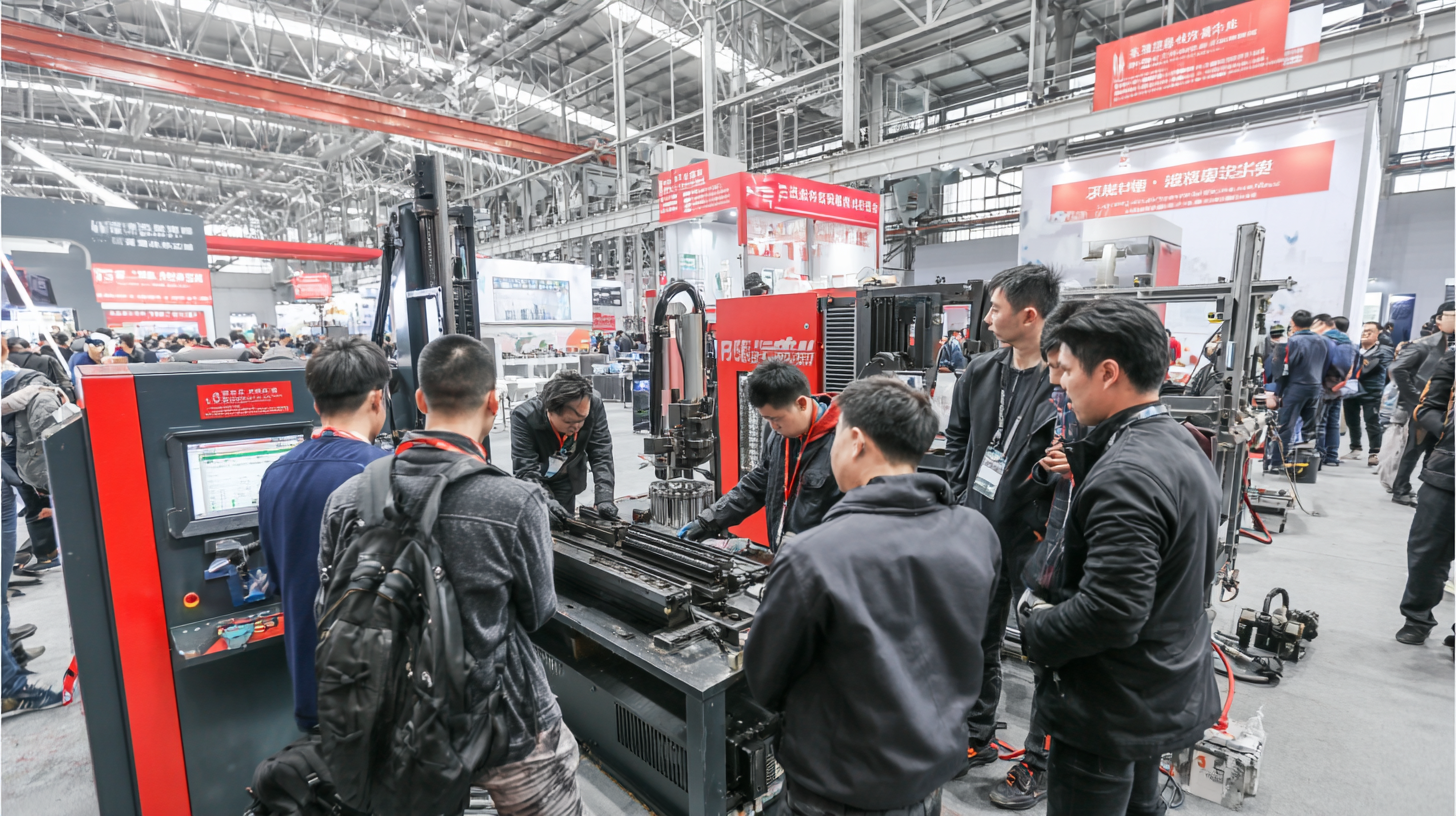

The global welding cutting machine industry is poised for significant transformation as highlighted in the upcoming 2025 China Import and Export Fair, specifically during the 138th Canton Fair. According to recent market research reports, the welding cutting machine market is projected to witness a compound annual growth rate (CAGR) of around 5.4% from 2023 to 2028, driven by the increasing demand for automation and precision in manufacturing processes. As industries strive for enhanced productivity and efficiency, the integration of advanced technologies such as robotics, IoT, and AI into welding cutting machines is becoming crucial. The fair will serve as a pivotal platform for stakeholders to exchange insights and explore innovative solutions that cater to the evolving market needs. In this context, it is essential to understand the implications of these advancements on product development and market dynamics, making the 2025 event a focal point for shaping the future of the welding cutting machine industry.

As the welding cutting machine industry prepares for the 2025 China Import and Export Fair, emerging trends are shaping the future of this vital sector. Industry reports indicate a significant shift towards automation and smart manufacturing, driven by the integration of advanced technologies such as AI and IoT. According to recent analyses, the global market for welding equipment is expected to exceed $6 billion by 2025, reflecting a compound annual growth rate of 5.2%. This growth is attributed to increasing demand across various industries, including automotive, construction, and aerospace, where precision and efficiency are paramount.

At the upcoming fair, attendees can expect to see a range of innovations, particularly in power semiconductor technology, which plays a crucial role in enhancing the performance of welding cutting machines. The adoption of high-efficiency power systems not only reduces energy consumption but also improves the overall welding quality. As noted in the latest industry insights, the implementation of such technologies could potentially decrease operational costs by up to 15%. With a focus on sustainability and operational excellence, the welding cutting machine industry is poised for a transformative period, making this year’s fair a critical opportunity for stakeholders to explore the latest developments and network with industry leaders.

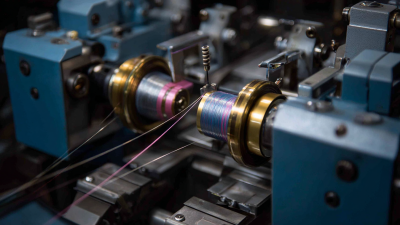

The global market for fiber laser technology is projected to experience significant growth, with its size expected to expand from $4.63 billion in 2025 to $10.75 billion by 2032. This translates to a compound annual growth rate (CAGR) of 12.8% during the forecast period, reflecting the increasing demand for advanced welding and cutting solutions. As industries seek improved precision and efficiency, fiber lasers are becoming integral in manufacturing processes, driving innovations and technological advancements within the sector.

At the 2025 China Import and Export Fair, key insights into the welding equipment market will be unveiled, stemming from the latest trends and projections. The fair will serve as a platform for leading brands and manufacturers to showcase cutting-edge technologies while providing valuable networking opportunities. Amidst a rapidly evolving industrial landscape, the event will highlight how companies are adapting to market fluctuations and enhancing their production capabilities to meet the growing global demand for high-quality welding solutions.

The 2025 China Import and Export Fair is set to unveil groundbreaking innovations in the welding cutting machinery sector, presenting a unique opportunity for industry stakeholders to explore the latest advancements. Recent market analyses indicate that the global welding equipment market is anticipated to exceed $24 billion by 2026, reflecting a CAGR of 5.5%. This growth can be attributed to the rising demand for lightweight and high-strength materials in the automotive and aerospace industries, which necessitate advanced welding technologies.

Among the innovations showcased, robotic welding systems stand out due to their efficiency and precision. These systems not only enhance productivity but also significantly reduce waste. According to a report from the International Welding Institute, the adoption of automated welding processes can decrease production costs by up to 30%.

Tips: When considering upgrades to your welding cutting machinery, focus on systems that integrate smart technology. Features like real-time monitoring and data analytics can optimize your operations and increase accuracy. Additionally, investing in training for your workforce on these advanced technologies is crucial; skilled operators can maximize the benefits of modern machinery, leading to greater overall productivity.

The welding cutting machine industry is at a pivotal crossroads, particularly as sustainable manufacturing practices gain traction globally. According to a recent report by MarketsandMarkets, the global market for eco-friendly welding machines is projected to reach USD 5.7 billion by 2026, growing at a CAGR of 7.5%. This indicates a significant shift towards technologies that not only enhance efficiency but also minimize environmental impact. Eco-friendly welding technologies, such as those utilizing low-emission gases and energy-efficient designs, are becoming the standard as manufacturers seek to comply with stringent environmental regulations and reduce their carbon footprint.

Moreover, the integration of smart technologies and IoT in welding machines further supports sustainability initiatives. A study by Grand View Research highlights that the smart welding segment is anticipated to grow at an impressive rate due to its ability to optimize energy use and reduce waste during the manufacturing process. By adopting these advanced technologies, companies can not only improve productivity but also contribute to a greener future for the industry. With the 2025 China Import and Export Fair serving as a significant platform for industry stakeholders, discussions surrounding eco-friendly welding solutions are expected to take center stage, signaling a definitive move towards sustainable practices in welding and cutting operations.

| Feature | Traditional Machines | Eco-Friendly Machines | Sustainability Benefits |

|---|---|---|---|

| Energy Efficiency | 60% efficiency | 85% efficiency | Reduced energy consumption |

| Emissions | High emissions | Low emissions | Improved air quality |

| Material Usage | Standard materials | Recyclable materials | Less waste generation |

| Noise Level | High noise | Low noise | Better workplace environment |

| Cost of Operation | Higher operational costs | Lower operational costs | Increased profitability |

The welding cutting machine industry is undergoing significant transformations, with competitive dynamics shifting notably as we approach 2025. The global welding market was valued at approximately USD 26.36 billion in 2024 and is projected to expand at a compound annual growth rate (CAGR) of 4.13% through 2033. This robust growth is being driven by increasing demand across various sectors, including construction and manufacturing, thereby intensifying the competitive landscape.

Key players in the welding cutting market are focusing on innovation and technology enhancements to maintain their competitive edge. For instance, the Asia Pacific region is experiencing a rapid expansion in the welding consumables market, with forecasts indicating notable growth driven by the demand for electrodes, flux, and shielding gases. This aligns with the broader trend observed in the industrial gases market, which is anticipated to reach USD 195.36 billion by 2032, growing at a CAGR of 7.44%. The evolution of these markets highlights the importance of strategic positioning and investment in technological advancements by major players to capitalize on emerging opportunities.