In recent years, ultrasonic dispersion equipment has gained significant attention in various industries. It is instrumental in enhancing the uniformity of mixtures, particularly in chemicals and materials. This technology uses high-frequency sound waves to break down particles. As we approach 2026, the importance of selecting the right equipment becomes crucial.

With advancements in technology, ultrasonic dispersion equipment is evolving. Companies face challenges in choosing models that meet their needs. Some equipment may promise high efficiency, yet underperform in real-world applications. Potential users should carefully consider their specific requirements.

There are various options available in the market. Each type varies in power, application, and size. Some may offer features that appear impressive but may require further evaluation. Users often report mixed experiences. Understanding the benefits and limits of this technology is essential for making informed decisions.

Ultrasonic dispersion technology has gained traction in various industries. This method employs high-frequency sound waves to break down particles. It creates a more uniform distribution in liquids. The process is efficient but not without challenges. The energy output must be carefully controlled to avoid damaging sensitive materials.

Typically, an ultrasonic disperser generates cavitation bubbles in a liquid. When these bubbles collapse, they produce shock waves. These shock waves help to mix and break apart particles. However, achieving the right balance is crucial. Too much energy can lead to overheating and alteration of the material properties.

Many industries benefit from this technology, particularly in the creation of paints and coatings. Even within these applications, results can vary. Proper calibration is essential for optimal outcomes. Mistakes in settings can lead to inconsistencies. Thorough testing and adjustments are vital to mastering the process.

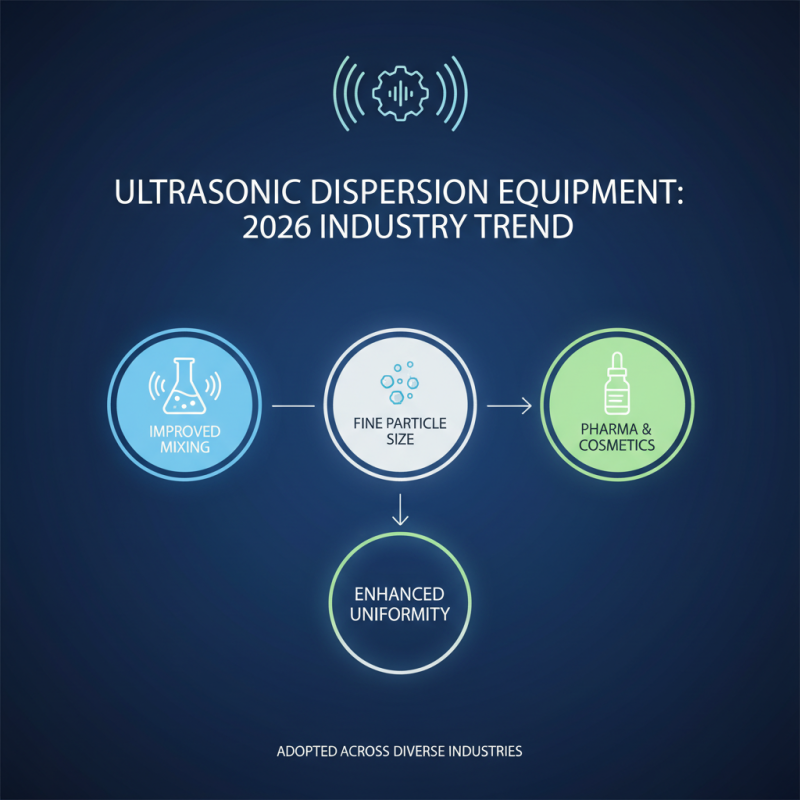

Ultrasonic dispersion equipment is gaining traction for various industries in 2026. It offers unique features that improve mixing and dispersing processes. One of the key aspects is its ability to create fine particle sizes. This is essential for industries like pharmaceuticals and cosmetics. The equipment uses ultrasonic waves to achieve uniformity.

Another significant feature is its energy efficiency. Many devices are designed to consume less power while providing high performance. This can lead to cost savings over time. However, not all models provide the same level of efficiency. Users need to assess this before making a decision.

Customization options are also prevalent. Users can often adjust frequency and amplitude settings based on specific needs. This offers flexibility but may overwhelm some users. It’s crucial to have a clear understanding of requirements. Moreover, the market is filled with options, making it challenging to choose the right fit. Each piece of equipment has its pros and cons that warrant careful consideration.

Ultrasonic dispersion is becoming essential across many industries. This technology has proven to enhance the mixing and dispersing of materials. From food production to pharmaceuticals, the benefits are significant. Ultrasonic waves create high shear forces. These forces break down particles for a uniform mixture. Companies report increased efficiency and consistency in their products.

Using ultrasonic dispersion can improve quality control. For food processors, achieving a smooth texture is crucial. This method can also reduce processing times. However, equipment costs can be high. Some may question if the investment pays off in the long run. It's vital to consider production scale and specific needs.

Tip: Before deciding, analyze your current mixing process. Do small-scale tests to gauge potential benefits. Another suggestion is to consult industry peers. They can share valuable insights on their experiences. In the end, understanding your unique requirements is key.

Ultrasonic dispersion equipment is gaining attention in various industries, from food to pharmaceuticals. The growing demand for uniform particle sizes drives interest in these machines. According to a recent industry report, the ultrasonic dispersion market is projected to grow at a CAGR of 9.5% by 2026. This growth raises critical questions about the return on investment.

The initial cost of ultrasonic equipment can be substantial. Businesses must weigh this investment against the efficiency gains. Reports suggest that companies can reduce processing times by up to 30% when utilizing ultrasonic technology. However, the energy consumption of these devices can also be significant, impacting operational costs. For some, this might not justify the upfront expenses.

Moreover, maintenance is a factor to consider. Regular upkeep can incur additional costs, which might affect the overall savings. The technology does not always suit every application, leading to potential waste in investment. For some small manufacturers, the benefits might not lead to expected efficiency. Understanding the specific needs of the business is essential before making a decision.

| Model | Frequency (kHz) | Output Power (W) | Price (USD) | Efficiency (%) | Warranty (Years) |

|---|---|---|---|---|---|

| Model A | 20 | 1000 | 5000 | 85 | 2 |

| Model B | 28 | 800 | 4500 | 90 | 3 |

| Model C | 40 | 1200 | 6500 | 88 | 5 |

| Model D | 20 | 1500 | 6000 | 92 | 4 |

| Model E | 30 | 900 | 4800 | 87 | 2 |

The landscape of ultrasonic dispersion technology is evolving rapidly. In 2026, advancements promise to enhance efficiency and precision. Emerging techniques focus on minimizing energy consumption while maximizing dispersion quality. This will change how industries develop emulsions and mixtures. Companies must adapt to these innovations to stay competitive.

Sustainability is becoming a key driver. Many ultrasonic dispersion devices are designed with eco-friendly principles in mind. Reducing chemical waste is crucial. However, the transition to greener technologies is not without challenges. Some users may find these new systems complicated. Training staff to operate advanced equipment can pose difficulties.

Moreover, as technology advances, the cost of adoption remains a concern. Smaller enterprises may struggle with investment requirements. Balancing the benefits of superior dispersion against upfront costs will require thoughtful evaluation. Continuous innovation is essential, but businesses must also reflect on their specific needs and capabilities. Finding the right fit can be challenging but rewarding in the long term.