As the demand for high-quality tinning solutions continues to rise, the market for Tinning Machines is expected to witness significant growth in the coming years, particularly by 2025. Industry reports indicate that the global market for tinning equipment is projected to expand at a CAGR of 7.5%, driven by advancements in technology and increasing applications across various sectors, including electronics and automotive manufacturing. According to Dr. Emily Hart, a leading expert in manufacturing technology, "The evolution of Tinning Machines is reshaping how industries improve their production efficiencies and product quality."

In this ever-evolving landscape, it's crucial for businesses to understand the key features and innovations to consider when purchasing a Tinning Machine. Factors such as automation capabilities, precision in application, and the ability to handle diverse substrate materials are becoming increasingly important for manufacturers aiming to stay competitive. As we delve into the top tinning machines for 2025, this guide will provide insights into essential criteria to evaluate, ensuring that you make an informed decision for your operational needs. With the proper knowledge and resources, companies can leverage the advancements in Tinning Machine technology to enhance their productivity and output quality significantly.

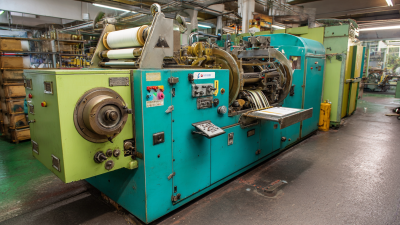

Tinning machines are specialized devices designed to apply a thin layer of tin onto metal surfaces, primarily for the purpose of protection and enhancement. The tinning process not only prevents corrosion but also improves solderability, making these machines essential in various manufacturing applications. Industries such as electronics, automotive, and plumbing benefit greatly from the use of tinning machines, as they ensure that components maintain their integrity and functionality over time.

Understanding the applications of tinning machines reveals their importance in production lines. In the electronics industry, tinning is crucial for enhancing the lifespan and reliability of circuit boards by providing a conductive surface that facilitates solder attachment. Similarly, in the automotive sector, tinning can protect metal parts exposed to the elements, thereby reducing maintenance costs and prolonging the effectiveness of components. Additionally, in plumbing, tinning helps with the joining of pipes, ensuring watertight seals that are essential for system integrity. These diverse applications underscore the versatility and necessity of tinning machines across multiple sectors, making them critical tools in modern manufacturing.

When considering the purchase of a tinning machine, it's essential to focus on key features that can enhance productivity and efficiency. One of the foremost aspects to evaluate is the machine's ease of operation. User-friendly controls and a clear interface can significantly reduce training time for new operators. Additionally, consider the machine's speed and capacity; it's important to select a model that aligns with your production requirements to avoid bottlenecks in your workflow.

Another critical feature is the durability and maintenance of the machine. Look for robust construction materials that can withstand rigorous use, as well as models designed for easy maintenance. A machine that requires frequent repairs can become a significant setback in production. Additionally, assess the machine’s energy consumption; opting for an energy-efficient model can lead to cost savings over time.

Tips for selecting the right tinning machine include conducting thorough research and comparing different models based on user reviews and expert recommendations. Make sure to ask vendors about after-sales support and warranties, as these can be indicators of reliability. It's also advisable to invest in features that provide versatility, allowing you to adapt the machine for various tinning processes in the future, ensuring long-term utility.

| Model | Automatic/Manual | Production Speed (cans/min) | Material Compatibility | Compact Size (Yes/No) | Price Range ($) |

|---|---|---|---|---|---|

| Model A | Automatic | 100 | Steel, Aluminum | Yes | 5000 - 7000 |

| Model B | Manual | 40 | Aluminum | No | 2000 - 3000 |

| Model C | Automatic | 120 | Steel | Yes | 6000 - 8000 |

| Model D | Semi-Automatic | 80 | Aluminum, Tin | Yes | 4000 - 5000 |

| Model E | Automatic | 110 | Tin | No | 7000 - 9000 |

When searching for the top tinning machine models to watch in 2025, it is important to consider various factors that contribute to their performance and efficiency. One notable trend is the integration of advanced technology, such as automation and smart controls, which enhance precision and reduce labor costs. Models equipped with user-friendly interfaces allow operators to adjust settings easily, ensuring consistent results across different production batches. Additionally, machines that support quick-change tooling and versatile configurations can cater to a range of tinning requirements, making them a valuable asset for any manufacturing setup.

Another crucial aspect to evaluate is the machine's durability and maintenance needs. In 2025, the focus is on machines that boast robust construction and materials that can withstand the rigors of heavy use. Low maintenance models with easy access to components for servicing can save time and costs in the long run. Sustainability features, such as energy efficiency and waste reduction mechanisms, will also be prominent in the upcoming models, appealing to environmentally conscious manufacturers looking to minimize their ecological footprint while optimizing productivity.

When considering the purchase of a tinning machine in 2025, potential buyers must closely evaluate pricing trends and budgeting strategies. According to a recent analysis from the Machinery Market Research Institute, the average price of industrial tinning machines is projected to rise by approximately 15% over the next year due to increases in raw material costs and supply chain disruptions. This data suggests that businesses looking to invest in this technology should prepare for higher expenditures and could consider purchasing sooner rather than later to take advantage of current pricing.

Budgeting for tinning machines also involves factoring in not just the upfront cost, but also ongoing operational expenses. Industry reports indicate that maintenance and operational costs account for nearly 20-30% of the total ownership costs over a machine's lifespan. Additionally, energy efficiency is becoming increasingly important; machines with upgraded features can lead to savings of up to 25% in energy costs, which is a significant factor for businesses aiming to keep their operational budget in check.

Understanding these financial aspects will help companies make informed decisions that align with their financial capabilities and operational needs when selecting the best tinning machine for the upcoming year.

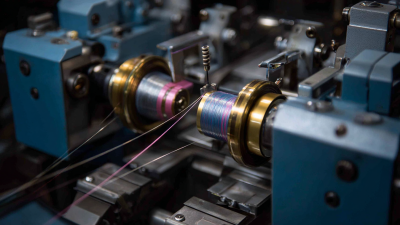

Proper maintenance of tinning machines is crucial for ensuring their optimal performance and longevity. One of the fundamental aspects of maintenance is regular cleaning. Residues of flux and solder can accumulate over time, leading to clogs and operational inefficiencies. To clean the machine, use appropriate solvents and tools recommended in the user manual to avoid damage. Scheduled cleaning intervals based on machine usage should be established to maintain consistent performance.

Another important maintenance tip involves inspecting the machine's heating elements and temperature controls. Tinning processes require precise temperature settings for effective solder adhesion. Regular calibration of the temperature sensors and replacing any faulty heating elements can prevent overheating or inadequate soldering. Additionally, keeping an eye on electrical connections and wiring ensures safety and reliability during operation. Implementing a routine check for wear and tear will help identify parts that may need replacement before they cause significant problems.

Lubrication plays a vital role in maintaining moving parts within the tinning machine. Using the correct type of lubricant, apply it to bearings and other friction points as recommended by the manufacturer. Proper lubrication reduces wear, promotes smoother operation, and minimizes downtime for repairs. Additionally, documenting maintenance activities will aid in tracking performance and anticipating future needs, ultimately contributing to a more efficient tinning process.