As the demand for high-quality optics increases, the Lens Coating Machine market is evolving rapidly. According to a recent industry report, the global lens coating market is projected to reach USD 9.5 billion by 2026, growing at a CAGR of 6.2%. This growth reflects the rising need for advanced coating technologies in various applications, including medical devices, automotive, and consumer electronics.

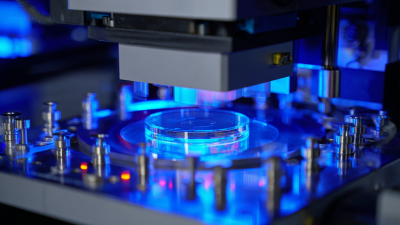

Selecting the right Lens Coating Machine involves several key factors. Efficiency and precision in the coating process are paramount. Machines must deliver consistent results to meet stringent quality standards. Additionally, users must consider the versatility of these machines, ensuring they can handle various materials and coatings. Notably, while many machines offer impressive specifications, not all live up to their promises, necessitating thorough research before investing.

With continuous innovations, manufacturers also face the challenge of keeping up with technological advancements. This can lead to confusion, as newer models may introduce features that are not yet fully understood. Understanding these complexities is essential, ensuring that the chosen Lens Coating Machine aligns with production needs and budget constraints.

The landscape of lens coating machines in 2026 is evolving rapidly. Advancements focus on precision and efficiency. Modern machines will likely feature enhanced automation processes. This change promises to reduce human error and increase production rates. Moreover, the integration of smart technology will allow for better monitoring and control. Users will appreciate the ability to track performance in real-time.

However, with these advancements come challenges. Operators must adapt to new interfaces and software. Training programs may struggle to keep pace with rapid technological advancements. As machines become more sophisticated, user error could increase without proper guidance. Additionally, maintenance requirements may become more complex. Users may find it frustrating when unexpected issues arise, leading to downtime.

Looking ahead, a greater emphasis on sustainability is expected. Machine designs might prioritize energy efficiency and waste reduction. This could reflect a broader industry trend toward environmentally friendly practices. Users will need to stay informed about these changes to take full advantage of what new machines offer. Balancing innovation with reliability will be a key consideration for businesses.

When looking for lens coating machines in 2026, focus on key features. Precision is vital. The machine must deliver consistent results. Look for advanced technology that ensures even coating. Uneven surfaces can lead to poor performance. It’s essential to analyze user feedback on current models. You might discover common issues or advantages others have faced.

Tips: Consider the machine's energy efficiency. Energy costs can add up quickly. An eco-friendly model saves money in the long run. Also, investigate maintenance requirements. Machines requiring too much service can disrupt production.

Customizability is another feature to assess. A versatile machine adapts to various lens sizes and types. It might present a learning curve at first. However, over time, your team will gain expertise. Lastly, remember to evaluate the software integration. A user-friendly interface helps streamline operations. Complicated systems can frustrate operators and slow down processes.

When exploring the top lens coating machines for 2026, several key features stand out. First, the precision of the coating process is crucial. Machines should ensure even application across various lens types. Consistency in coating thickness impacts product quality. Look for machines with advanced monitoring systems. These systems can enhance accuracy and reduce waste.

Tip: Always check the machine's calibration capabilities. Regular calibration keeps the coating process reliable.

Another factor is ease of use. Complex machines can lead to mistakes. User-friendly interfaces help operators manage them efficiently. Ideally, training should be straightforward and quick. Maintenance should also be easy to perform. Parts should be accessible for routine cleaning and repairs.

Tip: Read user reviews about the machine’s reliability. Real-world experiences reveal hidden pros and cons.

Lastly, consider the machine's adaptability. Will it cater to future advancements? A machine that can handle upcoming technologies may save costs long-term. This flexibility can benefit manufacturers seeking to expand their range of products. Go for machines that stay relevant with industry trends.

Tip: Think about your future needs. Avoid machines that may become obsolete quickly.

| Feature | Machine A | Machine B | Machine C |

|---|---|---|---|

| Coating Technology | ALD | SPM | CVD |

| Production Speed (units/hour) | 50 | 40 | 60 |

| Max Lens Size (diameter in mm) | 80 | 90 | 70 |

| Energy Consumption (kWh) | 3.5 | 4.2 | 3.0 |

| User Interface | Touchscreen | Button Control | Touchscreen |

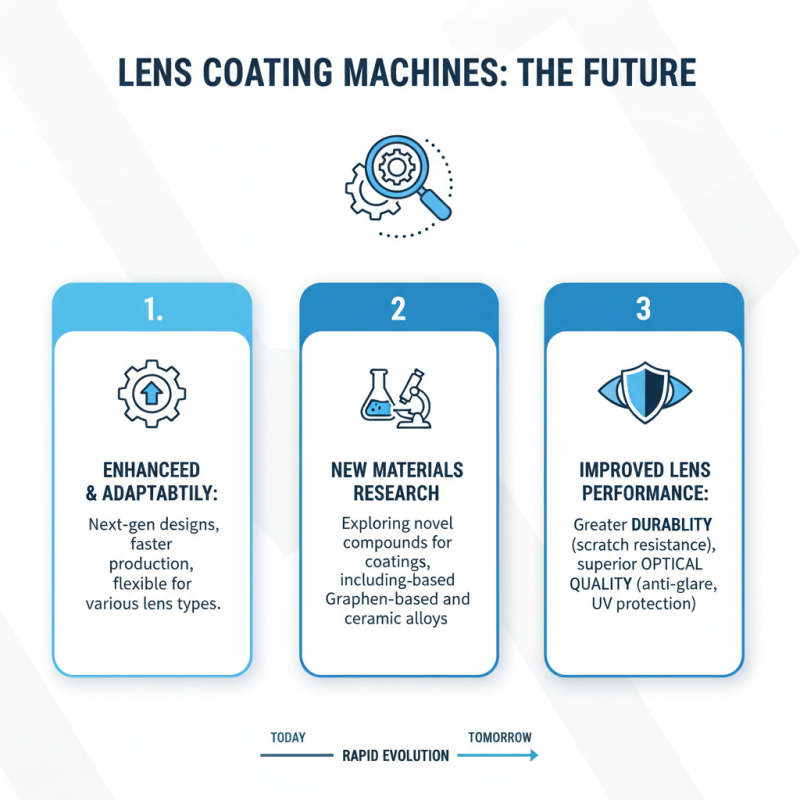

The lens coating machine industry is rapidly evolving. Future designs will focus on enhanced efficiency and adaptability. Manufacturers are researching new materials for coatings. This may lead to improved durability and performance of lenses.

One key trend is automation. Automatic lens coating machines can reduce human error. However, this reliance on technology raises questions about maintenance and quality control. Are these machines foolproof? Regular checks are necessary to ensure optimal function.

Sustainability is another important consideration. Eco-friendly materials must be a priority. Many companies are looking for ways to minimize waste. Innovative coatings might help reduce energy usage during the coating process. The future is bright, yet challenges remain. How can companies balance efficiency and sustainability? This will be crucial in shaping the future of lens coating.

When considering lens coating equipment in 2026, maintenance is crucial. Regular checks can prevent small issues from escalating into major problems. Routine cleaning of the components is essential. Dust and debris can compromise quality. A thorough inspection schedule helps identify wear over time.

Support services should not be overlooked. 24/7 customer support can make a significant difference. Quick access to technical assistance means less downtime. A well-trained support team can troubleshoot effectively. Maintenance contracts can also provide peace of mind. They offer scheduled service at a predictable cost.

Nevertheless, users should reflect on their specific needs. Not all machines will suit every operation. Assessing production volume and type of lenses is necessary. Customization options can improve efficiency. Keeping an adaptable approach can lead to better outcomes. As technology advances, staying informed will be beneficial.