Industrial Spray Nozzles play a crucial role in various manufacturing processes, enhancing efficiency and performance across a wide range of applications. From automotive painting to food processing, these nozzles are designed to deliver precise and uniform spray patterns, optimizing material usage and improving overall quality. The choice of the right nozzle can significantly influence the effectiveness of a spray system, leading to better outcomes in terms of product finish, resource conservation, and operational cost savings.

In the pursuit of operational excellence, industries seek to employ the best tools and technologies available. Understanding the types and functionalities of Industrial Spray Nozzles is essential for engineers and production managers looking to maximize their processes. This guide presents a curated list of the top 10 industrial spray nozzles that stand out in terms of performance, durability, and efficiency. By exploring these options, businesses can make informed decisions that align with their specific needs, ultimately driving productivity and enhancing product quality.

Industrial spray nozzles play a vital role in various manufacturing processes, providing efficient liquid application for cooling, coating, cleaning, and other functions. Understanding the types and functions of these nozzles is crucial for optimizing performance and ensuring efficient operations. The primary types of industrial spray nozzles include air atomizing nozzles, hydraulic nozzles, and flat fan nozzles, each designed to meet specific application requirements. For instance, air atomizing nozzles are known for their ability to create fine mist droplets and are commonly used in processes that require a delicate application, such as in food processing or chemical manufacturing.

According to a recent report by MarketsandMarkets, the global market for spray nozzles is projected to reach USD 5.9 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.8% from 2020. This growth is driven by the increasing demand for efficient fluid management systems across industries such as automotive, pharmaceuticals, and agriculture. Additionally, understanding the flow characteristics and spray patterns generated by different nozzle types can significantly impact resource utilization. For instance, nozzles designed with specific angles and capacities can enhance coverage while reducing waste, leading to lower operational costs and improved sustainability within production processes.

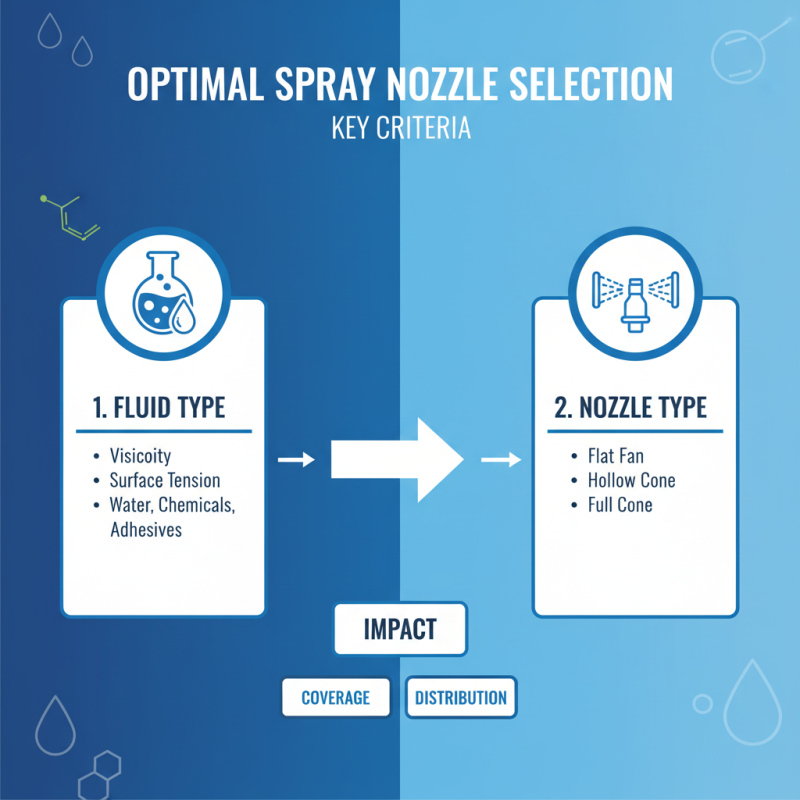

When selecting optimal spray nozzles for various applications, several key criteria must be taken into account to ensure both performance and efficiency. First and foremost, the type of fluid being sprayed plays a crucial role. Different fluids, whether they are water, chemicals, or adhesives, have varying viscosities and surface tensions, which impact the nozzle design and spray pattern required for effective application. Understanding the characteristics of the fluid will guide the selection of spray nozzle type – whether it’s a flat fan, hollow cone, or full cone nozzle – to achieve the desired coverage and distribution.

Another important criterion is the operating pressure and flow rate. Nozzle performance is highly dependent on these parameters, as they directly influence spray droplet size and velocity. It is vital to select a nozzle that operates efficiently within the designated pressure range to avoid issues such as overspray or incomplete coverage. Additionally, factors such as the environment in which the nozzle will be used and the specific application requirements—like the need for precision in coating or the removal of contaminants—should also be considered, as they will affect both nozzle selection and the overall system design. By evaluating these factors, users can make informed decisions that maximize the effectiveness of their spray operations.

When selecting industrial spray nozzles, understanding their features and benefits is essential for optimizing performance and efficiency. Different nozzle types, such as flat fan, hollow cone, and solid stream, serve various purposes in industrial applications. Flat fan nozzles offer wide spray patterns which are beneficial for surface coating, while hollow cone nozzles are ideal for applications requiring fine mist distribution, such as cooling or dust suppression. Solid stream nozzles excel in tasks that need concentrated pressure, such as cleaning heavy machinery.

Tips for choosing the right nozzle include considering the output flow rate and pattern. Assess the specific application requirements — for instance, environmental conditions, the material being sprayed, and the desired coverage area. Additionally, look for nozzles made from durable materials to withstand high-pressure environments and corrosive substances.

Another important aspect is maintenance and serviceability. Regularly check and clean your nozzles to prevent clogging, which can lead to decreased efficiency. Investing in nozzles with easy-to-clean designs can save time and prolong the lifespan of the equipment. Being proactive in maintenance not only enhances performance but also improves overall productivity in industrial operations.

| Nozzle Type | Applications | Flow Rate (GPM) | Pressure Rating (PSI) | Material | Coverage Pattern | Key Benefits |

|---|---|---|---|---|---|---|

| Flat Fan Nozzle | Surface cleaning, coating applications | 0.5 - 10 | 40 - 150 | Brass, Stainless Steel | Flat | Uniform coverage, adjustable spray angle |

| Hollow Cone Nozzle | Cooling, dust control | 1 - 15 | 30 - 100 | Plastic, Stainless Steel | Hollow Cone | High droplet density, excellent coverage |

| Full Cone Nozzle | Washing, cooling | 0.5 - 20 | 50 - 200 | Aluminum, Stainless Steel | Full Cone | Consistent flow, good for wide coverage |

| Air Atomizing Nozzle | Spray drying, humidification | 0.1 - 5 | 20 - 80 | Brass, Stainless Steel | Fine mist | High atomization efficiency |

| Spray Rod Nozzle | Large area coverage | 1 - 25 | 15 - 100 | PVC, Stainless Steel | Variable | Effective for wide areas, adjustable length |

| No-Ring Nozzle | Washing, surface treatment | 0.5 - 10 | 60 - 130 | Stainless Steel | No-Ring | Minimal clogging, extended lifespan |

| Drift Control Nozzle | Pesticide application, dust suppression | 0.5 - 12 | 30 - 120 | Plastic, Ceramic | Controlled Drift | Reduces waste, precise application |

| Stream Nozzle | Targeted cleaning | 0.1 - 5 | 100 - 300 | Stainless Steel | Solid Stream | High impact, precise delivery |

| Misting Nozzle | Cooling, humidifying | 0.5 - 8 | 30 - 60 | Bronze, Stainless Steel | Fine Mist | Efficient cooling, energy saving |

Maintaining the efficiency of industrial spray nozzles is crucial for optimal performance and cost-effectiveness. Regular maintenance not only extends the lifespan of spray nozzles but also ensures consistent spray patterns and reduced waste. One of the key practices is to inspect and clean nozzles frequently. Debris accumulation can lead to clogging, which affects the nozzle’s ability to spray effectively. Cleaning can be accomplished using soft brushes or specialized cleaning solutions that do not damage the nozzle material.

Tips for maintaining spray nozzle efficiency include regularly checking for leaks, as small leaks can lead to significant losses in efficiency. Additionally, it’s important to monitor the spray output and pattern to ensure they align with operational standards. Adjustments may be necessary if discrepancies are noticed, as this can indicate issues such as wear and tear or improper installation.

Another essential aspect of maintaining spray nozzle efficiency is correct selection and usage. Using the right nozzle type for the specific application is key. Make sure to understand the fluid dynamics applicable in your operations and adjust the pressure and flow rates accordingly. Training operators on best practices can also help in avoiding misuse, prolonging the life of the nozzles, and ensuring that they perform at their best under various conditions.

Advancements in spray nozzle technology have transformed the industrial sector, leading to enhanced performance and efficiency across various applications. Modern spray nozzles are designed with precision in mind, utilizing advanced materials and engineering techniques to optimize fluid dynamics. These innovations result in better atomization, improved spray coverage, and reduced overspray, which not only enhances process quality but also minimizes waste and operational costs. As industries strive for sustainability and efficiency, investing in high-performance spray nozzles becomes a critical factor in achieving these goals.

Tip: Regular maintenance of spray nozzles can extend their lifespan and maintain optimal performance. Ensure that nozzles are cleaned periodically and free from blockages that could disrupt the spray pattern.

Moreover, the integration of smart technology into spray nozzle systems allows for real-time monitoring and control. This advancement provides users with valuable data regarding flow rates, pressure, and nozzle wear, enabling timely adjustments that enhance productivity. By harnessing such technologies, manufacturers can respond swiftly to changing operational needs, ensuring that efficiency remains at the forefront of their processes.

Tip: When selecting a spray nozzle, consider the specific requirements of your application, such as droplet size and spray angle, to achieve the best results for your operations.