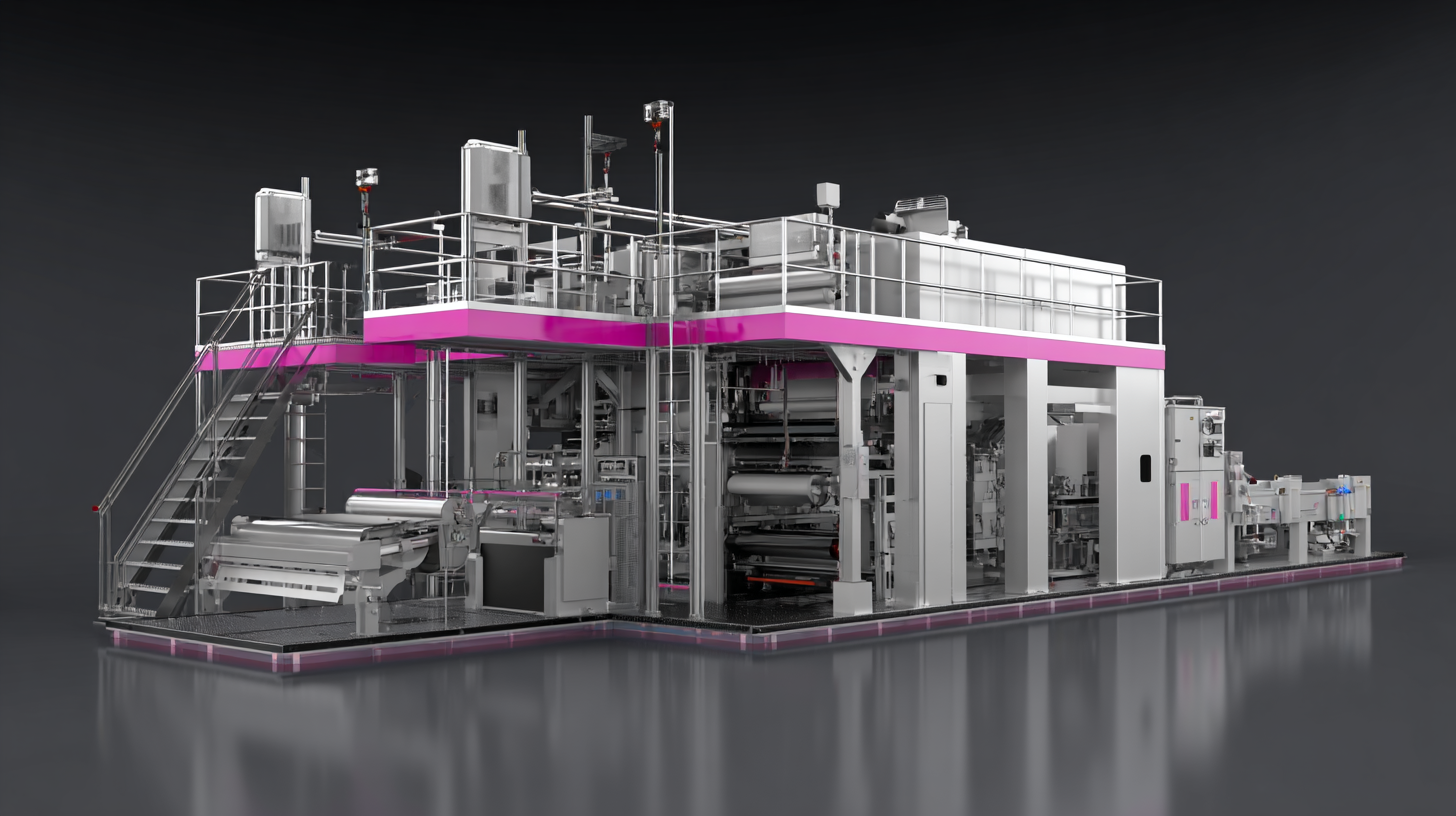

In the rapidly evolving landscape of manufacturing, the efficiency of production processes can significantly influence a company's competitive edge. One critical component of this landscape is the Industrial Coating Machine, a technology that has revolutionized how industries apply protective and aesthetic coatings to their products. According to Dr. Emily Stewart, a renowned expert in industrial automation, "The right industrial coating machine not only enhances the quality of the finish but also streamlines workflows, ultimately driving productivity gains."

As industries strive to achieve higher levels of performance, selecting the most effective coating technology becomes paramount. With numerous options available, it can be challenging for manufacturers to determine which machines will best fit their operational needs. This article will explore the top 10 industrial coating machines that are designed to boost production efficiency, delving into the unique features and benefits that each machine offers. By understanding the capabilities of these advanced systems, manufacturers can make informed decisions that will enhance their operations and keep them ahead in a competitive market.

In today's industrial landscape, selecting high-efficiency coating machines is crucial for enhancing production efficiency. The significance of these machines cannot be overstated; they play a vital role in reducing operational costs and ensuring optimal resource utilization. As industries face increasing pressure to meet sustainability targets, the integration of energy-efficient technologies becomes imperative. For example, advanced coating machines equipped with intelligent features can minimize waste and energy consumption, yielding significant long-term savings.

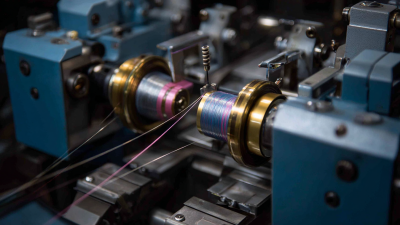

Moreover, the adoption of state-of-the-art coating technologies aligns with the broader trends in manufacturing and industrial upgrades. With the rise of laser coating services and automation, businesses are not only improving their production rates but also enhancing the quality of their finish products. By incorporating high-performance machines, industries can keep pace with the evolving market demands, particularly in sectors like aerospace, automotive, and electronics, where precision and consistency are paramount. The future of industrial production will increasingly rely on such innovations to maintain competitiveness and meet regulatory standards.

When considering industrial coating machines, several key performance metrics can significantly impact production efficiency. According to a report by MarketsandMarkets, the global market for industrial coating equipment is expected to reach $27.5 billion by 2025, indicating strong industry growth and the increasing need for high-performance machines. Essential features to evaluate include application speed, coating thickness consistency, and reduction of material waste.

Machines that can achieve a coating speed of over 300 meters per minute and uniform thickness tolerance of ±5% are vital for maintaining high throughput and quality standards.

Furthermore, the technology used in coating machines plays a crucial role in performance. For instance, machines equipped with advanced automation and real-time monitoring systems can optimize production processes. A study by Grand View Research highlights that companies implementing such technologies report a 25% increase in efficiency and a significant reduction in downtime. Moreover, energy-efficient machines can cut operational costs, with studies indicating potential savings of up to 30% in energy consumption when using the latest eco-friendly technologies. Selecting machines that are built with these features ensures longevity, reliability, and ultimately, a positive return on investment.

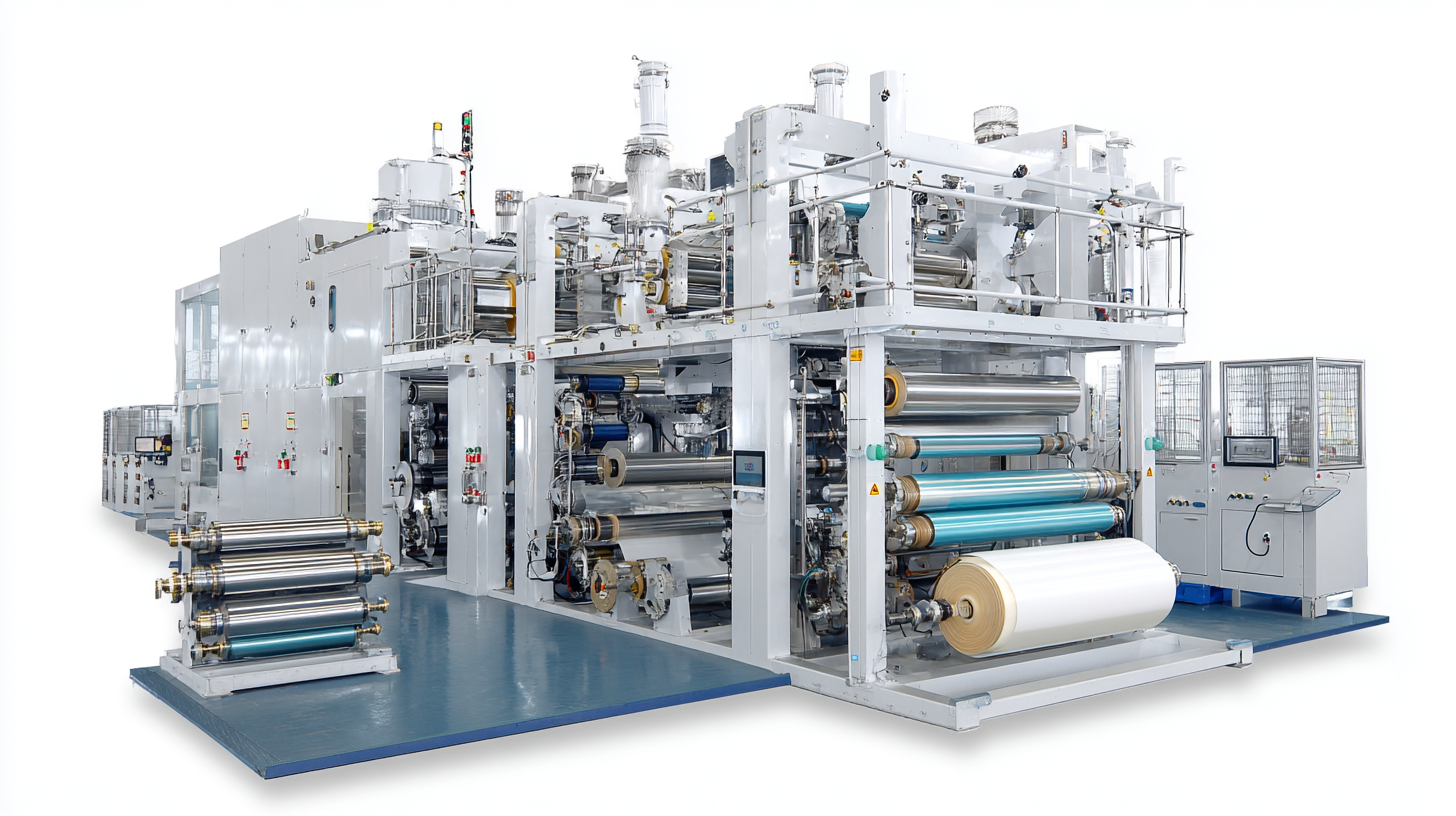

Upgrading industrial coating machines can significantly impact profit margins, bolstered by the advancements in technology and efficiency. According to a report by Mordor Intelligence, the global industrial coatings market is expected to grow at a CAGR of 5.5% from 2021 to 2026. This growth is driven by the increasing demand for high-quality coatings that enhance durability and reduce maintenance costs. By investing in modern coating equipment, manufacturers not only improve their production capabilities but also align with evolving market demands, ultimately leading to enhanced returns on investment (ROI).

Furthermore, a study by the Coating Industry Market Research Group indicates that companies that upgrade their coating lines can increase their production efficiency by up to 30%. This improvement is attributed to faster processing times and reduced waste, allowing businesses to meet tighter deadlines and lower operational costs. Enhanced automation features in newer machines also allow for real-time monitoring, which aids in minimizing defects and rework. As manufacturers weigh the decision to upgrade, these compelling statistics showcase the potential for improved profit margins, making a strong case for investment in quality coating machinery.

In the rapidly evolving landscape of industrial coating technology, several innovations have emerged to significantly enhance production efficiency. One of the most notable trends is the integration of automation and robotics into coating processes. Automated systems not only streamline operations but also improve precision and consistency, reducing material waste and operational downtime. This shift towards automation ensures that coatings are applied uniformly, resulting in superior finishes and increased throughput.

Another major trend is the development of environmentally friendly coating materials. As industries face increasing pressure to adopt sustainable practices, new formulations are being designed to minimize volatile organic compounds (VOCs) and hazardous substances. These eco-friendly coatings offer comparable performance to traditional options while enabling companies to meet regulatory requirements and improve their corporate social responsibility profile. This dual focus on efficiency and sustainability is reshaping the industrial coating landscape, driving innovations that cater to both productivity needs and environmental stewardship.

Proper maintenance of industrial coating machines is essential for maximizing their lifespan and improving production efficiency. According to a report by Research and Markets, regular maintenance can increase the operational lifespan of machinery by up to 50%. With such significant potential for increased longevity, understanding best practices is crucial for facility managers.

One key tip is to conduct regular inspections. Daily checks can identify wear and tear before they escalate into costly repairs. Make sure to check the fluid levels, and clean filters regularly to prevent clogs that can impede the machine's performance. Additionally, adhering to manufacturer guidelines for maintenance schedules is imperative. The Association of Equipment Manufacturers notes that non-compliance with maintenance schedules can lead to an increase in downtime by 20%, which directly impacts overall production efficiency.

Another important practice is to ensure that operators are well-trained in the machine's use and maintenance. Properly trained staff can perform minor repairs and troubleshoot problems effectively, reducing reliance on external assistance and enhancing productivity. For example, allowing operators to get familiar with machine diagnostics can lead to quicker resolutions of issues. Engaging with resources, such as the latest industry reports, can provide insights on optimizing maintenance routines tailored to specific equipment types.