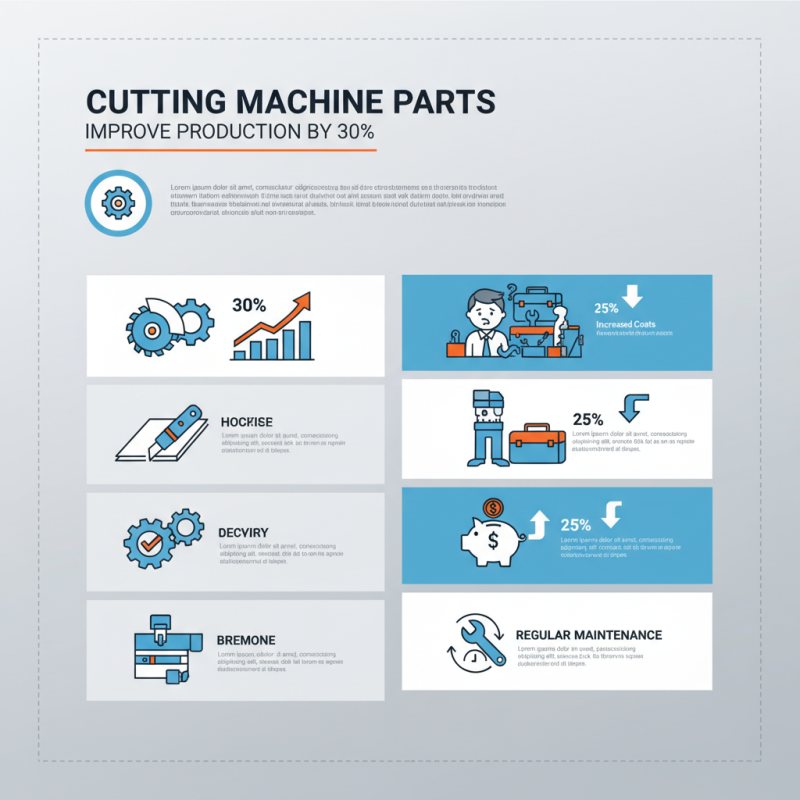

In the manufacturing industry, understanding "Cutting Machine Parts" is crucial. As reported by the Machinery Research Institute, efficient cutting equipment can improve production output by 30%. Specific parts, such as blades and motors, play a vital role in this efficiency. The right components ensure precise cuts and minimize downtime.

Yet, selecting the best cutting machine parts can be challenging. There are numerous options available, each with varying qualities and functionalities. A 2022 report from Industrial Equipment Insights indicates that 25% of companies struggle with part selection. This can lead to increased costs and longer lead times. Knowing the essential parts can aid in making informed decisions.

Investing in high-quality cutting machine parts can yield significant returns. It reduces material waste and enhances product quality. However, many businesses overlook the importance of maintenance. Regular checks and replacements are often neglected. A proactive approach can ultimately prevent unexpected breakdowns and costly repairs. Understanding these nuances is crucial for success in a competitive market.

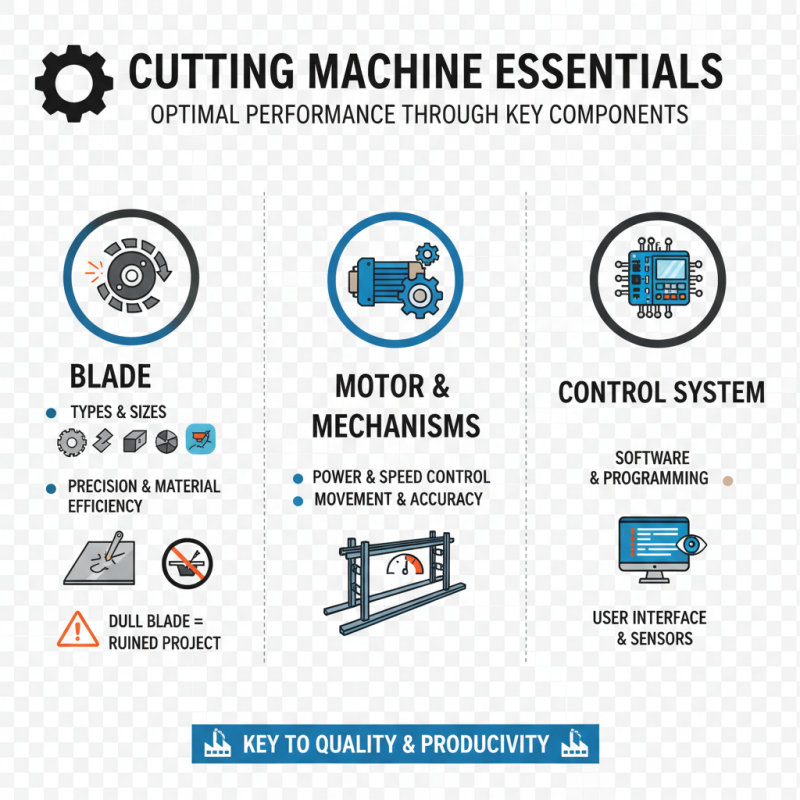

Cutting machines are crucial in various industries. Understanding their essential components is vital for optimal performance. One key part is the blade, which comes in different types and sizes. The right blade enhances precision. A dull blade can ruin a project, leading to wasted materials.

Another important component is the motor. It powers the machine and influences cutting speed. A strong motor allows for smoother operation, but it can generate excess heat. Regular maintenance is necessary to prevent overheating. Moreover, the frame of the cutting machine must be sturdy. A weak frame can lead to vibrations, affecting accuracy.

Electronic controls also play a significant role. These components automate functions and ensure consistent performance. However, errors in programming can lead to mistakes. Operators need proper training to avoid costly errors. In the end, knowledge of these components helps improve efficiency and reduce waste.

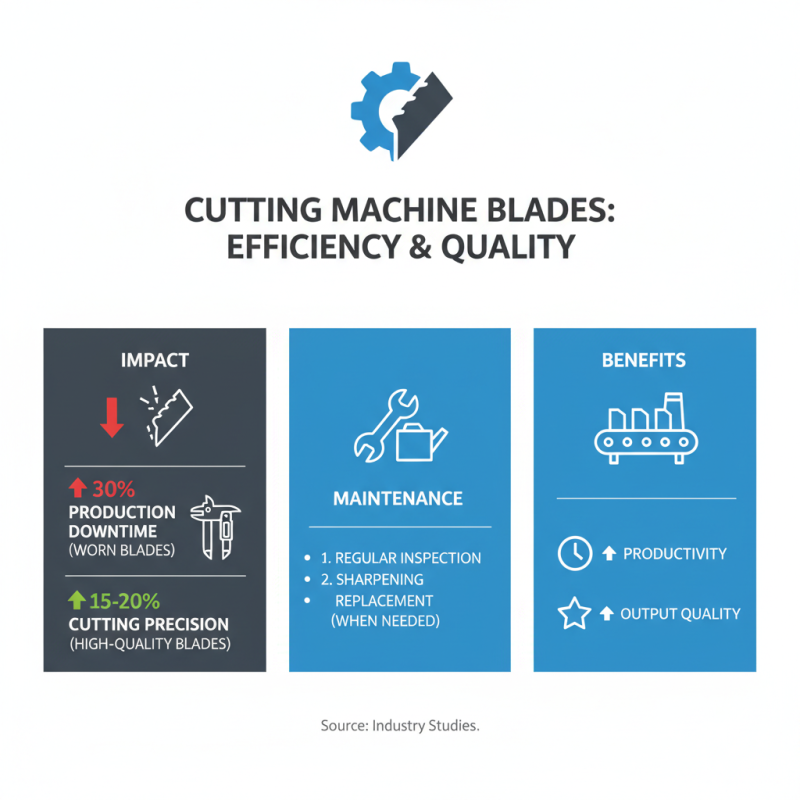

Cutting machine blades play a crucial role in various industries. These blades can affect the efficiency and quality of the cutting process. In fact, studies show that up to 30% of production downtime is caused by worn or defective blades. Proper maintenance is essential to avoid this issue. High-quality blades can increase cutting precision by 15-20%. This provides a significant boost in both productivity and output quality.

The materials used in blades are diverse. Many blades are made from high-speed steel (HSS) or carbide. These materials offer durability and resistance to wear. However, they can be expensive. Finding the right balance between cost and performance can be challenging. Statistics indicate that improper blade selection can lead to a 25% increase in operational costs.

Furthermore, blade issue resolution often requires downtime for inspection and replacement. Some operators overlook the importance of blade types. Using the wrong blade can lead to poor cutting quality. It’s crucial to consider the specific cutting requirements for each task. Ignoring these factors may result in wasted resources and lower profitability. Choosing the right blade is not just a matter of preference; it’s essential for operational success.

Cutting machines rely heavily on motors for their operations. Understanding the types of cutting machine motors is crucial. There are several motor types, each serving unique functions. For instance, stepper motors are often used for precision tasks. They move in distinct steps, allowing for accurate positioning. This precision is vital in applications like CNC machines.

Another common motor is the servo motor. Servo motors are known for their speed and control. They are often used in industrial settings where efficiency matters. These motors can adjust power based on feedback, enhancing performance. However, they can be more complex to set up and maintain.

Brushed DC motors also play a role in cutting machines. They are simpler and cheaper but tend to wear out faster. They work well for straightforward tasks where high precision is not a priority. Selecting the right motor type can be challenging. Each option has pros and cons, requiring careful consideration for your specific application. It’s essential to weigh these factors to ensure optimal performance.

Cutting machine frames are crucial for ensuring precision and stability. A well-designed frame supports the weight of the machine and reduces vibrations during operation. According to a 2022 industry report, over 40% of cutting errors are attributed to inadequate frame strength. A sturdy frame enables consistent cutting performance and improves overall efficiency.

Choosing the right materials for a cutting machine frame is vital. Steel is commonly used due to its strength, but aluminum is lighter and corrosion-resistant. However, many manufacturers often overlook the importance of material selection. As a result, the longevity of the machine may be compromised. This can lead to increased maintenance costs.

Design elements also play a crucial role. The geometry of the frame impacts the machine's performance. For instance, a poorly designed frame could lead to misalignment. Misalignment can result in defects and waste material. Reports suggest that up to 30% of production can be lost due to such issues. Therefore, scrutinizing the design can yield significant benefits. It is essential to evaluate and reassess frame specifications constantly to ensure optimal functionality and reduce potential risks.

| Part Name | Function | Material | Maintenance Tips |

|---|---|---|---|

| Cutting Head | Holds the cutting tool and directs the cutting mechanism | Steel | Keep clean and replace worn tools |

| Frame | Provides support and stability to the machine | Aluminum or Steel | Regularly check for alignment and fix loose components |

| Motor | Powers the movement of the cutting tool | Carbon Steel & Copper | Ensure proper ventilation and lubricate bearings |

| Guides | Directs the cutting tool and keeps it aligned | Plastic or Metal | Inspect for wear and replace if necessary |

| Belt | Transfers power from the motor to the cutting mechanism | Rubber | Check for tension and replace if frayed |

| Control Panel | Allows user to control machine settings | Plastic | Regularly test buttons and keep it dry |

| Cooling System | Prevents overheating of components during operation | Metal & Plastic | Check for blockages and ensure proper flow |

| Safety Guards | Protects the user from moving parts | Polycarbonate | Ensure they are intact and functional |

| Power Supply | Provides electrical power to the machine | Metal | Check connections and power ratings regularly |

| Base | Holds the entire machine structure | Steel | Inspect for stability and support wear |

Maintaining cutting machine parts is essential for efficiency. Proper care can extend their lifespan. Regular inspection is a must. Check for wear and tear often. Look at blades, belts, and wheels. Small issues can escalate into larger problems.

Cleaning is crucial. Dust and debris can affect performance. Use a soft brush or compressed air. Lubrication is also key. Oil moving parts periodically. This reduces friction and prevents overheating. But remember, over-lubrication can attract dirt.

Sometimes, it’s easy to overlook minor damage. A tiny chip on a blade may seem harmless. Yet, it can cause inaccurate cuts. Address these issues right away. A proactive approach is always better. Regular maintenance pays off in the long run.