As the demand for efficient cooling solutions rises, Atomizing Misting Nozzles have emerged as essential tools. Industry reports indicate that the global cooling market is projected to reach $100 billion by 2026. This rapid growth reflects the increasing need for innovative cooling technologies in various sectors, including agriculture, hospitality, and industrial applications.

Atomizing Misting Nozzles operate by breaking water into tiny droplets. These droplets quickly evaporate, creating a cooling effect. Using high-pressure systems, these nozzles can lower ambient temperatures by up to 30 degrees Fahrenheit. However, not all nozzles are created equal. Some may face challenges regarding durability and performance, especially in harsh environments. Identifying the right product requires careful evaluation.

Many products claim to provide optimal cooling, but true efficiency hinges on proper selection. Knowing which Atomizing Misting Nozzles to use in specific applications can significantly enhance cooling capabilities. As we look towards 2026, the need for reliable and innovative solutions will only grow. Choosing wisely is essential for achieving the best results and ensuring satisfaction.

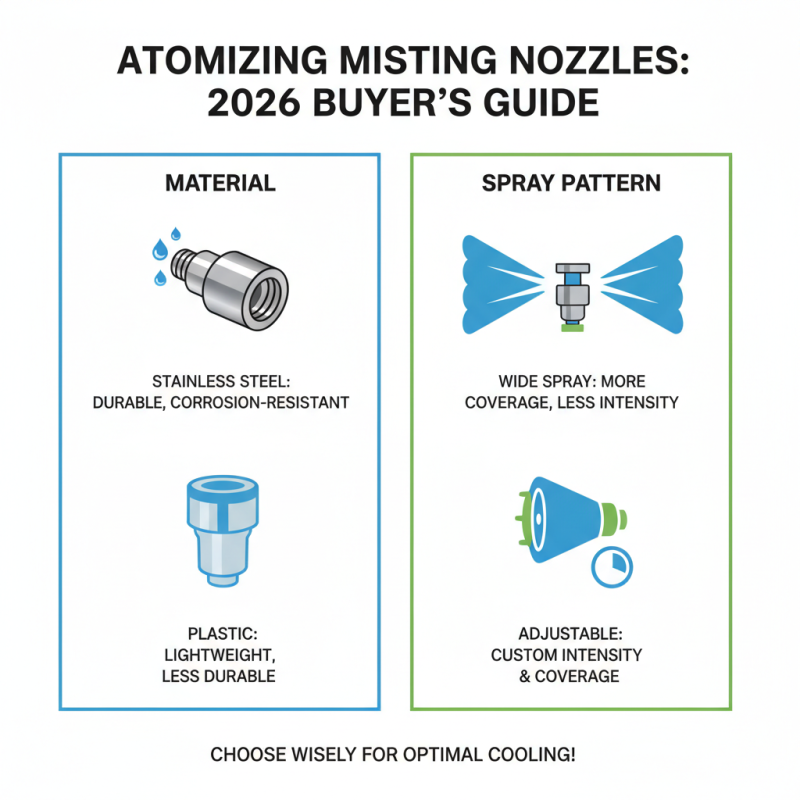

When choosing atomizing misting nozzles in 2026, several features are crucial. The nozzle’s material matters. Stainless steel is strong and resists corrosion. Nozzles made of plastic are lighter but may not last as long. Consider the spray pattern too. A wide spray can cover more area but may provide less intenseness. Adjustable options allow for personal preference in cooling levels.

Another essential feature is the mist size. Smaller droplets evaporate quicker, providing more cooling. Larger droplets may feel heavier and could wet surfaces. Pay attention to installation ease. Some nozzles require complex fixtures while others are simpler. Also, check the water pressure requirements. Misting systems may not function optimally with low water pressure.

Design flexibility is another aspect to consider. Some models offer multi-directional spraying, allowing for better coverage. But this can complicate installation. In practice, the perfect balance of features may vary depending on specific needs. The ideal nozzle for one setting may falter in another.

When it comes to atomizing misting nozzles, there are various types to consider. Each type serves a unique purpose in cooling applications. High-pressure nozzles, for example, operate at pressures above 1000 psi. They produce fine mist droplets, enhancing evaporation. This process efficiently cools the surrounding air. Reports indicate that these nozzles can reduce ambient temperatures by up to 20 degrees Fahrenheit in outdoor settings.

Low-pressure nozzles, on the other hand, require less energy. They function well in residential spaces, offering effective cooling without high power needs. With a pressure range between 30 to 100 psi, they also reduce water consumption significantly. Studies show that using low-pressure systems can save homeowners about 30% on water bills.

Another option is the rotating misting nozzle. This design allows for an adjustable spray pattern. This feature can cover a larger area. Users have noticed that these nozzles often create uneven cooling if not positioned carefully. The installation of misting systems may seem straightforward, yet placement errors might lead to inefficient cooling zones. Prospective buyers should weigh their options carefully, as the wrong choice can hinder performance.

| Nozzle Type | Flow Rate (GPH) | Droplet Size (Microns) | Material | Pressure Range (PSI) |

|---|---|---|---|---|

| Standard Atomizing Nozzle | 1.2 | 50 | Brass | 30-60 |

| High Pressure Mist Nozzle | 0.5 | 10 | Stainless Steel | 70-100 |

| Low Flow Atomizer | 0.8 | 80 | Plastic | 20-40 |

| Fan Mist Nozzle | 1.5 | 60 | Aluminum | 30-50 |

| Adjustable Atomizing Nozzle | 1.0 | 40 | Brass | 20-60 |

| Miniature Misting Nozzle | 0.25 | 100 | Plastic | 10-30 |

| Threaded Atomizing Nozzle | 0.75 | 70 | Stainless Steel | 40-80 |

| Rotary Atomizing Nozzle | 1.8 | 30 | Brass | 50-90 |

| Industrial Misting Nozzle | 2.0 | 20 | Stainless Steel | 80-120 |

| Portable Mist Nozzle | 0.8 | 90 | Plastic | 15-35 |

When considering high-quality misting nozzles in 2026, several key factors come into play. The most important is the material. Nozzles made of durable materials will withstand heat and resist corrosion. Look for options that provide longevity and reliability even in harsh conditions.

Another factor is the nozzle design. Different designs cater to various cooling needs. Some offer wide coverage, while others focus on precision. A good nozzle should atomize water effectively for maximum cooling. Pay attention to the spray pattern. It should be fine enough to evaporate quickly.

Customer feedback is invaluable. You can learn a lot from user experiences. They often highlight aspects like ease of installation or maintenance. Some products may perform well initially but may fade over time. Keep this in mind when choosing the right fit for your needs. A well-chosen nozzle can significantly enhance your outdoor comfort.

When the heat rises, effective atomizing misting nozzles come to the rescue. These nozzles are crucial for outdoor spaces, offering a refreshing solution. However, not all nozzles are created equal. Each design targets a specific need and environment, which can be tricky for users to navigate.

A slight variation in nozzle size can affect cooling efficiency. Smaller nozzles produce finer mist, creating a cooler atmosphere. Larger nozzles may soak surfaces, which can be less desirable. Customers often overlook this detail, ending up with damp patios instead of a refreshing breeze. It’s essential to match the nozzle to your setup.

Installation and maintenance can be challenging too. Users may experience clogging issues over time. Regular cleanings are necessary but often forgotten in busy schedules. Misting systems require thoughtful integration with existing outdoor decor. An aesthetically pleasing setup can enhance the overall experience. Yet, many overlook this aspect, leading to a disjointed look. Choosing the right atomizing misting nozzle involves more than just cooling; it’s about creating an enjoyable outdoor space.

Installing and maintaining misting nozzles can enhance outdoor cooling significantly. A proper setup ensures that users benefit fully from misting systems. A report by the International Society of Misting shows that an efficient misting system can reduce temperatures by up to 20 degrees Fahrenheit in outdoor spaces. This is crucial for creating comfortable environments in hot climates.

Understanding nozzle placement is key. Nozzles should be positioned strategically to maximize coverage. A distance of 10 to 12 feet apart is recommended for optimal mist distribution. Regular maintenance is also essential. Clogged nozzles can reduce effectiveness. According to data from the Misting Research Council, nearly 30% of users face issues due to neglecting regular cleanings. Routine checks ensure that nozzles are free from calcium build-up and dirt.

While setting up a misting system might seem straightforward, users often encounter challenges. Achieving the right water pressure is vital for fine mist production. Insufficient pressure leads to larger droplets, which can be less effective. Ensuring you have the correct pressure gauge can save frustration. Adapting to these needs might require adjustments and careful planning. This level of detail is often overlooked but critical for an efficient misting experience.