In today's manufacturing landscape, the selection of the right Liquid Coating Machine is crucial for achieving optimal production efficiency and quality. As industries increasingly focus on enhancing surface finish and protection, understanding the various factors that influence your choice of coating machinery has never been more important. Whether you are a small business or a large-scale production facility, the right equipment can significantly impact your overall operations, reducing waste, improving throughput, and ensuring consistent results.

This guide aims to equip you with the top ten tips for selecting the best Liquid Coating Machine tailored to your specific needs. From assessing the nature of your products to understanding the technical specifications, each aspect plays a vital role in your decision-making process. By taking the time to evaluate these considerations, you can make informed choices that align with your production goals and enhance your operational efficiencies. Embrace the opportunity to invest wisely in a Liquid Coating Machine that will not only meet your current requirements but also accommodate future growth and innovation in your business.

When selecting a liquid coating machine, understanding your specific coating requirements and specifications is paramount. The type of material you're working with, the viscosity of the liquid, and the desired finish all play crucial roles in determining the right machine for your needs. For instance, if you are working with thicker coatings, you'll need a machine capable of handling such viscosity, ensuring smooth application without clogging.

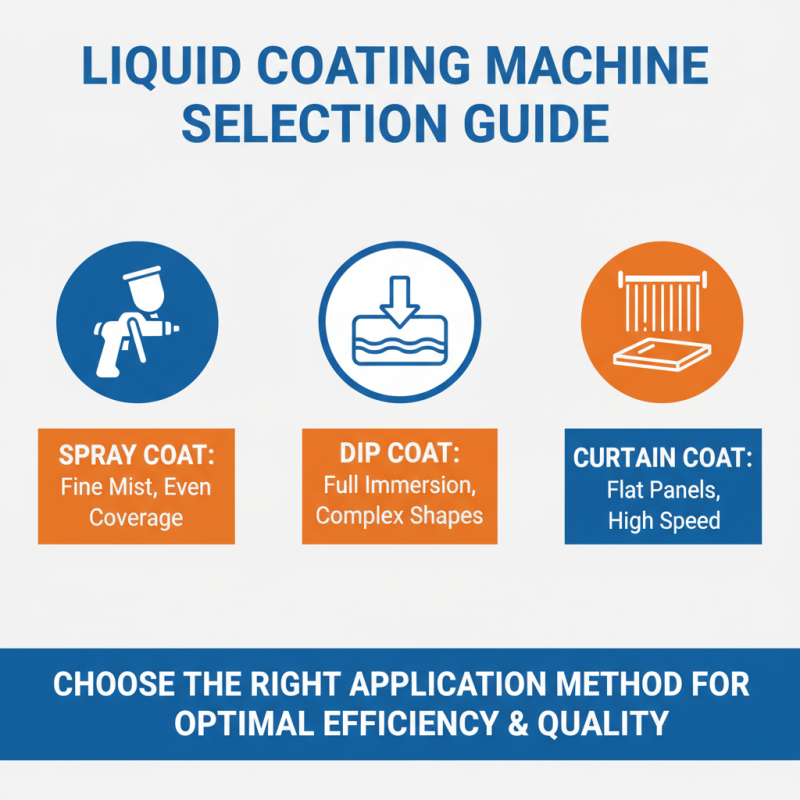

To narrow down your options effectively, it’s essential to evaluate the application method that aligns with your coating goals. Whether you’re considering spray, roll, or dip coating, each method has its own strengths that cater to different requirements. As a tip, conduct thorough tests with different machines to see which one offers the best performance for your specific application. Also, consider the range of adjustable settings a machine offers; flexibility can greatly enhance your overall coating process.

Another vital aspect to consider is the production volume you need to achieve. If you have high throughput requirements, look for machines designed for efficiency and scalability. When assessing capacity, keep in mind maintenance and ease of operation, as a user-friendly machine can significantly reduce downtime. Always remember that investing time in understanding these specifications will lead you to make an informed decision that meets both your operational needs and production goals.

When evaluating different types of liquid coating machines, it's crucial to consider the specific application for which you need the equipment. There are various types of machines available, including airless sprayers, electrostatic sprayers, and conventional air spray systems. Each of these machines operates on unique principles and is suited for different types of coatings and surfaces. For example, airless sprayers are typically used for thicker coatings and provide a fast application, while electrostatic sprayers are ideal for achieving a fine finish on complex shapes, offering better paint adhesion.

Another significant factor to consider is the size and capacity of the machine. Larger machines often have higher throughput, making them suitable for industrial applications, while smaller models may be more appropriate for small-scale projects or detailed work. It's also important to assess the machine's versatility—some machines can accommodate a variety of liquid coatings, while others are designed for specific types. Understanding these differences will help you select a liquid coating machine that meets both your immediate needs and long-term production goals.

When selecting a liquid coating machine, there are several key features to consider to ensure that the equipment aligns with your specific requirements. One crucial aspect is the application method, which can significantly impact the efficiency and quality of the coating process. Machines can vary in their application techniques, including spray, dip, or curtain coat methods. Understanding the specific needs of your project will guide you in choosing a machine that optimally applies the coating material with minimal waste.

Another important feature is the machine's versatility. A liquid coating machine that can accommodate different types of coatings—such as water-based, solvent-based, or UV coatings—will provide greater flexibility for various projects. Additionally, consider the machine’s adjustable settings for parameters like flow rate and pressure. This adaptability allows for fine-tuning, ensuring that you achieve consistent results across diverse applications. Lastly, ease of maintenance and accessibility for cleaning should not be overlooked, as these factors contribute to the longevity and reliability of the machine in the long run.

When selecting a liquid coating machine, assessing the manufacturer’s reputation and customer support options is crucial. A reputable manufacturer typically has a history of reliability and quality in their products. Start by researching customer reviews and testimonials. These insights can provide valuable information about the machine’s performance and the company's responsiveness to issues. Look for manufacturers with a strong presence in the industry and those who have received positive feedback for their after-sales service.

In addition to reputation, consider the customer support options available. A manufacturer that offers extensive support, such as user manuals, troubleshooting guides, and access to knowledgeable technicians, can greatly enhance your experience with the machine. Determine whether they provide training for operators, as this can be a significant benefit in maximizing the machine's potential.

When evaluating options, don't hesitate to reach out to the manufacturer directly with any questions. This will help you gauge their responsiveness and willingness to assist. Identifying a manufacturer who prioritizes customer satisfaction will ensure that your investment is backed by reliable support, enhancing both your operational efficiency and overall satisfaction with the liquid coating process.

| Feature | Consideration | Importance Level | Notes |

|---|---|---|---|

| Manufacturer Reputation | Check reviews and testimonials | High | A reputable manufacturer often ensures quality. |

| Customer Support | Availability of assistance | High | Responsive support can solve issues quickly. |

| Warranty | Length and coverage | Medium | Longer warranties indicate product reliability. |

| Customization Options | Flexibility for specific needs | Medium | Customized machines can improve efficiency. |

| Machine Specifications | Understanding features and capabilities | High | Needs to match production requirements. |

| Maintenance Requirements | Ease of cleaning and upkeep | Medium | Simple maintenance saves time and money. |

| Price | Initial cost vs long-term value | High | Consider total cost of ownership. |

| Production Speed | Output rate of the machine | High | Fast machines improve productivity. |

| Energy Efficiency | Power consumption analysis | Medium | Energy-efficient machines lower costs. |

| User-Friendliness | Ease of operation | Medium | User-friendly machines reduce training time. |

When considering the acquisition of a liquid coating machine, one pivotal aspect to evaluate is the budget. The initial purchase price can vary significantly, but it’s vital to factor in the total cost of ownership over time. While a lower upfront cost may seem appealing, it could lead to higher operational expenses, maintenance fees, and inefficiencies in production. A thorough analysis of these long-term costs can prevent unexpected financial burdens and ensure that the machine aligns with your operational goals.

Additionally, incorporating budget considerations involves assessing the potential return on investment (ROI). Evaluate the machine's efficiency, throughput, and reliability, as these elements impact productivity and profitability. A more advanced machine might have a higher purchase price but could result in lower waste and higher quality outputs, ultimately saving money in the long run. By carefully analyzing both the immediate and future expenditures associated with liquid coating machines, you can make a well-informed decision that supports sustained success in your coating operations.