In the rapidly evolving landscape of manufacturing, the significance of Thin Film Coating Machines has grown tremendously, marking a pivotal shift towards precision and efficiency in various industries. As we approach 2025, industry experts emphasize the need for advanced technology that not only enhances performance but also aligns with sustainable practices. Dr. Emily Carter, a renowned specialist in thin film technology, noted, "The future of Thin Film Coating Machines lies in their ability to integrate seamlessly with smart manufacturing systems, optimizing production while minimizing environmental impact."

With innovations continuously pushing the boundaries of what's possible, understanding current trends and making informed purchasing decisions has never been more critical. As businesses strive to remain competitive, Thin Film Coating Machines will undoubtedly play a crucial role in ensuring superior product quality and operational efficiency. This article aims to provide insights into the top machines of 2025, exploring key trends, technological advancements, and essential features that buyers should consider.

By delving into these elements, stakeholders in the manufacturing sector can better navigate the complex market of Thin Film Coating Machines, equipping themselves with the knowledge necessary to invest wisely and prepare for the future. As we embark on this exploration, the future of thin film technology is not just about machinery; it is about innovation that shapes a more sustainable and efficient manufacturing landscape.

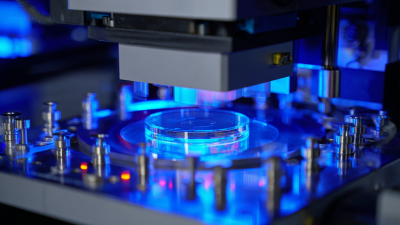

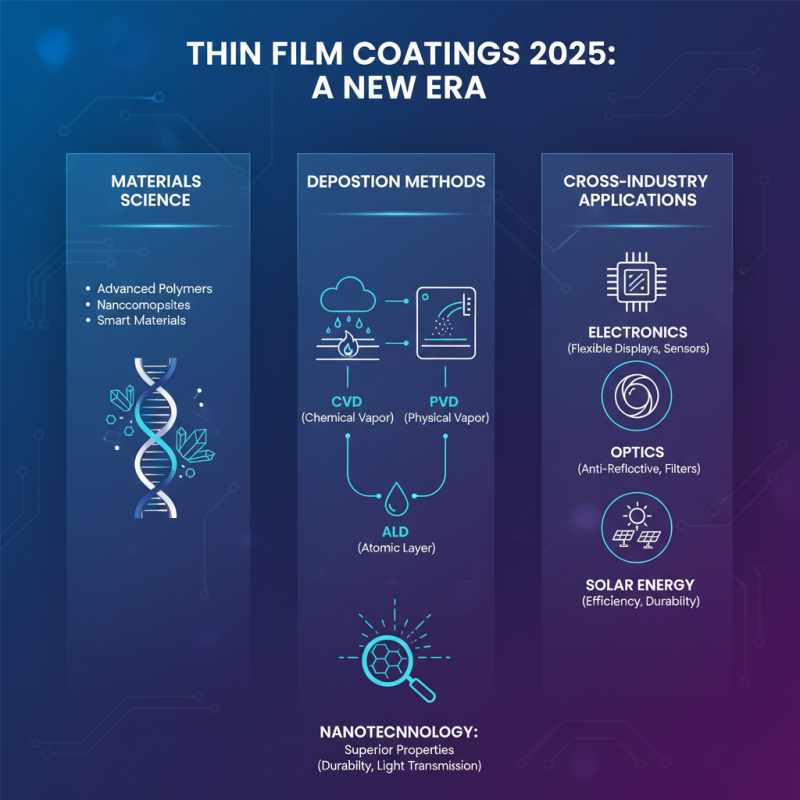

Thin film coating technologies have evolved significantly in 2025, driven by advancements in materials science and deposition methods. These technologies have found applications across various industries, including electronics, optics, and solar energy. In this era, techniques like chemical vapor deposition (CVD) and physical vapor deposition (PVD) are leading the charge, enabling the production of ultra-thin layers with precise control over thickness and composition. Innovations in nanotechnology are also playing a crucial role, allowing for coatings that exhibit superior properties, such as enhanced durability and improved light transmission.

When considering a thin film coating machine, it's essential to evaluate specific features and capabilities. Look for machines that offer versatility in material compatibility, as well as those that support multiple deposition techniques. Keep an eye on scalability, ensuring the equipment can accommodate both small-scale prototypes and large-scale production.

Tips: Always ask about the technical support and training provided by manufacturers. A knowledgeable team can make a significant difference in optimizing machine use. Additionally, consider machine energy efficiency and its impact on overall operational costs, as energy consumption can affect long-term profitability in high-volume processes.

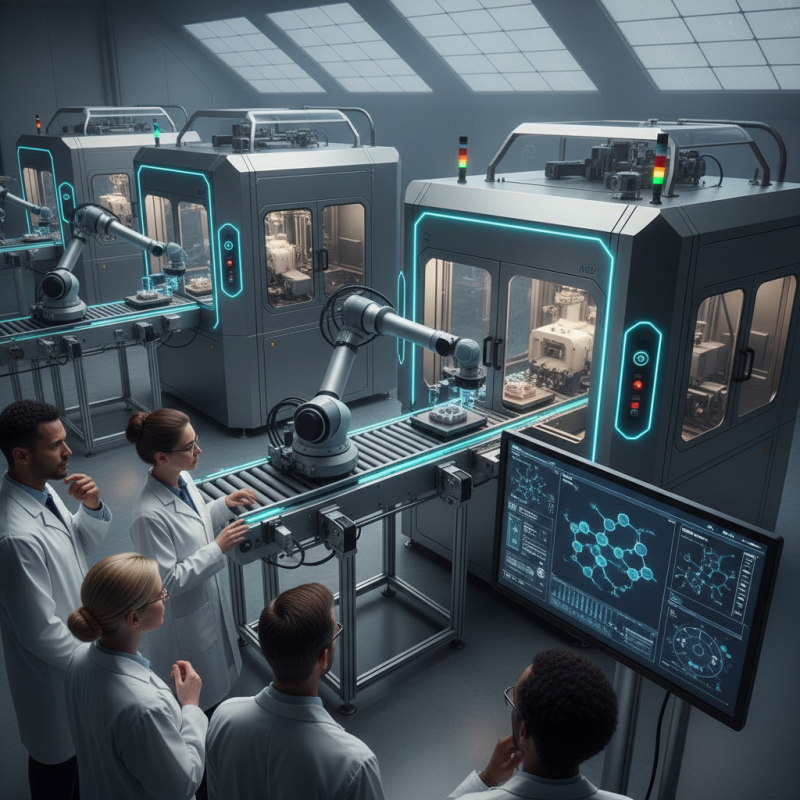

The thin film coating industry is experiencing transformative changes as we move into 2025, driven by advancements in technology and an increasing demand for lightweight, high-performance materials across various sectors. Key trends influencing the industry include automation and digitalization, which significantly enhance production efficiency and precision. According to a recent industry report, the global thin film coating market is projected to reach $17 billion by 2025, highlighting a compound annual growth rate (CAGR) of 8.5% from 2020 to 2025. This growth is propelled by innovations in solar energy technologies and the burgeoning electronics sector, where thin films play a critical role in improving device functionalities.

Sustainability is another prominent trend shaping the thin film coating landscape. Manufacturers are increasingly adopting eco-friendly materials and processes to minimize their environmental footprint. A 2023 statistical analysis indicated that nearly 60% of companies in this sector are investing in greener coating solutions, responding to consumer demand for sustainable products and compliance with stringent environmental regulations. Moreover, advanced deposition techniques, such as Atomic Layer Deposition (ALD) and chemical vapor deposition (CVD), are being utilized to achieve superior film qualities while reducing material waste.

**Tips for Buyers**: When considering thin film coating machines, prioritize those that offer flexibility in application and scalability to meet your production needs. Look for systems equipped with user-friendly interfaces and robust automation features to streamline operations and reduce labor costs. Additionally, pay attention to the machine's compatibility with sustainable materials, which can help you stay ahead in a competitively evolving market.

**Tips for Investment**: It’s beneficial to conduct a thorough market analysis and evaluate emerging technologies in thin film coatings before making a purchase. Engaging with industry experts and attending relevant trade shows can provide valuable insights into the latest innovations and potential partnerships, ensuring a well-informed investment decision.

When considering the purchase of thin film coating machines, several essential features merit careful evaluation to ensure they meet your operational needs. First and foremost, the machine's deposition rate is critical. A higher deposition rate can significantly enhance production efficiency, allowing for faster turnaround times on projects. Look for machines that offer adjustable rates, enabling flexibility to accommodate various types of coatings and substrates.

Another important aspect to consider is the type of coating technology employed. Different technologies, such as thermal evaporation, sputtering, or chemical vapor deposition, each have distinct advantages and applications. Understanding these methods and aligning them with your specific requirements will help you make an informed decision. Additionally, factors like substrate compatibility, uniformity of coating thickness, and process control capabilities are vital for achieving high-quality results. Strong monitoring and automation features can streamline operations and reduce the potential for errors during the coating process.

Lastly, don't overlook the importance of maintenance and support. A machine that is easy to maintain and comes with robust technical support can save time and resources in the long run. Assess the availability of replacement parts, ease of service, and the overall reliability of the system. By focusing on these features, you'll be better equipped to select a thin film coating machine that maximizes your investment and meets your production goals.

In 2025, the landscape of thin film coating machines is evolving rapidly, driven by advancements in technology and growing industry demand. The market is expected to showcase a diverse range of models that cater to various applications, from optoelectronics to solar energy and medical devices. Leading manufacturers are focusing on enhanced precision, speed, and energy efficiency, ensuring that their thin film coating machines meet the stringent requirements of modern production processes.

Among the top models anticipated in 2025, several are designed to support advanced techniques such as atomic layer deposition (ALD) and Chemical Vapor Deposition (CVD). These machines are equipped with cutting-edge automation for improved consistency and reduced human error in production. Users are increasingly leaning towards systems that offer flexibility in substrate sizes and materials, enabling them to adapt quickly to changing market demands.

The integration of smart technology and IoT capabilities in new models will further streamline operations, allowing for real-time monitoring and maintenance, thus enhancing productivity across various sectors.

The landscape of thin film coating technologies is poised for significant advancements in the coming years. Innovations are driven by the demand for more efficient, versatile, and environmentally friendly coating solutions across various industries, including electronics, optics, and renewable energy. Emerging techniques such as atomic layer deposition (ALD) and advanced sputtering methods are leading the charge, allowing for precise control over film thickness and composition, resulting in enhanced material properties.

Moreover, the integration of artificial intelligence and machine learning into the design and operational processes of thin film coating machines is expected to revolutionize the industry. These advancements facilitate real-time monitoring and adjustment of coating parameters, significantly improving yields and reducing waste. As industries increasingly adopt sustainable practices, the focus on green technologies in thin film deposition processes will also be paramount, paving the way for coatings that require less energy and generate fewer emissions while maintaining high performance standards.

| Machine Type | Coating Method | Target Industries | Max Coating Speed (m²/h) | Notable Features |

|---|---|---|---|---|

| Batch Coater | CVD | Electronics, Optics | 50 | High precision, customizable |

| Roll-to-Roll Coater | PEVD | Solar, Flexible Electronics | 100 | High throughput, scalability |

| Desktop Coater | sputter deposition | Research, Prototyping | 20 | Compact, user-friendly |

| High Vacuum Coater | PVD | Architecture, Glass Coatings | 30 | Optical range, multi-layer |

| Atmospheric Coater | Deposition | Automotive, Electronics | 40 | Eco-friendly, low waste |