In the rapidly evolving field of cardiovascular devices, the performance and reliability of stents are paramount. As procedures become more complex and patient outcomes are scrutinized, the role of the Stent Coating Machine cannot be overstated. Dr. Emily Hartman, a leading expert in biomedical engineering, emphasizes this sentiment by stating, "The advancement of stent coating technologies will ultimately determine the success of minimally invasive cardiovascular interventions."

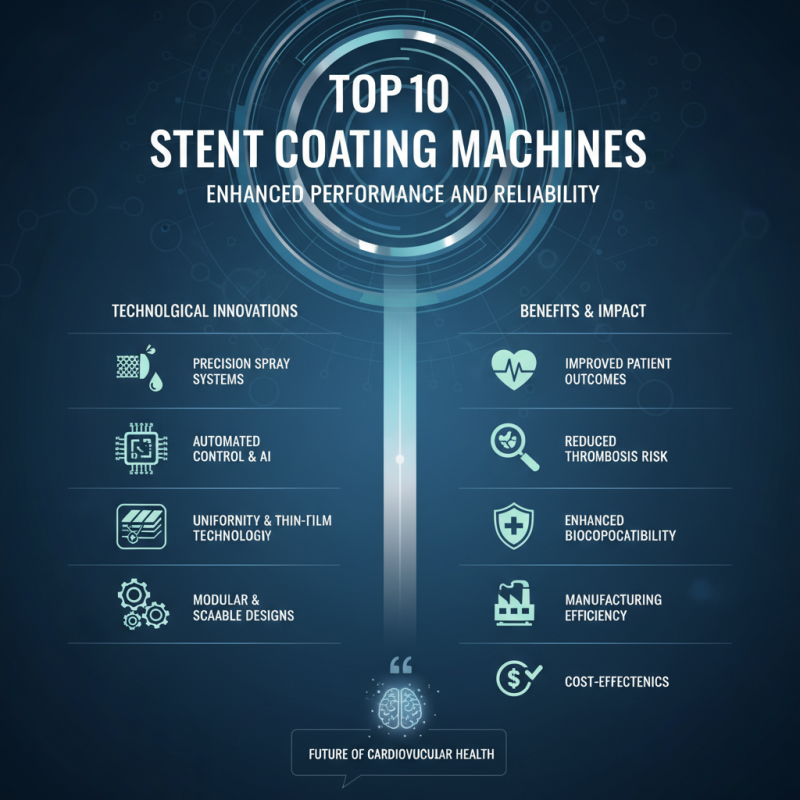

With the rise of sophisticated techniques and materials, the demand for effective stent coating machines has surged. These machines are essential for providing a uniform and high-quality coating on stents, which plays a crucial role in preventing thrombosis and ensuring biocompatibility. In this article, we will explore the top 10 stent coating machines that stand out in delivering enhanced performance and reliability, focusing on their technological innovations and the benefits they offer to manufacturers and healthcare providers alike. As we delve into the features and functionalities of these machines, it becomes clear that the future of cardiovascular health hinges on advancements in stent coating technology.

Stent coating technology plays a crucial role in the development of medical devices, significantly impacting the performance and reliability of stents used in various vascular treatments. The coatings are designed to enhance biocompatibility, reduce restenosis, and improve drug delivery mechanisms. According to a report by the Global Stent Coating Market, the demand for advanced stent coatings is projected to grow at a compound annual growth rate (CAGR) of around 8.5% over the next five years. This growth underscores the increasing emphasis on optimizing stent performance through enhanced coating techniques.

The importance of stent coating extends beyond mere functionality. Coatings can dictate the interaction between the stent and the biological environment, aiming to minimize inflammatory responses and promote faster healing times. Advanced materials and technologies, such as polymeric and metallic coatings, are being explored to tailor the properties of stents to better suit patient needs. Recent studies have shown that stents with enhanced coatings can lead to a 30% reduction in restenosis rates when compared to bare-metal stents, highlighting the efficacy of these advancements.

Tips: When exploring stent coating options, consider the specific clinical requirements and potential patient reactions. Additionally, staying informed on the latest technological advancements can lead to better decision-making in selecting the most reliable stent systems. As the market evolves, continuing education on new materials and applications will be integral for healthcare professionals involved in vascular interventions.

When selecting a stent coating machine, several key features significantly impact performance and reliability. Firstly, precision in coating application is crucial. Machines should employ advanced technologies, such as automated dispensing systems, to ensure consistent and accurate application of coating materials. This not only enhances the quality of the stents but also minimizes waste, ensuring that resources are used efficiently.

Another important aspect to consider is the versatility of the machine. A good stent coating machine should accommodate various stent designs and materials, allowing manufacturers to adjust settings and configurations easily for different production runs. Flexibility in operation helps companies stay competitive and responsive to market demands while promoting innovation in stent design.

Lastly, strong maintenance and support capabilities are essential for reliable operation. Machines should be designed for easy cleaning and maintenance to minimize downtime. Additionally, robust customer support and after-sales service can help address technical issues swiftly, ensuring that the manufacturing process remains uninterrupted. These features together contribute to enhanced performance and reliability in stent coating machines, making them vital investments for medical device manufacturers.

The development of stent coating machines has significantly advanced the capabilities of medical device manufacturing, particularly in the production of drug-eluting stents. According to a recent report by Research and Markets, the global market for medical coating devices is set to reach $3.5 billion by 2025, illustrating the increasing demand for enhanced performance and reliability in stent production. This growth is driven by the necessity for precision, uniformity, and effectiveness in coating technologies, which directly impact the therapeutic outcomes of stent procedures.

When evaluating the top stent coating machines available, several key factors are crucial for comparison. These include coating thickness control, application method efficiency, drying technologies, as well as automation levels. For instance, studies have shown that machines utilizing advanced spray technologies can achieve a coating uniformity variance of less than 5%, significantly improving the reliability of drug delivery systems. Additionally, an emphasis on automated processes not only reduces human error but also enhances production throughput, crucial for meeting the growing demand within the healthcare industry. With advancements like these, the right stent coating machine can lead to improved patient outcomes and more effective cardiovascular interventions.

| Rank | Machine Model | Coating Technology | Coating Speed (mm/min) | Temperature Control (°C) | Ease of Use | Cost (USD) |

|---|---|---|---|---|---|---|

| 1 | Model A | Electrostatic Spraying | 150 | 30 | High | 25,000 |

| 2 | Model B | Spray Coating | 200 | 25 | Medium | 30,000 |

| 3 | Model C | Dip Coating | 120 | 35 | High | 20,000 |

| 4 | Model D | Spray Coating | 180 | 28 | Medium | 28,500 |

| 5 | Model E | Electrostatic Spraying | 160 | 32 | High | 22,000 |

| 6 | Model F | Dip Coating | 130 | 30 | Medium | 18,000 |

| 7 | Model G | Spray Coating | 210 | 28 | High | 26,000 |

| 8 | Model H | Electrostatic Spraying | 140 | 29 | Medium | 24,000 |

| 9 | Model I | Dip Coating | 125 | 34 | High | 19,500 |

| 10 | Model J | Spray Coating | 190 | 27 | Medium | 27,000 |

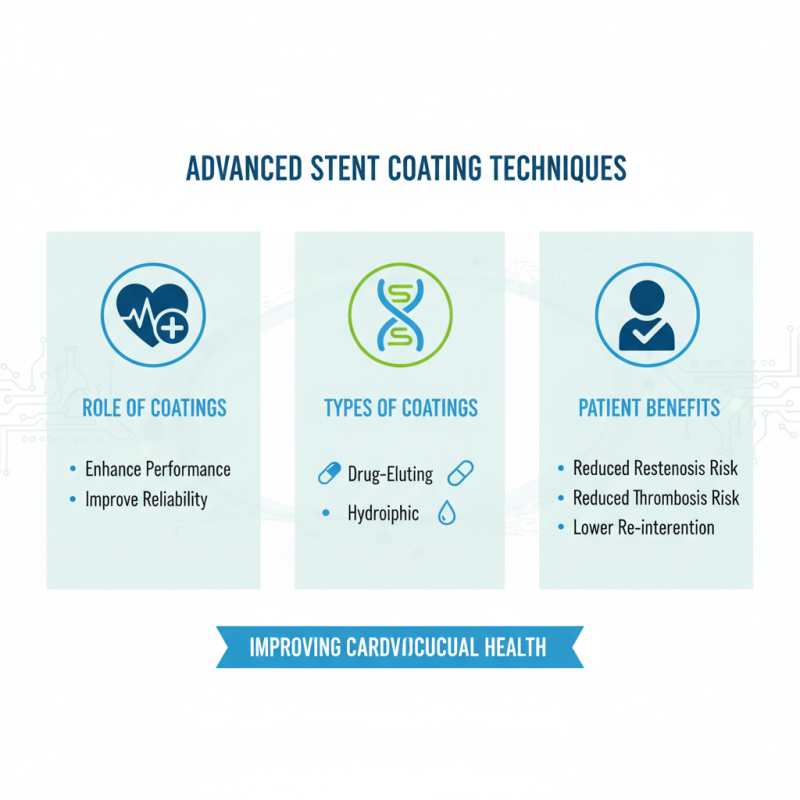

Advanced coating techniques play a crucial role in enhancing the performance and reliability of stents, which are vital in treating cardiovascular diseases. These coating processes involve the application of biocompatible materials that improve the interaction between the stent and the biological environment. By utilizing innovative methods such as drug-eluting and hydrophilic coatings, manufacturers can significantly reduce the risk of restenosis and thrombosis, which are common complications following stent placement. This leads to improved patient outcomes and a lower rate of re-intervention, ultimately benefiting both patients and healthcare providers.

Furthermore, the application of advanced coatings contributes to better mechanical properties of stents. For instance, coatings can enhance the flexibility and strength of the stent, making it easier to navigate through complex vascular pathways during procedures. Improved adhesion and durability of the coatings also minimize the likelihood of wear and degradation over time, ensuring long-lasting performance. As a result, the combination of exceptional coating techniques not only boosts the efficacy of stent performance but also promotes the reliability necessary for long-term patient care.

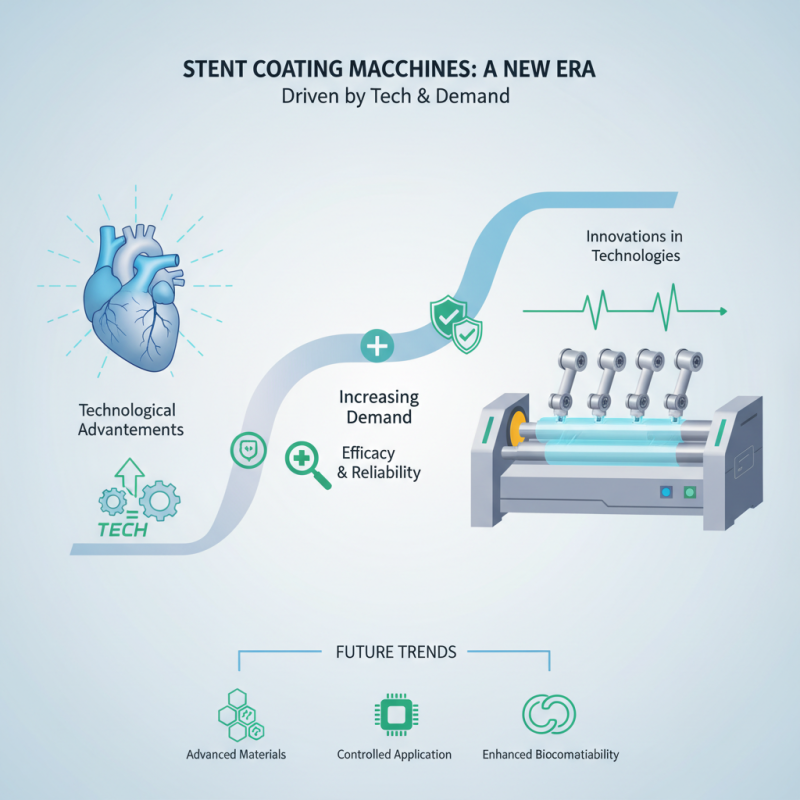

The landscape of stent coating machines is rapidly evolving, driven by advancements in technology and increasing demand for high-performance medical devices. As the healthcare sector places more emphasis on enhancing the efficacy and reliability of stents, innovations in coating technologies are becoming pivotal. Future trends point towards the integration of advanced materials and technologies that enable a more uniform and controlled application of coatings, minimizing inconsistencies and enhancing the biocompatibility of stents.

One of the noteworthy trends is the incorporation of automation and AI into the production processes of stent coating machines. These technologies facilitate real-time quality control, ensuring that every stent meets stringent safety and performance standards. Moreover, the implementation of smart sensors and data analytics can optimize the coating process by providing valuable insights into equipment performance and material properties. This shift not only improves operational efficiency but also supports the development of customized solutions tailored to specific medical needs, paving the way for more sophisticated stent designs in the future.