Spray Coating Equipment is essential in various industries. It ensures a uniform layer on surfaces, enhancing durability and appearance. This equipment uses a spray system to apply coatings smoothly. Users often appreciate its efficiency and versatility.

The operation of spray coating involves precise techniques. A range of materials can be used with this equipment, from paint to protective coatings. However, mastering its use may require practice. Many newcomers face challenges in achieving an even finish. It's a learning process that demands patience and skill.

Investing in quality spray coating equipment is crucial. Selecting the right type impacts the final outcome. Users should be mindful of maintenance to prolong their equipment's life. Regular checks are necessary to avoid issues down the line. While the technology evolves, continuous learning remains vital in this field.

Spray coating equipment is essential in various industries. It applies a thin layer of material onto surfaces. This equipment includes a spray gun, compressor, and a paint reservoir. The spray gun atomizes the coating material, turning it into fine droplets. These droplets create a smooth, even finish on the surface.

The process requires precision. Operators must control the spray pattern and pressure. Inconsistencies can lead to uneven layers or drips. It’s not uncommon for beginners to struggle with achieving the right balance. This learning curve can be frustrating, but it is part of the journey to mastering spray coating.

Materials used in spray coating vary widely. They can include paints, primers, and specialized coatings. Depending on the application, the choice of material and technique can affect the final result. Sometimes, a lack of attention to detail can result in defects. Operators must be vigilant to avoid such pitfalls.

This bar chart illustrates the distribution of spray coating equipment usage across various industries. Automotive leads with 30%, followed by aerospace and electronics. This data helps understand where spray coatings are most commonly utilized.

Spray coating equipment comes in various types, each serving unique purposes. Air spray guns are common in many industries. They use compressed air to atomize the coating material, creating a fine mist. This mist coats surfaces evenly. However, achieving perfect coverage can be challenging. Operators must maintain an optimal distance from the surface.

Another type is the airless spray system. It relies on high pressure to deliver materials without air atomization. This method allows for thicker coatings and can be faster. Yet, it requires careful handling. Overspray can be a major issue, leading to wasted materials and uneven application. Practicing on test surfaces is essential.

Electrostatic spray guns utilize electrical charges. They attract the coating material to the surface, enhancing uniformity. However, achieving the right charge is tricky. If not done correctly, it can result in drips or uneven layers. Each type of spray coating equipment has benefits and drawbacks. Understanding these nuances helps operators make informed choices.

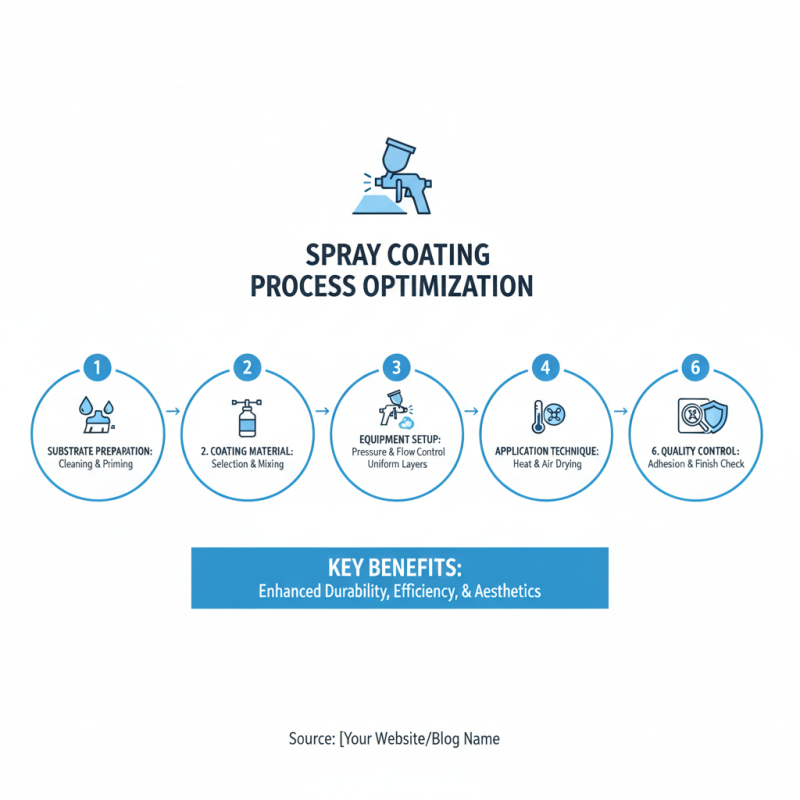

Spray coating equipment is essential in various industries. Understanding how it works can help users optimize their projects. The process begins with the preparation of the substrate. This could involve cleaning and priming the surface to ensure adhesion. Any dust or grease must be removed effectively.

Next, the coating material is loaded into the spray gun. The user must choose the right viscosity and type of coating. This choice impacts the finish quality. A poorly mixed coating can lead to uneven application. Once the material is ready, the spray gun uses compressed air or an electric pump to atomize it. This creates tiny droplets for even spraying.

Users should maintain a steady hand and the right distance from the surface. Over-spraying can cause drips. It's essential to practice and adjust technique as needed. Even experienced users face challenges, such as adjusting for wind during outdoor applications. Reflection on these aspects often leads to improvements in future projects.

Spray coating technology has diverse applications across various industries. This technique is used in automotive, aerospace, and construction sectors, among others. It enables a uniform application of materials on surfaces, which is crucial for performance and durability. Industries often rely on spray coating to enhance protective qualities and aesthetic appeal.

In the automotive industry, spray coating is vital for both protection and appearance. It provides a weather-resistant finish that can withstand harsh conditions. Often, the coating involves multiple layers to ensure durability. It can be a bit tricky; if applied too thickly, it may run or unevenly coat the surface.

In construction, this technology applies to insulation and roofing materials. Spray foam and coatings can seal gaps, improving energy efficiency. Proper technique is essential for effectiveness. An improper spray angle can lead to waste. Metered control systems help reduce such errors.

Tips: Always practice spray techniques on a sample first. This helps in understanding the flow and thickness. Frequent cleaning of equipment ensures longevity and quality of work. Regular maintenance of the spray setting can prevent future mishaps.

| Equipment Type | Functionality | Applications | Advantages |

|---|---|---|---|

| Airless Spray Gun | Delivers high pressure, atomizing paint without air | Industrial coatings, residential painting | Faster application, reduced overspray |

| HVLP Spray Gun | Uses high volume and low pressure to minimize overspray | Automotive refinishing, furniture finishes | Fine finish, efficient material usage |

| Electrostatic Spray Gun | Applies an electric charge to paint particles for better adhesion | Metal surfaces, non-porous materials | Uniform coating, reduced waste |

| Robotic Spray Systems | Automated painting for efficiency and consistency | Manufacturing, automotive assembly lines | High precision, reduced labor costs |

| Air-Assisted Airless Gun | Combines airless and air-assisted technologies for versatility | Heavy-duty industrial applications, large surfaces | Fast application, excellent coverage |

Spray coating equipment has gained widespread popularity across various industries due to its efficiency and versatility. This technique allows for the uniform application of coatings on different surfaces, ranging from metals to plastics. According to a recent market report, the global spray coating equipment market is projected to reach $15 billion by 2025. This growth is driven by its increasing use in automotive, aerospace, and manufacturing sectors.

One key benefit of spray coating is its ability to reduce material waste. Traditional methods often result in overspray and excess use of coatings. In contrast, spray systems can achieve over 95% transfer efficiency. This improvement translates to significant cost savings. Additionally, the technology enhances product quality. Coatings applied through spray methods tend to provide a more consistent finish. However, it’s important to note that improper technique can lead to issues like uneven layers.

Another advantage lies in the adaptability of spray coating systems. They can be tailored for various applications, from thin films to thicker protective layers. Industries report that using spray coating can decrease processing time dramatically. Yet, challenges remain, such as the need for skilled operators. Poor training can lead to subpar outcomes. Hence, investment in comprehensive training is crucial for optimizing the benefits of spray coating technology.