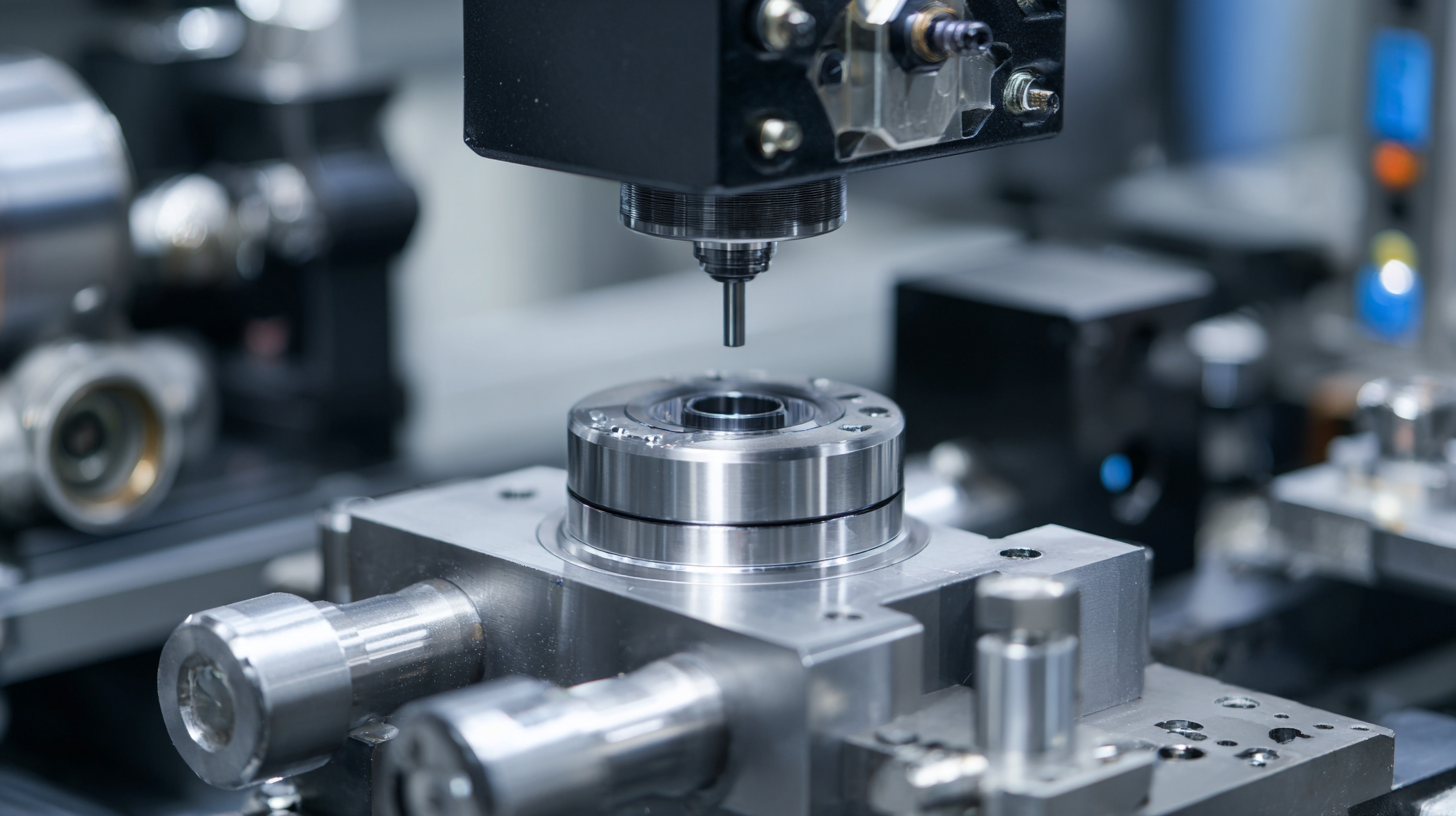

The eyewear industry is undergoing a transformative shift as advancements in technology enhance production capabilities, particularly in the area of lens fabrication. The introduction of state-of-the-art lens coating machines is revolutionizing the precision engineering of eyewear, ensuring higher quality and efficiency in manufacturing. According to the Global Eyewear Market report, the demand for eyewear is projected to reach $200 billion by 2025, driven by increasing consumer awareness of eye health and fashion trends. A crucial component in this growth is the capability of modern Lens Coating Machines, which improve the performance of lenses by applying anti-reflective, anti-scratch, and UV-protection coatings with unmatched accuracy. As the industry seeks to meet the rising consumer expectations for durability and style, the significance of innovative lens coating solutions becomes paramount, positioning manufacturers who adopt these technologies at the forefront of the market.

The evolution of lens coating technology is pivotal in revolutionizing eyewear production, merging precision engineering with innovative solutions. Recent advancements, such as new hard coatings for ophthalmic lenses, illustrate the industry's shift towards high-performance materials that enhance durability without compromising clarity. These coatings not only improve scratch resistance but also contribute to the overall user experience, making eyewear more functional and appealing.

Additionally, the integration of eco-friendly practices in coating processes is gaining traction. Technologies that combine resin molding and surface finishing are not only streamlining production but also reducing waste. Innovations like customizable coatings provide brands with the flexibility to meet diverse consumer demands while maintaining a commitment to sustainability. As the landscape of optical manufacturing continues to evolve, it is evident that advanced coating technologies will play a crucial role in setting new industry standards for quality and environmental responsibility.

| Dimension | Description | Value |

|---|---|---|

| Coating Thickness | Precision of lens coating application | 12-30 microns |

| Production Speed | Average number of lenses coated per hour | 200 lenses/hour |

| Machine Dimensions | Overall size of the coating machine | 1.5m x 1.2m x 1.0m |

| Control System | Type of system used for operation | Digital touch control |

| Energy Consumption | Average power used during operation | 3.5 kWh |

| Weight | Total weight of the machine | 450 kg |

| Warranty Period | Duration of warranty offered | 2 years |

The eyewear manufacturing industry is experiencing a significant transformation driven by advancements in precision engineering. According to a report by Grand View Research, the global eyewear market is expected to reach USD 178.95 billion by 2025, growing at a compound annual growth rate (CAGR) of 8.0%. This growth is partly attributed to the innovative technologies reshaping the production processes, particularly lens coating machines that enhance precision and efficiency.

Modern lens coating machines are equipped with advanced systems that ensure a flawless application of coatings, significantly improving product quality and reducing waste. For instance, a study indicated that implementing automated lens coating technology can decrease production times by up to 30%, while simultaneously boosting the accuracy of coatings applied. This level of precision not only meets the stringent quality standards of the industry but also addresses consumer demands for high-performance eyewear that offers both functionality and aesthetic appeal. As manufacturers invest in these cutting-edge technologies, the potential for customization and production scalability becomes more accessible, ultimately reshaping the future of eyewear manufacturing.

The advent of next-generation lens coating machines is set to revolutionize the eyewear production industry, offering remarkable precision and efficiency. Key features of these advanced machines include automated coating processes that significantly reduce human error. According to a recent report by ResearchAndMarkets, the global eyewear market is expected to reach $180 billion by 2025, and precision engineering will be crucial in meeting this rising demand. The integration of AI and machine learning in the lens coating machines allows for real-time monitoring and adjustments, ensuring that every lens meets the highest standards of quality.

Another significant feature is the capability to apply multiple coatings simultaneously, which enhances productivity. A report by Grand View Research indicated that the demand for anti-reflective and blue-light filtering coatings is surging, as consumers become more aware of eye health. These next-gen machines are designed to accommodate such applications, using advanced materials and techniques that maximize durability and performance. With enhanced coating uniformity and faster processing times, manufacturers can better position themselves in a competitive market while adhering to stringent regulatory standards.

The advancement of automated coating solutions in eyewear production brings a multitude of benefits that significantly enhance both efficiency and product quality. By implementing sophisticated lens coating machines, manufacturers can achieve a level of precision that surpasses traditional methods. These machines are designed to uniformly apply coatings, reducing the likelihood of defects such as bubbles or uneven surfaces, which are common issues in manual processes.

Moreover, automated coating solutions streamline the production workflow, allowing for quicker turnaround times. With the ability to perform multiple coatings in a single cycle, eyewear producers can increase their output while maintaining high standards of quality. This efficiency not only satisfies consumer demand but also contributes to cost savings by minimizing material waste and labor costs. Overall, the integration of advanced coating technology into eyewear manufacturing is a game changer, pushing the boundaries of design and functionality.

The eyewear industry is experiencing a significant transformation, especially in lens coating technologies. With the global eyewear market projected to reach $178.9 billion by 2023, driven by increasing consumer demand for advanced optical products, innovation in lens coatings has never been more crucial. Recent advancements in coating technologies, such as hydrophobic, anti-reflective, and scratch-resistant coatings, are redefining durability and functionality in eyewear. According to a report from Grand View Research, the demand for anti-reflective coatings alone is expected to expand at a CAGR of 7.5% during the upcoming years, highlighting its importance in enhancing user experience.

Future trends indicate a shift towards more sustainable and intelligent lens coating solutions. As manufacturers focus on reducing environmental impact, eco-friendly coatings and materials are becoming increasingly prevalent. Moreover, the integration of digital capabilities, such as smart coatings that adapt to varying conditions, exemplifies the cutting-edge direction of eyewear technology. According to a recent study by Mordor Intelligence, the market for smart eyewear is projected to grow by 17.5% CAGR through 2027, emphasizing the growing consumer appetite for innovation. As the industry moves forward, embracing these trends will be essential for manufacturers striving to stay competitive in the evolving eyewear landscape.