In the evolving landscape of medical device manufacturing, the efficiency and performance of the Stent Coating Machine have become critical factors for success. Recent industry reports indicate that the global stent market is projected to reach $10.52 billion by 2025, driven by the increasing prevalence of cardiovascular diseases and the growing demand for minimally invasive procedures. As manufacturers strive to meet these demands, optimizing the Stent Coating Machine becomes essential for improving product quality and reducing production costs. Enhanced machine performance not only ensures superior coating uniformity and adhesion but also minimizes operational downtime, leading to increased throughput. Implementing advanced technologies and best practices in stent coating processes can thus significantly affect a company's competitive edge in this highly regulated and rapidly growing market.

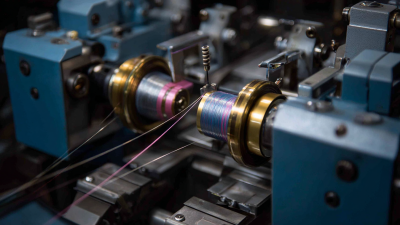

Optimizing stent coating machine parameters is crucial for enhancing material application rates, which ultimately contributes to the performance and reliability of cardiovascular interventions. By adjusting parameters such as coating thickness, drying times, and spray patterns, manufacturers can achieve uniform coatings that improve the biocompatibility and drug-eluting properties of stents. This optimization not only increases the efficiency of the coating process but also enhances the overall effectiveness of the stent in preventing restenosis and promoting healing.

In addition, techniques like alumina sandblasting combined with platinum sputtering have shown promise in improving the surface characteristics of PEEK implants. This surface treatment enhances stability and promotes better cell adhesion, leading to more successful long-term outcomes. The integration of advanced coating technologies into the manufacturing process of vascular bioresorbable stents and other cardiovascular devices represents a significant leap forward in medical device innovation, ensuring that patients receive safer and more effective treatment options.

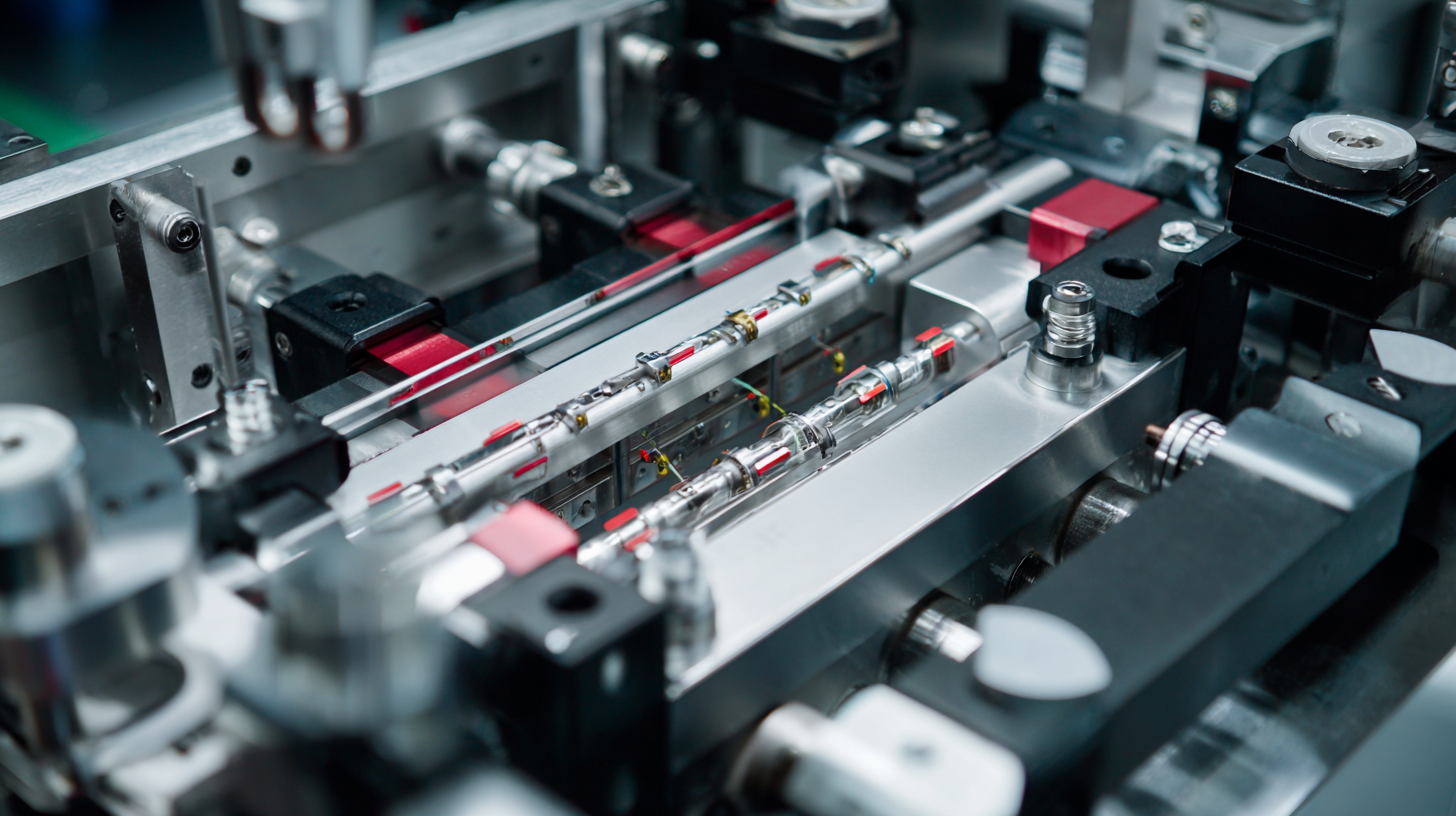

Optimizing temperature control settings in stent coating machines is critical for enhancing polymer adhesion and ensuring coating consistency. According to a report by Grand View Research, the global stent market is projected to reach $12.1 billion by 2025, underscoring the need for advanced manufacturing techniques that ensure product reliability. One of the key factors influencing coating quality is the temperature used during the polymer application process. Studies have shown that maintaining optimal temperatures can significantly reduce the risk of defects, which is essential in achieving the stringent regulatory compliance required in the medical device industry.

Optimizing temperature control settings in stent coating machines is critical for enhancing polymer adhesion and ensuring coating consistency. According to a report by Grand View Research, the global stent market is projected to reach $12.1 billion by 2025, underscoring the need for advanced manufacturing techniques that ensure product reliability. One of the key factors influencing coating quality is the temperature used during the polymer application process. Studies have shown that maintaining optimal temperatures can significantly reduce the risk of defects, which is essential in achieving the stringent regulatory compliance required in the medical device industry.

Adjustments in temperature control settings can lead to more uniform polymer layers, which are vital for the performance of drug-eluting stents. Research indicates that a temperature deviation as small as 5°C can result in a 20% variance in adhesion strength. This inconsistency can not only impair the therapeutic efficacy of the stent but also increase the likelihood of stent thrombosis, a serious complication. Therefore, meticulous calibration of temperature settings, combined with real-time monitoring, can enhance production quality and efficiency, ultimately contributing to improved patient outcomes and reducing costs associated with product recalls and failures.

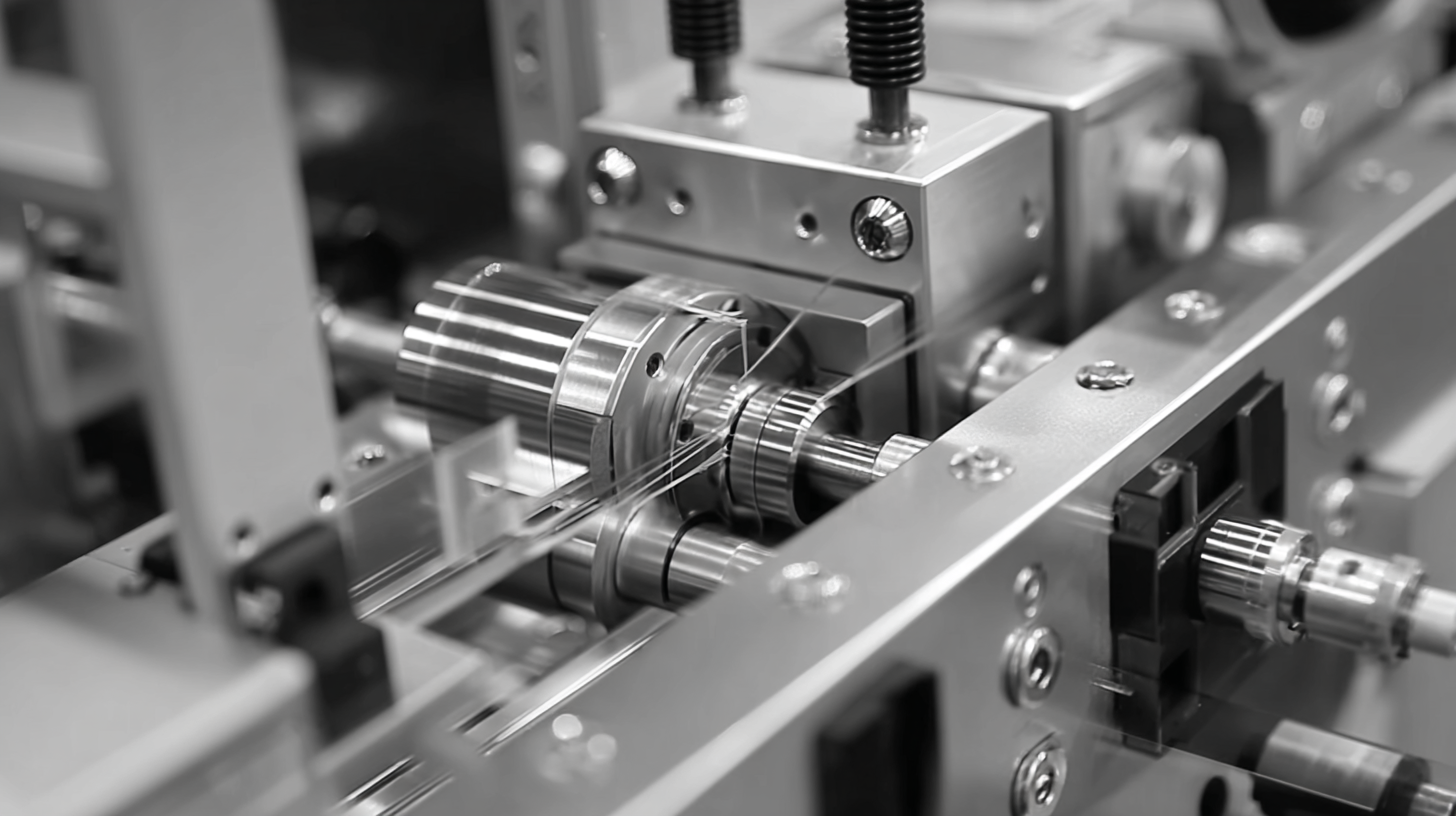

Real-time monitoring systems play a crucial role in optimizing stent coating machines by providing immediate feedback on various parameters throughout the coating process. By integrating sensors that track temperature, viscosity, and coating thickness, operators can identify deviations from the desired specifications in real-time. This immediate visibility allows for prompt adjustments, ensuring that the coating adheres uniformly and optimally to the stents, thereby enhancing the overall performance of the machine.

Furthermore, the utilization of data analytics within these monitoring systems enables a deeper understanding of the coating process. Historical data can be analyzed to identify trends, predict maintenance needs, and recommend process adjustments. This not only increases efficiency by minimizing downtime but also enhances process transparency, facilitating better decision-making. By employing real-time monitoring technologies, manufacturers can achieve higher quality coatings and boost production efficiency, ultimately leading to improved patient outcomes and greater competitive advantage in the medical device industry.

Predictive maintenance strategies are essential for optimizing stent coating machines, as they can significantly reduce downtime and enhance productivity. By integrating advanced sensors and data analytics, manufacturers can monitor the health and performance of their machines in real-time. This proactive approach allows operators to detect potential issues before they lead to equipment failure, minimizing unplanned outages and maximizing operational efficiency. As stent coating machines require precision and reliability, the implementation of predictive maintenance can lead to consistent output quality and improved operational workflows.

Furthermore, the rise of artificial intelligence and machine learning in manufacturing is revolutionizing predictive maintenance practices. These technologies enable machines to learn from operational data, thereby predicting maintenance needs with greater accuracy. This not only helps in optimizing the maintenance schedule but also reduces labor costs associated with manual monitoring. As a result, manufacturers can focus on enhancing performance and achieving better throughput, ultimately contributing to a more efficient production environment in the stent coating process.

Selecting the right stent coating materials is crucial for the success of vascular interventions. Biocompatibility and performance metrics should be the primary considerations when choosing these materials. Biocompatible coatings minimize inflammatory responses and enhance tissue integration, reducing the risk of thrombosis and improving patient outcomes. It's essential to evaluate the mechanical properties and degradation rates of these materials, ensuring they maintain stability and functionality under physiological conditions.

Tips: When choosing a stent coating, prioritize materials that have been thoroughly tested in clinical settings. Look for coatings that demonstrate favorable interactions with endothelial cells and support rapid healing. Additionally, consider the use of bioactive compounds in the coatings that may promote cellular proliferation and integration.

Furthermore, performance metrics should include drug release kinetics if a drug-eluting stent is involved. Ensure that the chosen materials can deliver therapeutic agents efficiently while controlling their release rates to optimize the therapeutic effect. Testing various formulations in simulated physiological environments can yield valuable insights into how these materials will perform in real-world applications.

Tips: Collaborate with material scientists to fine-tune your coating formulations, and invest in advanced testing methods such as in vitro and in vivo studies to assess performance over time.

| Material Type | Biocompatibility Rating | Mechanical Strength (MPa) | Thrombogenicity Score | Coating Thickness (μm) |

|---|---|---|---|---|

| Polymer A | High | 50 | Low | 10 |

| Metal B | Medium | 200 | Medium | 15 |

| Coating C | High | 100 | Very Low | 8 |

| Composite D | High | 150 | Low | 12 |