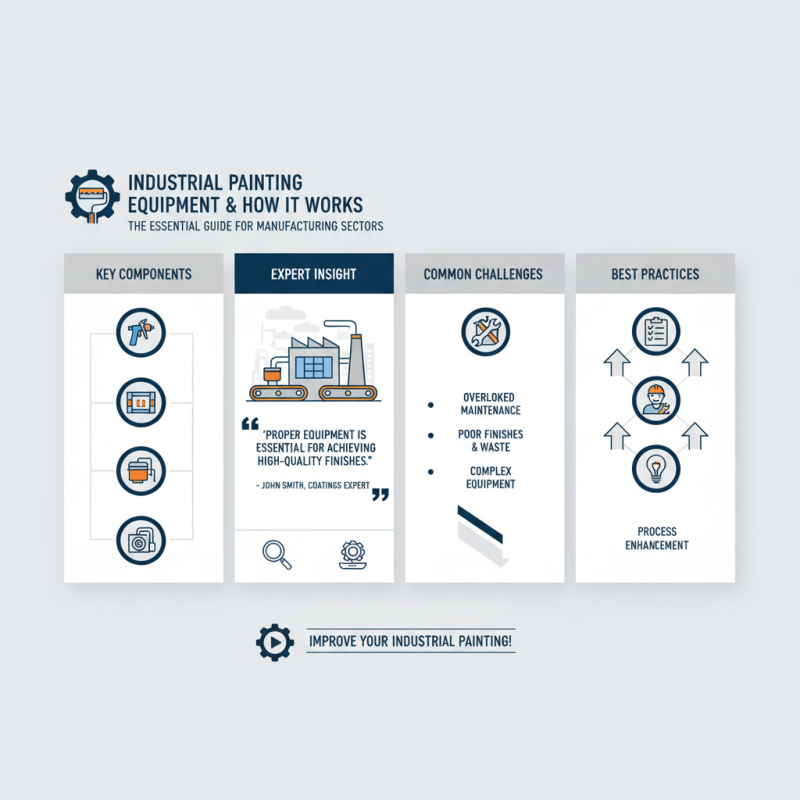

Industrial Painting Equipment plays a crucial role in numerous manufacturing sectors. It ensures that surfaces are coated effectively and uniformly. According to John Smith, an expert in industrial coatings, “Proper equipment is essential for achieving high-quality finishes.” His insight highlights the importance of using the right tools.

This equipment includes spray guns, paint booths, and mixers. Each component has a specific function. Spray guns apply paint, while paint booths control the environment. Mixers ensure the paint consistency is just right. Despite these advantages, not all companies utilize the best practices in their painting processes.

Many overlook maintenance and quality checks. Such oversights can lead to poor finishes and wasted materials. Workers may also struggle with equipment that isn't user-friendly. This can affect productivity and morale. Reflecting on these challenges is crucial for any business aiming to enhance their industrial painting efforts.

Industrial painting equipment plays a crucial role in various sectors, ensuring high-quality finishes on diverse surfaces.

At its core, it includes spray guns, paint mixers, and application systems. According to recent industry data, the global industrial painting equipment market is projected to reach $2.5 billion by 2026, demonstrating its vital importance in manufacturing and construction.

Understanding how this equipment works is essential. Spray guns create a fine mist of paint, allowing for uniform coverage. This technique minimizes paint waste and enhances efficiency. Many modern systems are designed for easy maintenance and quick color changes, making them highly adaptable for different projects. However, it is essential to consider the potential for overspray. Control measures must be in place to manage it effectively.

Tip: Always conduct a test run. This helps identify any issues before the actual application.

Furthermore, safety is paramount when using industrial painting equipment. Wearing appropriate protective gear is essential to minimize health risks. Various studies indicate that exposure to paint fumes can lead to long-term health issues. Choosing the right filtration systems can help improve working conditions. Yet, many facilities overlook these safety measures, leading to potential hazards.

Tip: Regularly inspect equipment for wear and tear. This can prevent accidents and costly downtimes.

Incorporating advanced technologies into industrial painting processes can significantly enhance performance. Features like automation can streamline operations. However, adapting to new systems can be challenging. Staff training and continuous evaluation are key to overcoming these hurdles.

Industrial painting equipment plays a crucial role in the manufacturing sector. Different types of tools are designed for various applications. For instance, spray guns are popular for their versatility. They provide a smooth finish on surfaces. Airless sprayers are another option, known for their efficiency. They work well for large areas, but can be tricky for detailed work. Another common type is powder coating systems. These systems use electrostatic charge to apply powder paint. It adheres well to metals but requires careful setup. Proper environmental controls are essential. Some painters struggle with the curing process. Improper temperatures can lead to poor results. In addition, brush and roller setups are still used. They are less common for industrial jobs but useful in certain scenarios. They allow for precision work without overspray. However, achieving a uniform coat can be challenging. Painters often find that these methods slow down the process. Each tool has its strengths and weaknesses, making the choice of equipment critical in achieving optimal results.

Industrial painting equipment plays a crucial role in various industries. It helps achieve a smooth, durable finish on surfaces. Understanding how this equipment works is essential for effective use.

The process starts with surface preparation, which is vital. Equipment like sanders or pressure washers is often used to clean and smooth surfaces. After preparation, the painting equipment applies the paint evenly. Spray guns are popular tools that atomize paint into fine droplets. This method ensures an even coat without brush marks. Observing the paint's consistency during application is important. Inconsistent texture can lead to imperfections.

Tips: Ensure your work area is well-ventilated. Proper ventilation promotes drying and reduces fumes. Remember to test the spray pattern on a scrap surface. This helps identify any adjustments needed.

Equipment maintenance is often overlooked. Clean spray guns regularly to avoid clogging. Accumulated paint can affect performance. Be vigilant about checking hoses for leaks. Small leaks can waste materials and create messy workspaces. Keep a checklist for routine inspections. This ensures longevity and efficiency.

Industrial painting equipment is essential for various sectors. It enhances efficiency and ensures a high-quality finish. These tools are designed for heavy-duty tasks. They can coat surfaces quickly and evenly.

Key features of this equipment include advanced spray technology. It allows for precise application on large surfaces. Some machines have adjustable settings for different materials and thicknesses. This flexibility helps in achieving better results. Airless sprayers are popular for their speed and coverage. They can reduce overspray and improve finish quality.

Many users overlook maintenance. Proper cleaning after each use can extend equipment life. Additionally, training staff on equipment usage is crucial. Ignoring this can lead to poor application and costly mistakes.

Tip: Always test the equipment on a small area before starting a large project. This can prevent unwanted surprises. Keep an eye on environmental conditions, as they can affect results.

When using industrial painting equipment, safety must be a top priority. Large machines and high-pressure spray guns can create hazards. These tools often produce toxic fumes. Proper ventilation is essential to minimize exposure. Workers should wear appropriate personal protective equipment (PPE). This includes masks, goggles, and gloves. Wearing these items can prevent serious health issues.

Using equipment without proper training can lead to accidents. Operators should receive instruction before handling any machines. Familiarizing oneself with equipment helps avoid common mistakes. Additionally, keeping the workspace clean reduces trip hazards. Unused materials should be stored properly to avoid spills. Regular equipment maintenance is vital for safety. A malfunctioning sprayer can create unforeseen dangers.

Conducting risk assessments is crucial. Identify potential hazards before starting work. Each painting project may have unique risks. Being aware of these risks can lead to better safety practices. It’s also beneficial to establish a clear safety protocol. Regular meetings can foster a culture of safety. Encouraging open communication about issues can make a difference.